Clean room aluminum profile solutions

The aluminum profiles in the purification workshop are called purified aluminum profiles. The biggest purpose of the purification workshop is to ensure that the cleanliness of the product production environment meets certain requirements, so there are more requirements for the assembly materials.

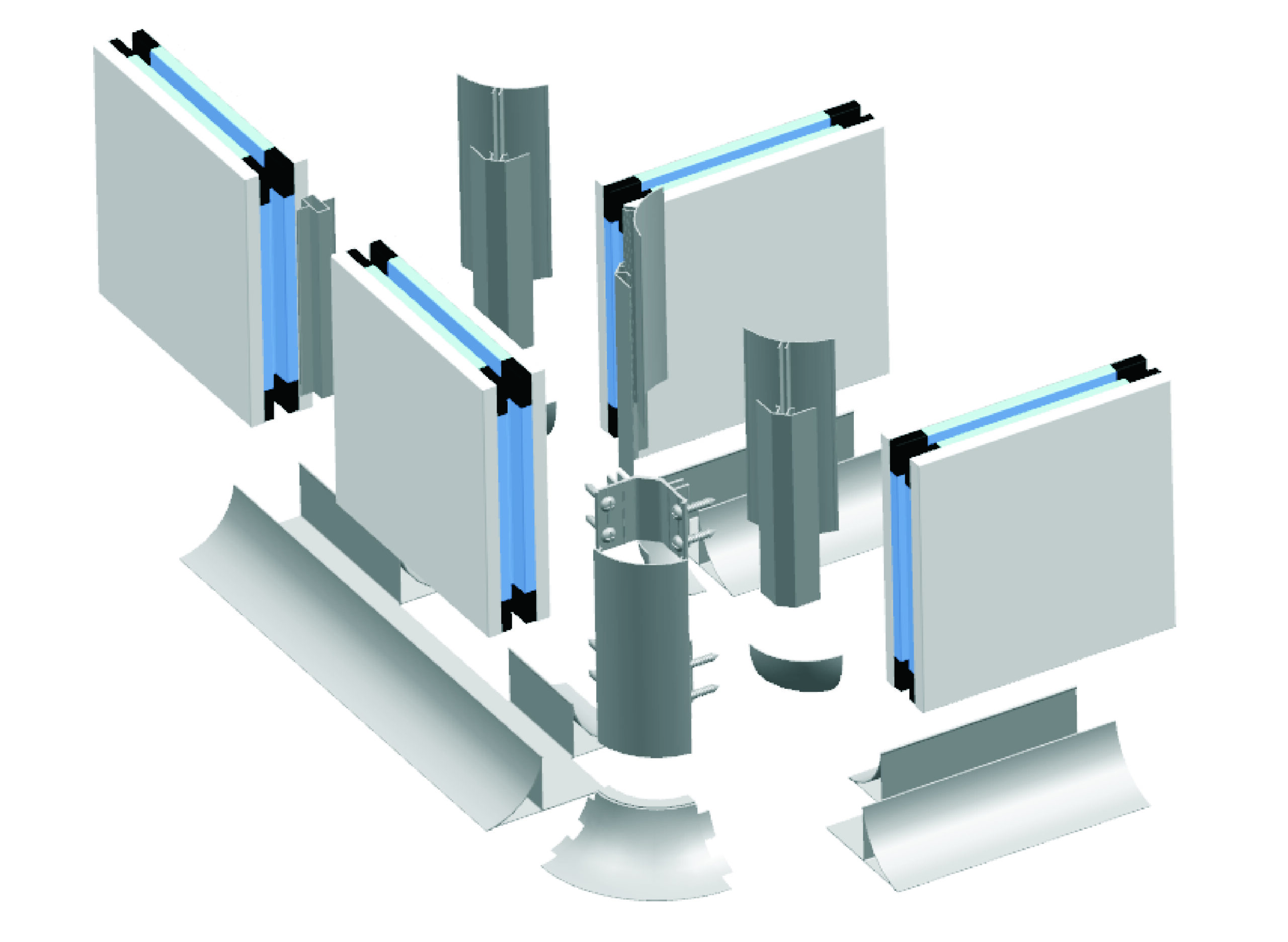

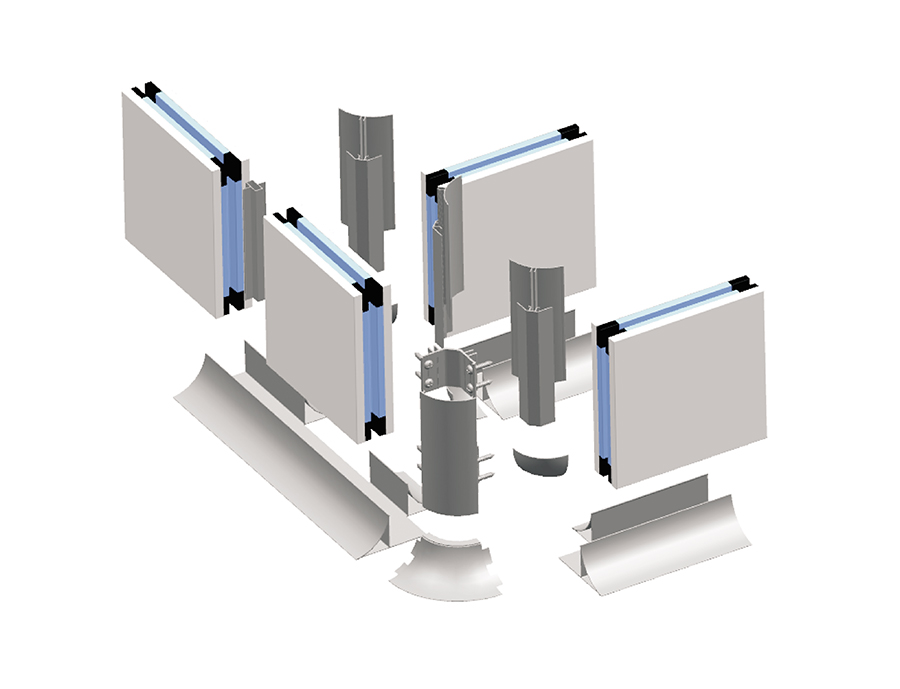

A cleanroom aluminum profile is a specialized type of aluminum extrusion used in locations where cleanliness and sanitation are of utmost importance. This type of profile is used in laboratory settings and in medical and industrial production environments where airborne particles must be minimized. It is typically used