Supply vs. Return HVAC Grilles: Healthcare Selection Guide

- By:Lisa

- 2026-01-15

- 29

In the high-stakes world of healthcare, the air we breathe is a silent ally or a hidden threat. With hospital-acquired infections (HAIs) affecting millions and leading to nearly 100,000 deaths annually in the U.S. alone, the precision of a facility’s ventilation system is non-negotiable. While massive air handlers and HEPA filters do the heavy lifting, the final point of control—the HVAC grilles—determines whether that clean air actually reaches the patient or simply bypasses them.

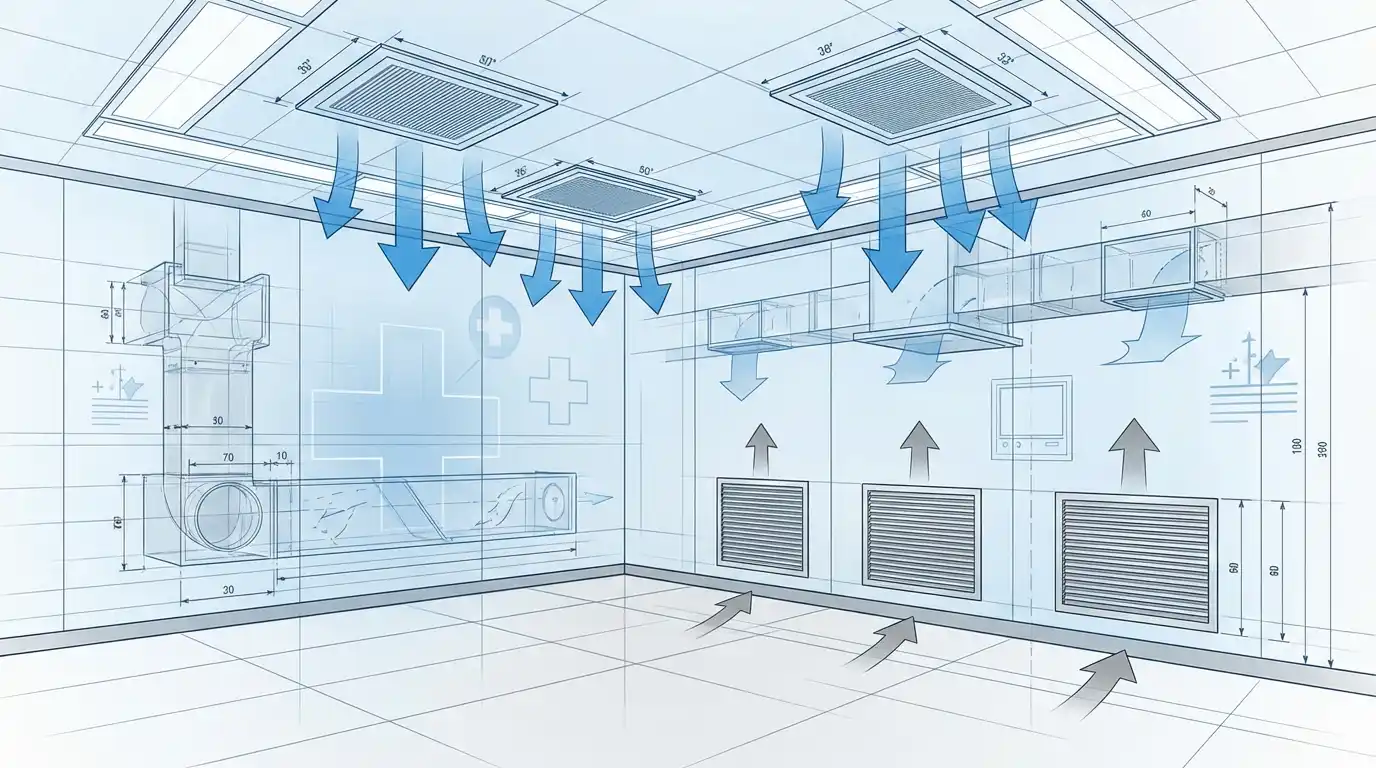

The Strategic Importance of HVAC Grilles in Infection Control

Most people see HVAC grilles as simple covers for ductwork. However, in a B2B healthcare context, they are precision-engineered instruments of infection prevention. They are the "gatekeepers" of the indoor environment, responsible for directing the path of purified air and capturing contaminants before they can settle on sterile surfaces or be inhaled by vulnerable patients.

