2024 Maintaining Sterility: Sliding Doors Solutions for Clean Room Environments

- By:hqt

- 2024-03-13

- 29

Clean rooms are essential controlled environments utilized across diverse industries such as medical and health, bio-pharmaceutical, food and beverage, cosmetics, machinery, and electronics. These specialized environments are meticulously designed to maintain stringent levels of cleanliness and sterility to ensure product quality, safety, and regulatory compliance. Among the key components contributing to the integrity of clean room environments, sliding doors play a pivotal role.

Understanding Industry Needs

1.1 Requirements for Cleanliness and Sterility

In the medical and health sector, clean rooms are imperative for surgeries, research labs, and pharmaceutical compounding facilities to prevent contamination and ensure patient safety. Bio-pharmaceutical industries require sterile environments to produce vaccines, biologics, and other critical medications. Similarly, the food and beverage industry relies on clean rooms to maintain hygiene standards and prevent microbial contamination in production processes. In cosmetics manufacturing, clean rooms are essential for product formulation and packaging to ensure consumer safety. In machinery and electronics, clean rooms protect sensitive equipment from dust and particulate contamination, ensuring optimal performance and longevity.

1.2 Impact of Contamination

Contamination in clean rooms can have severe consequences across industries. In medical settings, microbial contamination can lead to healthcare-associated infections (HAIs), compromising patient health and safety. In bio-pharmaceutical production, even minor contaminants can disrupt cell cultures or compromise product purity, leading to costly production delays or recalls. Contamination in food and beverage manufacturing can result in product spoilage, recalls, and potential health risks for consumers. In electronics and machinery, dust and particulate contamination can cause equipment malfunction, affecting product quality and reliability.

Challenges Faced

2.1 Common Challenges

Maintaining cleanliness and sterility in clean room environments presents numerous challenges. Controlling air quality and particulate contamination is paramount, requiring sophisticated filtration systems and strict protocols for personnel and equipment entry. Personnel movement within clean rooms must be carefully managed to minimize the risk of contamination, necessitating specialized training and adherence to strict gowning procedures.

2.2 Air Quality and Particulate Control

Airborne contaminants pose a significant challenge in clean room environments. Even microscopic particles can compromise product quality and safety. Effective particulate control requires high-efficiency particulate air (HEPA) filters, laminar airflow systems, and constant monitoring to maintain specified cleanliness levels.

2.3 Personnel Movement

Human activity is a primary source of contamination in clean rooms. Personnel must undergo rigorous training and adhere to strict protocols for gowning, hand hygiene, and movement within clean room facilities. Implementing air showers, gowning rooms, and designated entry points helps minimize the risk of contamination from personnel.