for making frames, door panels, and other components such as shelves, drawers and cabinets. Cleanroom aluminum profiles provide a secure and sanitary way to keep a controlled environment.

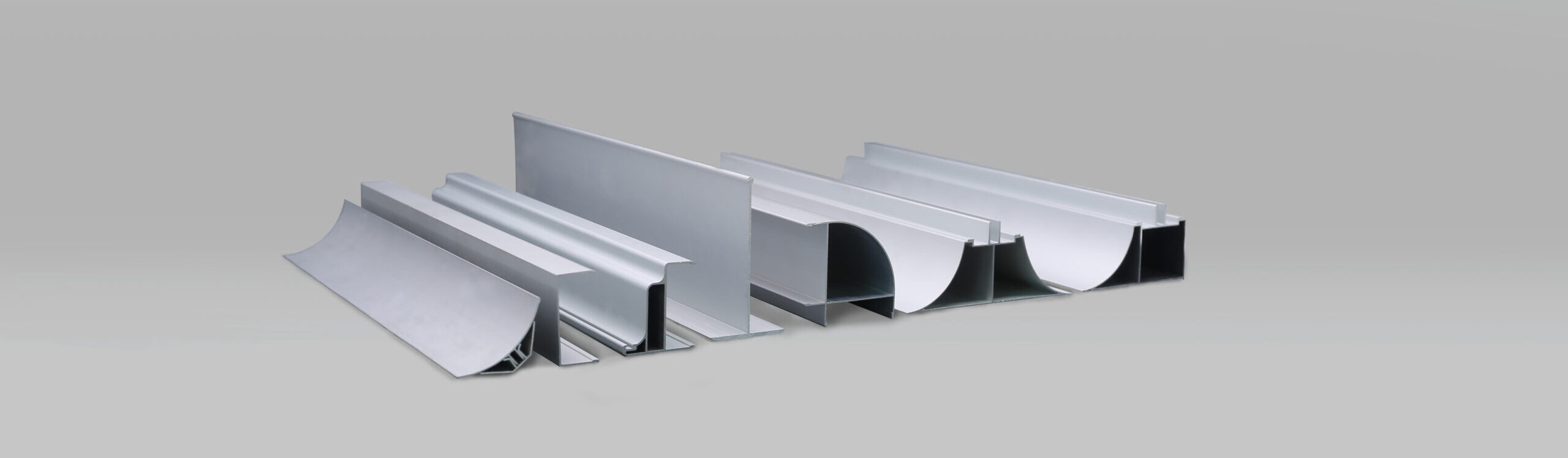

Purified aluminum profiles

First of all, it is necessary to ensure that the material must have special effects of oxidation resistance and corrosion resistance. The surface of the purified aluminum profiles material is oxidized to effectively prevent the possibility of oxidation. In some laboratories, it is necessary to use some chemicals, which have strong chemical reactions. Common steel products or untreated aluminum products obviously do not meet the requirements, and only oxidized materials can be used.