Choosing between supply and return units isn't just a matter of airflow direction; it’s about understanding the physics of a "clean-to-dirty" airflow path. When you specify HVAC grilles, you are making a decision that impacts the facility's indoor air quality, energy efficiency, and compliance with rigorous standards like ASHRAE 170.

The Holistic Concept of Envelope Integrity

In healthcare design, we often speak of "envelope integrity." This approach, championed by industry leaders like E-ZONG, views the room as a sealed ecosystem. In this model, the HVAC grilles, the airtight automatic doors, and the wall panels work as a single team. If the grilles are high-quality but the door leaks, or if the supply vent is misplaced, the entire infection control strategy collapses. Real success comes from seeing these components not as isolated parts, but as an integrated shield for patient safety.

Supply Grilles: The Architects of Clean Air Delivery

Supply HVAC grilles are the starting point of the room's micro-climate. Their primary function is to introduce conditioned, filtered air into the space in a controlled manner. In a hospital, "controlled" means avoiding the turbulence that can stir up floor-level pathogens.

1. Unidirectional vs. Turbulent Flow

In standard office buildings, air is mixed (turbulent flow) to ensure temperature consistency. In healthcare, especially in cleanroom environments, we often require laminar flow. A laminar flow HVAC diffuser (a specialized type of supply grille) delivers air in a straight, predictable path.

- Laminar Flow: Essential for Operating Rooms. It creates a "piston" of air that pushes particles away from the surgical site.

- Non-Aspirating Flow: Used in patient rooms to prevent the "induction" of room air back into the supply stream, which could potentially re-circulate germs.

2. The Coanda Effect and Air Distribution

Strategic placement of supply HVAC grilles often utilizes the Coanda effect, where air "clings" to the ceiling surface before gently dropping into the room. This prevents direct drafts on patients—which can cause discomfort and dehydration—while ensuring that the entire volume of the room is effectively flushed with fresh air.

3. Engineering for Velocity

The face velocity of a supply grille must be meticulously balanced. If the velocity is too high, it creates noise and drafts; if it’s too low, the air "dumps" directly under the vent, leaving "dead zones" where air stagnates and bacteria can proliferate. Most healthcare designs target a face velocity between 300 and 500 feet per minute to maintain the delicate balance of air distribution.

Return Grilles: The Front Line of Contamination Capture

If supply grilles are the "delivery agents," return HVAC grilles are the "cleanup crew." Their job is to remove stale, contaminated air and move it toward the filtration system or exhaust.

1. Strategic Low-Level Placement

In many medical settings, return grilles are placed low on the wall, often near the head of the patient's bed. Why? Because many airborne pathogens are heavier than air or travel on large droplets that eventually settle. By placing vent grill units near the floor, the system "sweeps" the room from top to bottom, capturing contaminants at their source before they can migrate across the room.

2. Managing Static Pressure

A return HVAC grilles unit must have a high free area (the percentage of the grille that is open). If the free area is too small, the system encounters high static pressure, forcing the fans to work harder. This is a common issue discussed in guides regarding what a return air vent is and why it matters in HVAC.

3. Filtration at the Source

In some high-risk areas, return grilles are equipped with integrated filters or pre-filters. This prevents the ductwork itself from becoming a breeding ground for mold and bacteria, simplifying the long-term maintenance of the hospital ventilation system.

