Cleanroom Aluminum Profile Wholesale Market: Key Trends and Insights

- By:hqt

- 2024-09-13

- 29

Present Market Dynamics and Demand in the Wholesale of Cleanroom Aluminum Profiles

The marketplace for cleanroom aluminum profiles is currently witnessing a considerable upsurge, significantly propelled by the escalating demand for cleanrooms across a broad spectrum of industries, including but not limited to pharmaceuticals, semiconductors, biotechnology, and healthcare. The intensifying focus on sustaining contamination-free environments within these sectors has inevitably led to a burgeoning necessity for top-tier cleanroom construction materials, among which aluminum profiles play a pivotal role.

Escalating Demand Across Various Sectors

Notably, the pharmaceutical and semiconductor industries stand out as primary drivers behind the escalating demand for cleanroom aluminum profiles. In the realm of pharmaceuticals, cleanrooms are indispensable for the production of sterile medications and medical devices, where any contamination could prove catastrophic. Conversely, the semiconductor industry, characterized by its need for ultra-clean environments for the fabrication of microchips and other electronic components, further amplifies the demand. As these industries continue their upward trajectory, the corresponding need for cleanroom aluminum profiles has risen in tandem, thereby fostering a thriving market for wholesale suppliers.

Technological Progressions in Cleanroom Construction

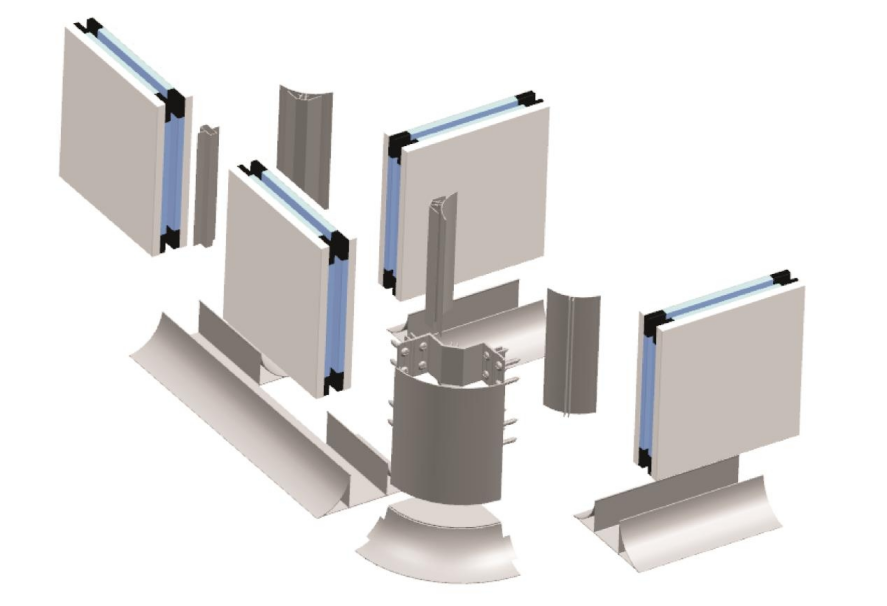

The ongoing technological advancements within the sphere of cleanroom construction have further fueled the expansion of the aluminum profile market. The advent of modular cleanrooms, which facilitate faster and more adaptable construction, has necessitated the availability of custom aluminum profiles, specifically designed to cater to unique project requirements. Wholesale suppliers are increasingly concentrating their efforts on offering profiles that not only adhere to these sophisticated specifications but also align with the most recent industry standards and technological advancements.

Influence of Global Supply Chain Dynamics

The dynamics of the global supply chain wield a profound influence on the accessibility and pricing of cleanroom aluminum profiles. With a significant number of suppliers operating out of Asia, particularly from China, the fluctuations in global trade policies, availability of raw materials, and transportation expenses exert a considerable impact on the wholesale market. Suppliers such as E-ZONG play a crucial role in ensuring a consistent supply of high-quality aluminum profiles, thereby addressing the growing global demand.