Purified aluminum profiles is extruded, and the surface is anodized to eliminate the possibility of oxidation with other chemical components. Become a ubiquitous product in cleanrooms.

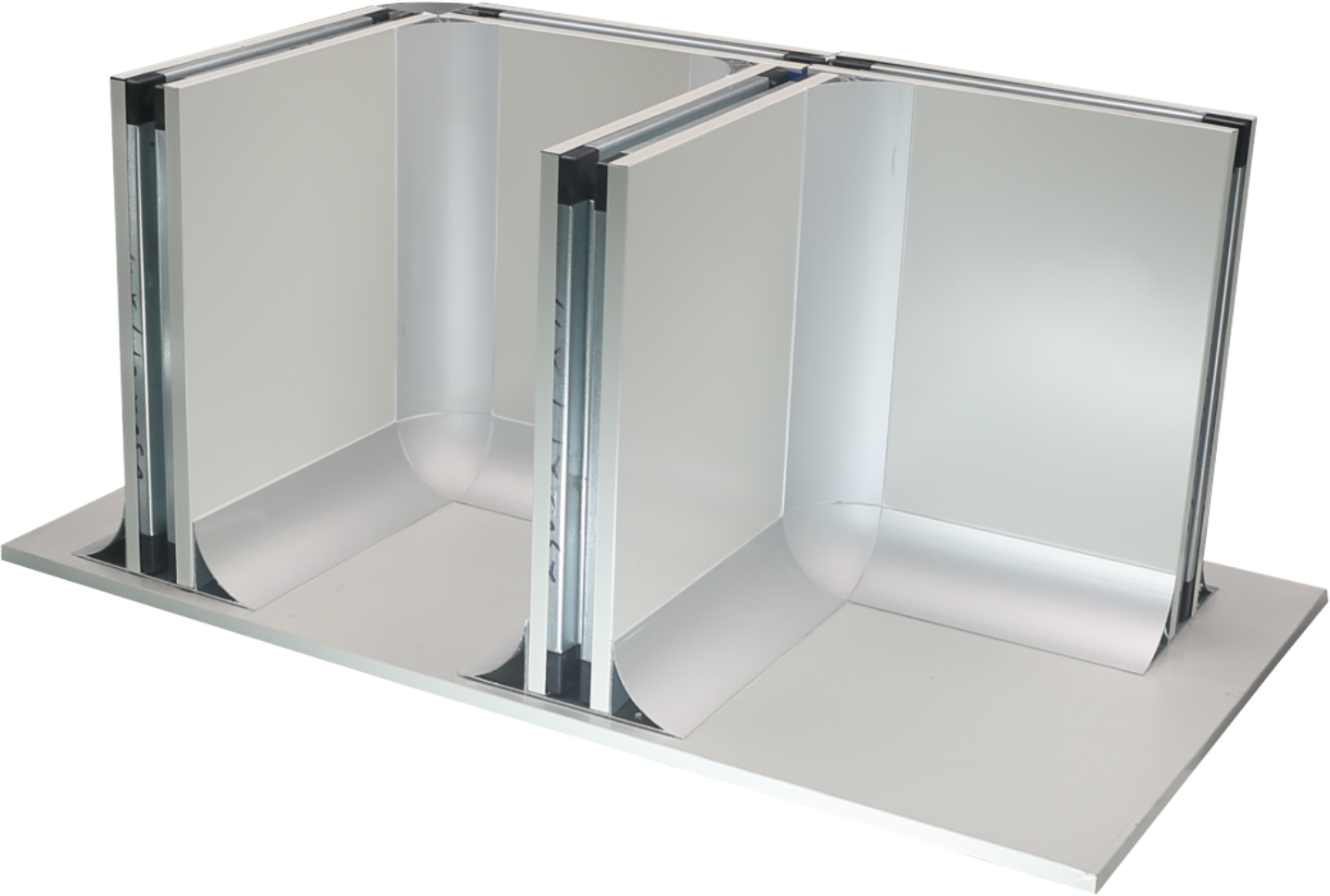

In terms of design, it adopts component installation, which greatly enhances its flexibility. It is directly extruded, without electric welding, and has a beautiful and generous appearance. According to the requirements of the clean room, taking into account the dust removal requirements, try to build a workshop without dead ends as much as possible, so that the dust can be removed more simply and conveniently, so as to improve the cleanliness!