Technical Comparison: Supply vs. Return HVAC Grilles

To make the right selection, facility managers must understand the technical nuances that separate these two components.

| Feature | Supply HVAC Grilles | Return HVAC Grilles |

|---|---|---|

| Primary Goal | Direct clean air and maintain pressure. | Extract contaminated air and odors. |

| Airflow Pattern | Focused, directional, or spread. | Non-directional, high-volume pull. |

| Common Materials | Stainless steel grilles or aluminum. | High-strength aluminum or steel. |

| Typical Location | Ceilings or high-wall placement. | Low-wall or ceiling (depending on room type). |

| Key Metric | Throw and Spread of the air. | Free Area and Static Pressure. |

| Cleaning Needs | Prevent dust buildup from blowing out. | Clear captured debris and aerosols. |

Pressure Differentials: The Silent Force of Containment

The interaction between supply and return HVAC grilles is what creates pressure differentials. This is the most critical aspect of infection control in B2B healthcare environments.

Positive Pressure Rooms (Protective Environments)

In an OR or a pharmacy compounding room, we use positive pressure. This means the supply HVAC grilles pump in more air than the return grilles take out. The result? Air always leaks out of the room through gaps or when doors open, ensuring that no outside contaminants can sneak in.

Negative Pressure Rooms (Airborne Infection Isolation)

In rooms housing patients with contagious diseases like TB or COVID-19, the return HVAC grilles pull more air out than the supply vents provide. This creates a vacuum effect, ensuring that the air from the infected patient is trapped within the room and sent directly to a HEPA exhaust system.

The Role of Air Change Rates

Regulatory bodies like ASHRAE Standard 170 mandate specific air change rates for different clinical areas. For example, an OR might require 20 ACH, while a standard ward needs 6. The sizing and quantity of your HVAC grilles are the primary variables used to hit these targets without causing excessive air noise.

Materials Science: Why "Medical Grade" Matters

In a residential setting, a plastic or thin steel vent is sufficient. In healthcare, it will fail within months. The cleaning agents used in hospitals—often chlorine-based or hydrogen peroxide vapors—are incredibly corrosive.

1. Aluminum vs. Stainless Steel

- Aluminum Profiles: High-quality aluminum profiles are the industry standard. They are lightweight, naturally resistant to rust, and can be extruded into complex shapes for better airflow control.

- 304/316 Stainless Steel: For the most demanding environments, such as sterile processing departments, stainless steel grilles are required. They can withstand the most aggressive sterilization protocols without "pitting," which is where bacteria often hide.

2. Antimicrobial Coatings

Modern HVAC grilles often feature an antimicrobial coating. These specialized finishes contain silver ions or other agents that actively kill 99.9% of bacteria on contact. This adds an extra layer of defense, preventing the grille itself from becoming a reservoir for HAIs.

3. Precision Manufacturing

A B2B supplier should offer CNC precision in their manufacturing. Gaps in the frame or loose blades aren't just an aesthetic issue; they are air-leaks that can compromise room pressure. E-ZONG’s commitment to precision ensures that every grille fits perfectly within the "envelope," maintaining the airtight seal required for high-performance medical spaces.

Selection Guide: Matching Grilles to Specific Clinical Zones

Every square foot of a hospital has a different requirement for airflow management. Here is a breakdown of how to choose HVAC grilles based on the zone.

The Operating Room

The OR is the most sensitive area in any hospital. Here, we prioritize unidirectional flow and sterility.

- Supply: Use a laminar flow HVAC diffuser integrated with HEPA filtration.

- Return: Multiple low-level returns positioned around the perimeter to ensure the "piston" of air moves vertically through the entire room.

Isolation Rooms

- Protective Environment: Positive pressure supply to protect immuno-compromised patients.

- Airborne Infection Isolation: Strong negative pressure via return grilles to contain pathogens.

Hospital Pharmacies and Labs

In these spaces, contamination control is the priority. Small particles can ruin a batch of medication or cross-contaminate a lab sample.

- Selection: Use ceiling vents with adjustable dampers to allow for fine-tuning of the air balance during the commissioning phase.

Patient Wards and Corridors

Comfort and odor control are the main goals here.

- Selection: Multi-directional supply grilles that provide a wide spread of air to avoid "hot spots" or "cold spots."

Compliance and Regulatory Standards

Navigating the legal requirements of healthcare ventilation is a complex task for any facility manager. Your choice of HVAC grilles must satisfy several governing bodies:

- ASHRAE Standard 170: The primary code for ventilation of healthcare facilities. It dictates the velocity, placement, and ACH for every room type.