Sliding Doors Solutions

3.1 Essential Component of Clean Room Design

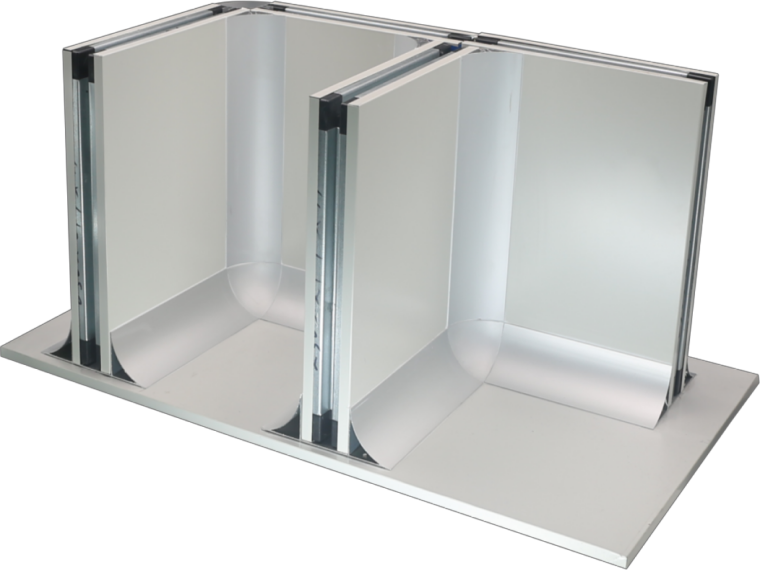

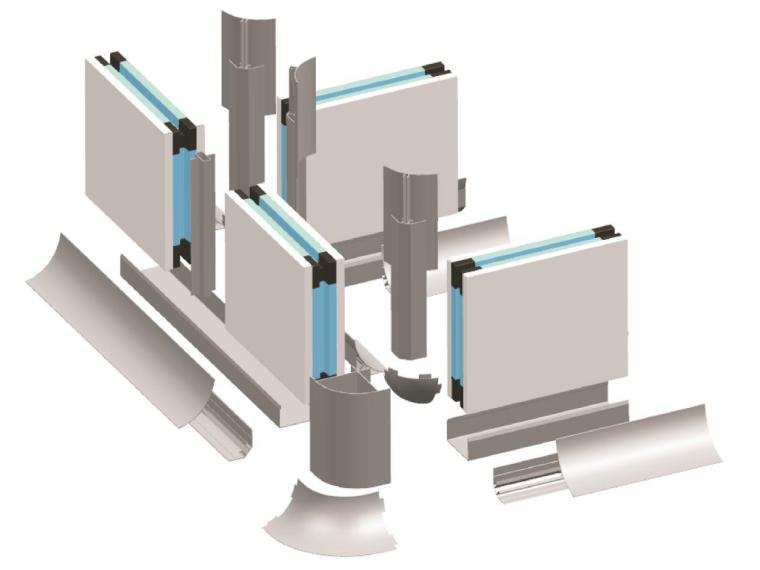

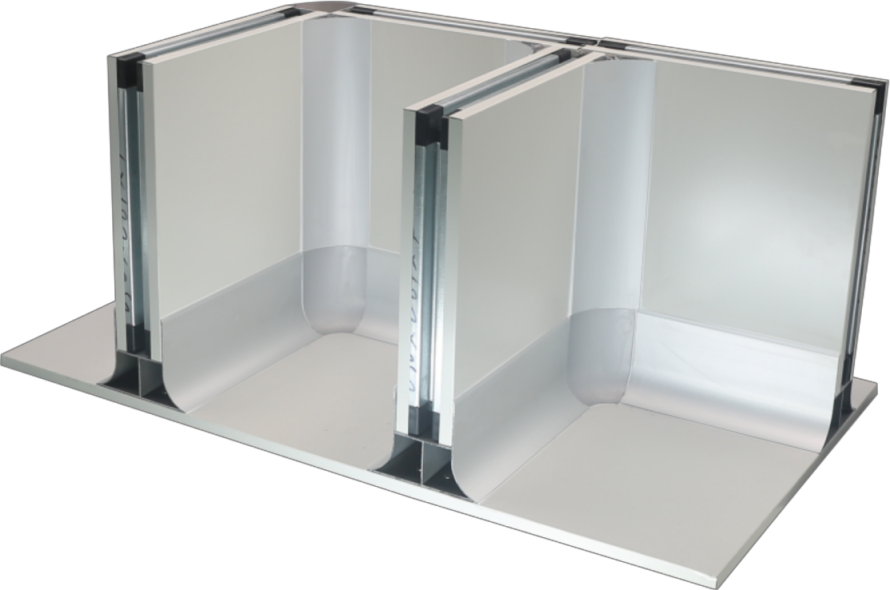

Sliding doors are indispensable components of clean room design, providing controlled access while minimizing the risk of contamination. E-ZONG, a leading manufacturer of sliding doors for clean room applications, offers a range of solutions tailored to meet the unique requirements of various industries.