Features: good quality, good strength, easy processing, beautiful appearance, as for various surface treatments, good corrosion resistance, weather resistance, chemical resistance, good thermal conductivity, good electrical conductivity, non-magnetic, low temperature resistance.

Cleanroom aluminum profile is commonly used to make frames and barriers for cleanrooms or other environments that must remain free of contaminants. This type of profile is designed with rounded edges and a smooth, clean surface to help prevent the buildup and accumulation of impurities. Cleanroom aluminum profile can also be customized with various finishes, colors, and surface treatments, ensuring that the exact profile is created to suit the requirements of any specific environment. These profiles are highly resistant to corrosion and can withstand extreme temperatures, making them ideal for many applications in the medical, pharmaceutical, aerospace, and industrial sectors.

Common problem

1. Corrosion: Debris and dust can accumulate on the aluminum profiles, leading to corrosion and oxidation.

2. Improper Sealing: Improperly sealed aluminum profiles in the clean room will allow dust, debris, and other particles to get into the room.

3. Lack of Finishing: Poor finishing of aluminum profiles in the room can make them more prone to dust and dirt. Poor finishes may also lead to metal fatigue and failure.

4. Poor Durability: The use of low-grade materials can result in poor durability and failure.

5. Temperature Changes: Aluminum profiles in clean room environments are prone to thermally-induced stresses due to extreme temperature changes. This can lead to corrosion, fatigue, and ultimately failure.

Solution: Compliant with standards, worry-free use

1. Profile Sections: Aluminum profiles are suitable for use in clean rooms due to their corrosion resistance and ability to form tight seals that prevent dust particles and other contaminants from entering the cleanroom. The profile section should be made from extruded or anodized aluminum alloy that is electrostatically formed or bead blasted to minimize surface irregularities.

2. Fabrication: Aluminum profiles can be cut and bent to specific shapes, reducing the amount of metal contact surfaces exposed to the environment and reducing the chance of particles becoming entrapped in sharp corners and crevices.

3. Finishing: Anodization of aluminum surfaces creates a protective layer that provides a higher degree of resistance to oxidation and abrasion. This layer can also improve surface appearance and reduce the risk of contamination.

4. Sealing: By combining several aluminum profiles, it is possible to create a complete and effective airtight seal, which is essential in a clean room environment. This is achieved by applying sealing compounds to ensure that any gaps or irregularities in the jointing system of the profiles are sealed.

5. Installation: Care should be taken when installing aluminum profiles in a cleanroom to ensure that all parts are compatible and that any cuts and bends are smooth and consistent. Any joints should be sealed carefully and the final assembly should be fitted with the necessary hardware and screws to reduce the risk of breakdown or contamination.

Professional Customization, High-Quality Service

Highlights of E-ZONG customized aluminum profiles

As we all know, aluminum customization requires a variety of craftsmanship and superb technology. As a high-quality aluminum profile manufacturer with more than 20 years of experience, E-ZONG understands the technical difficulties in the aluminum profile production process, which can help you solve the problems encountered in aluminum profile customization more efficiently.

E-ZONG has a professional design and development team, which can provide customers with customized aluminum services according to customer needs, quickly produce drawings, and save the complicated process of design drawings.

At the same time, E-ZONG continues to introduce industry-leading management models and production equipment, and always focuses on creating environmentally friendly aluminum materials and products that lead the trend of the times with precision standards. Advanced production equipment, scientific process, precise control, and strict quality inspection make aluminum profiles not easy to collapse and damage, have a longer service life, and are superior in quality to other manufacturers. E-ZONG also has more advantages in the collocation and use of aluminum profile accessories. Through the supporting production of aluminum profiles, the cost is greatly reduced, and the quality and progress of the project are guaranteed.

If you have custom requirements for aluminum profiles, welcome to consult online, E-ZONG sincerely looks forward to cooperating with you!

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.