- CDC Guidelines: These focus on the clinical outcomes, specifically how airflow patterns affect the transmission of diseases like Aspergillus or Legionella.

- FGI Guidelines: The Facility Guidelines Institute provides the "minimum standards" for the physical environment, including material durability and cleanability of HVAC vents.

- ISO 14644: For hospital pharmacies and labs that operate as cleanrooms, these standards define the allowable particle counts per cubic meter.

[Image: Table of ASHRAE 170 Air Change Requirements for various hospital rooms]

Installation and Maintenance: The Keys to Longevity

Even the best HVAC grilles will underperform if they are poorly installed or neglected. In a B2B environment, "set it and forget it" is a recipe for disaster.

1. The Importance of Gasketing

Air should only pass through the blades of the grille, not around the frame. High-quality healthcare grilles use medical-grade gaskets to create an airtight seal against the ceiling or wall. This prevents "plenum air"—which is often unfiltered—from leaking into the sterile room.

2. Balancing the System

After installation, a Testing, Adjusting, and Balancing (TAB) professional must verify the airflow. If your HVAC grilles don't feature accessible damper controls, this process becomes a nightmare, often requiring the removal of ceiling tiles and risking the introduction of dust into a clean area.

3. Cleaning Protocols

Hospitals should have a quarterly cleaning schedule for all vent grill units.

- Visual Inspection: Look for "smudging" around the edges, which indicates air bypass or poor filtration.

- Wipe-Down: Use approved disinfectants. Ensure the grille design has smooth, radius corners to allow for easy cleaning of every surface.

- Filter Swaps: If the grille is a filter-return type, ensure the filters are changed according to the pressure-drop sensors.

5 Critical Mistakes to Avoid When Specifying HVAC Grilles

Drawing from nearly 30 years of industry experience, we’ve identified five common pitfalls in healthcare air management:

- Using Non-Medical Grade Materials: Residential-grade steel will rust and harbor bacteria. Always specify medical-grade materials like anodized aluminum or 316 stainless steel.

- Ignoring Sound Power Levels: A noisy grille increases patient stress and can lead to "alarm fatigue" for nurses. Check the Noise Criteria rating of every unit.

- Inadequate Face Area: Sizing a return grille too small leads to high-velocity "suction" that can be noisy and energy-inefficient.

- Improper Throw Distance: If a supply grille’s "throw" is too long, the air hits the opposite wall and creates a swirling effect, destroying the clean-to-dirty airflow path.

- Neglecting the "Total Envelope": Buying grilles from one vendor and doors from another often leads to compatibility issues. Integrated solutions from a single-source provider like E-ZONG ensure that the envelope integrity is maintained.

Beyond the Basics: Advanced Airflow Modeling

For complex projects like hybrid ORs or large-scale isolation wards, simple calculations aren't enough. Many top-tier B2B consultants now use Computational Fluid Dynamics (CFD).

CFD modeling allows designers to see a virtual 3D map of how air will move through a room before a single duct is installed. It can identify "stagnant air pockets" and show exactly how the placement of HVAC grilles will influence the path of a simulated pathogen. By investing in this modeling phase, healthcare facilities can avoid costly retrofits and ensure 100% compliance from day one.

Conclusion

The debate of supply vs. return HVAC grilles is the foundation of a safe, compliant healthcare environment. By selecting the right materials and understanding the physics of pressure, you can transform your ventilation system into a powerful tool for infection prevention.

Ready to elevate your facility's air management strategy?

Whether you are designing a new surgical wing or upgrading an existing isolation ward, our team of experts is ready to assist. To avoid common pitfalls, review our guide on cleanroom design mistakes and how to avoid them.

-

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment -

Top Aluminium Profile Manufacturers in China: Leading the Global Market

Top Aluminium Profile Manufacturers in China: Leading the Global Market -

The Evolution of Air Tight Sliding Doors

The Evolution of Air Tight Sliding Doors -

AHU Aluminium Profile: A Comprehensive Guide

AHU Aluminium Profile: A Comprehensive Guide -

The Importance of Choosing the Right Cleanroom Door in Vietnam

The Importance of Choosing the Right Cleanroom Door in Vietnam -

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety -

.jpg) The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities!