3.2 Types of Sliding Doors

E-ZONG provides an array of sliding door options, including manual, automatic, and hermetically sealed doors. Manual sliding doors are ideal for areas with lower traffic volume, offering reliable performance and ease of operation. Automatic sliding doors feature motion sensors for hands-free operation, enhancing convenience and minimizing the risk of cross-contamination. Hermetically sealed sliding doors provide an airtight barrier, ensuring optimal cleanliness and sterility in critical environments.

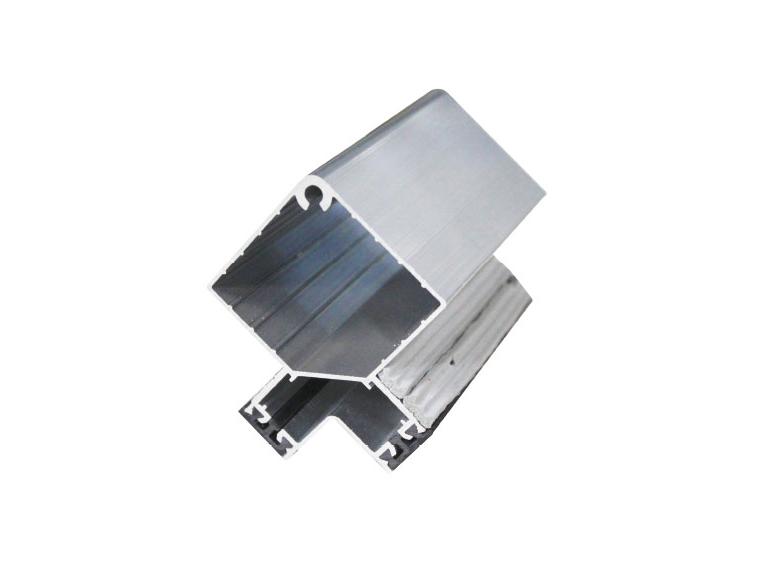

3.3 Key Features

E-ZONG sliding doors are equipped with air-tight seals to prevent air leakage and maintain specified cleanliness levels. The smooth operation ensures quiet and efficient performance, minimizing disruptions in clean room environments. E-ZONG sliding doors are constructed from durable materials such as stainless steel or aluminum, ensuring compatibility with stringent clean room requirements and facilitating easy cleaning and maintenance.

Application Examples

1. Medical and Health: E-ZONG sliding doors have been crucial in medical settings, providing a barrier against contamination in operating rooms, research labs, and pharmaceutical compounding facilities. By ensuring sterility, these doors contribute to patient safety and infection control protocols.

2. Bio-pharmaceutical: In bio-pharmaceutical manufacturing, E-ZONG sliding doors play a vital role in maintaining clean room integrity during the production of vaccines, biologics, and other critical medications. These doors address the specific challenges of contamination control, ensuring product purity and regulatory compliance.

3. Food and Beverage: Clean rooms equipped with E-ZONG sliding doors are essential for maintaining hygiene standards in food and beverage production. These doors help prevent microbial contamination, safeguarding the quality and safety of consumable products.

4. Cosmetics: E-ZONG sliding doors are utilized in clean room environments for cosmetics manufacturing, ensuring the purity and safety of skincare and beauty products. By minimizing contamination risks, these doors contribute to product quality and consumer satisfaction.

5. Machinery and Electronics: In industries such as machinery and electronics, clean rooms with E-ZONG sliding doors protect sensitive equipment from dust and particulate contamination. This ensures optimal performance, reliability, and longevity of machinery and electronic components.

Challenges Addressed and Benefits Realized

1. Challenges: Controlling air quality and particulate contamination, managing personnel movement to minimize the risk of contamination, and ensuring compliance with strict cleanliness and sterility standards are common challenges faced by industries in clean room environments.

2. Benefits: E-ZONG sliding doors address these challenges by providing air-tight seals, smooth operation, and compatibility with stringent clean room requirements. These doors enhance contamination control, improve operational efficiency, and support regulatory compliance, ultimately safeguarding product quality and safety.