The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities! -

Unlock the Possibilities with AJ Manufacturing Doors

Unlock the Possibilities with AJ Manufacturing Doors -

Make a Statement with Manufactured Home Interior Doors!

Make a Statement with Manufactured Home Interior Doors! -

what is aluminum profile? Aluminum Profiles for Your Home is the best option

what is aluminum profile? Aluminum Profiles for Your Home is the best option

-

Supply vs. Return HVAC Grilles: Healthcare Selection Guide

Supply vs. Return HVAC Grilles: Healthcare Selection Guide -

Linear Diffuser: The Secret to Modern HVAC Comfort & Design

Linear Diffuser: The Secret to Modern HVAC Comfort & Design -

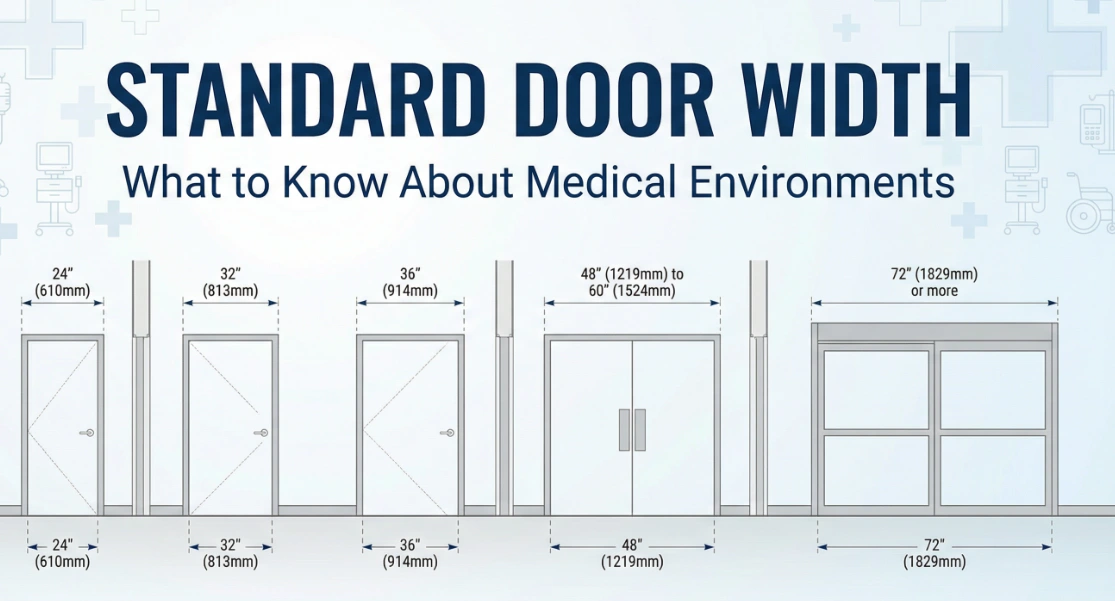

What to Know About Standard Door Width in Medical Environments

What to Know About Standard Door Width in Medical Environments -

What Is a Return Air Vent and Why Does It Matter in HVAC

What Is a Return Air Vent and Why Does It Matter in HVAC -

Top Materials for Durable Pharma Clean Room Doors

Top Materials for Durable Pharma Clean Room Doors -

Hospital Cleanroom Door Design Requirements

Hospital Cleanroom Door Design Requirements -

Swing Doors vs Standard Doors: Which Is Right for Your Facility

Swing Doors vs Standard Doors: Which Is Right for Your Facility -

Cleanroom Door Materials Explained: Key Types and Applications

Cleanroom Door Materials Explained: Key Types and Applications -

How Do Different Vent Grills Impact Medical Cleanrooms

How Do Different Vent Grills Impact Medical Cleanrooms -

Controlled Environment vs Air Clean Room Differences Explained

Controlled Environment vs Air Clean Room Differences Explained

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.

Speak Your Mind