Future Trends and Innovations

1. Automated Systems: Emerging trends in sliding door technology include automated systems equipped with smart sensors for hands-free operation. These systems enhance convenience, minimize the risk of cross-contamination, and optimize workflow efficiency in clean room environments.

2. Improved Materials: Advancements in materials science are driving innovations in sliding door design, with a focus on durability, compatibility with clean room requirements, and ease of maintenance. E-ZONG remains at the forefront of these developments, continuously improving its products to meet evolving industry needs.

3. Smart Sensors: Integration of smart sensors enables real-time monitoring of environmental conditions, allowing for proactive maintenance and optimization of clean room performance. E-ZONG is exploring the integration of smart sensor technology into its sliding door solutions to enhance functionality and reliability.

Why Choose E-ZONG

E-ZONG's extensive experience, commitment to quality, and dedication to customer satisfaction make it the preferred choice for sliding door solutions in clean room environments. With state-of-the-art manufacturing facilities and a team of experienced technicians and manufacturing workers, E-ZONG delivers innovative, reliable, and economical solutions tailored to meet the unique requirements of each industry.

Conclusion

In conclusion, sliding doors play a crucial role in maintaining the integrity of clean room environments across diverse industries. E-ZONG's innovative solutions offer reliable performance, enhanced functionality, and optimal cleanliness and sterility, contributing to the success and safety of clean room operations. By addressing the specific challenges faced by industries and providing tailored solutions, E-ZONG continues to be a trusted partner in clean room design and construction.

-

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment -

Top Aluminium Profile Manufacturers in China: Leading the Global Market

Top Aluminium Profile Manufacturers in China: Leading the Global Market -

The Evolution of Air Tight Sliding Doors

The Evolution of Air Tight Sliding Doors -

AHU Aluminium Profile: A Comprehensive Guide

AHU Aluminium Profile: A Comprehensive Guide -

The Importance of Choosing the Right Cleanroom Door in Vietnam

The Importance of Choosing the Right Cleanroom Door in Vietnam -

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety -

.jpg) The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities!

The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities! -

Unlock the Possibilities with AJ Manufacturing Doors

Unlock the Possibilities with AJ Manufacturing Doors -

Make a Statement with Manufactured Home Interior Doors!

Make a Statement with Manufactured Home Interior Doors! -

what is aluminum profile? Aluminum Profiles for Your Home is the best option

what is aluminum profile? Aluminum Profiles for Your Home is the best option

-

Designing a Flexible Clean Room Aluminum Profile System

Designing a Flexible Clean Room Aluminum Profile System -

Look for in Cleanroom Aluminum Profile Wholesaler. Here to Know

Look for in Cleanroom Aluminum Profile Wholesaler. Here to Know -

HVAC Air Diffusion Products Myths Debunked: What You Really Need to Know

HVAC Air Diffusion Products Myths Debunked: What You Really Need to Know -

Why Opt Aluminum Profiles For Air Handling Units: Custom Service

Why Opt Aluminum Profiles For Air Handling Units: Custom Service -

Understanding Doors & Windows for Cleanrooms Seals Solutions:

Understanding Doors & Windows for Cleanrooms Seals Solutions: -

Options for Doors in a Cleanroom: Which Type is Right for You?

Options for Doors in a Cleanroom: Which Type is Right for You? -

6 Considerations In Choosing Clean Room Doors

6 Considerations In Choosing Clean Room Doors -

Cleanroom Doors Sliding Doors: Which Is Best for Your Facility?

Cleanroom Doors Sliding Doors: Which Is Best for Your Facility? -

Choosing the Right Hygienic Doors for Your Facility

Choosing the Right Hygienic Doors for Your Facility -

Cleanroom Aluminum Profile Wholesale Market: Key Trends and Insights

Cleanroom Aluminum Profile Wholesale Market: Key Trends and Insights

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.

Speak Your Mind