Crucial Considerations in the Wholesale of Cleanroom Aluminum Profiles

Engaging in the wholesale distribution of cleanroom aluminum profiles necessitates careful consideration of several critical factors, ensuring that the products are not only compliant with the stringent requirements of cleanroom environments but also tailored to meet the specific needs of diverse industries.

Adherence to Quality Standards and Compliance

Among the most pivotal considerations is the adherence of aluminum profiles to stringent quality standards and their compliance with international regulations. Cleanroom environments demand materials that conform to precise cleanliness and durability criteria, such as those established by the International Organization for Standardization (ISO). It is imperative for wholesale suppliers to guarantee that their products are manufactured using premium-grade materials and processes that not only meet but often exceed these standards, thereby ensuring the preservation of the cleanroom's integrity.

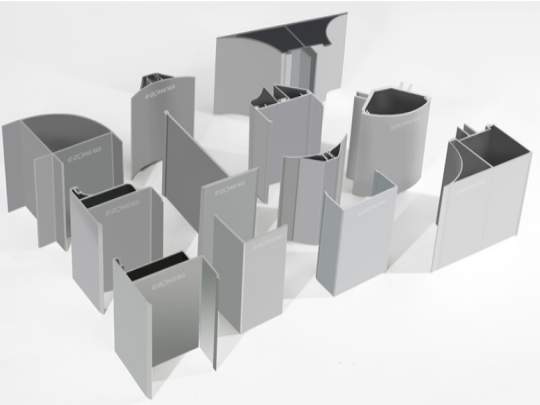

Importance of Customization and Versatility

Given the distinct requirements of various cleanroom projects, the capacity for customization in aluminum profiles emerges as a crucial consideration. Wholesale suppliers are expected to provide an extensive array of profile shapes, dimensions, and finishes, thus accommodating a wide range of construction needs. Features such as T-slots, which facilitate modular design configurations, significantly enhance the profiles' versatility, making them seamlessly integrated with other systems within the cleanroom.

Ensuring Supply Chain Dependability

In the context of wholesale, the dependability of the supply chain is a paramount concern. Suppliers must ensure that they possess the capability to consistently deliver high-quality products promptly, effectively meeting their clients' demands. This necessitates the maintenance of a robust inventory, the implementation of efficient production processes, and the establishment of reliable logistics. Furthermore, suppliers must be adept at navigating any potential disruptions within the global supply chain, whether these arise from economic fluctuations, natural disasters, or shifts in trade policies.

Customization Strategies for Cleanroom Aluminum Profile Wholesale

Customization plays a vital role in cleanroom construction, enabling companies to tailor their environments to meet specific operational requirements. Wholesale suppliers are instrumental in delivering customized aluminum profiles that precisely align with their client's unique project specifications.

Identifying and Understanding Client Specifications

The initial phase of customizing cleanroom aluminum profiles involves a thorough understanding of the client's project specifications. This process entails detailed consultations with the client to ascertain the exact dimensions, shapes, and features required for the aluminum profiles. For instance, a pharmaceutical enterprise might necessitate profiles with specialized coatings designed to resist chemical corrosion, whereas a semiconductor manufacturer might prioritize profiles engineered for easy assembly and disassembly.

The Design and Prototyping Process

Upon clarifying the client's requirements, the subsequent step involves the design of the aluminum profiles. This stage necessitates the creation of detailed drawings and specifications that align with the client's needs. Advanced design tools and software enable precise modeling of the profiles, ensuring a perfect fit within the cleanroom construction. In certain scenarios, suppliers may also produce prototypes, providing clients with the opportunity to evaluate the design before proceeding with full-scale production.

Manufacturing and Rigorous Quality Assurance

Following the finalization of the design, the aluminum profiles undergo manufacturing, utilizing high-quality extrusion processes. It is crucial that the manufacturing process remains stringently controlled to ensure the profiles meet the necessary standards for cleanliness, strength, and durability. Quality assurance represents a critical component of this phase, with comprehensive testing conducted to verify that the profiles conform to the client's specifications and the pertinent industry standards.

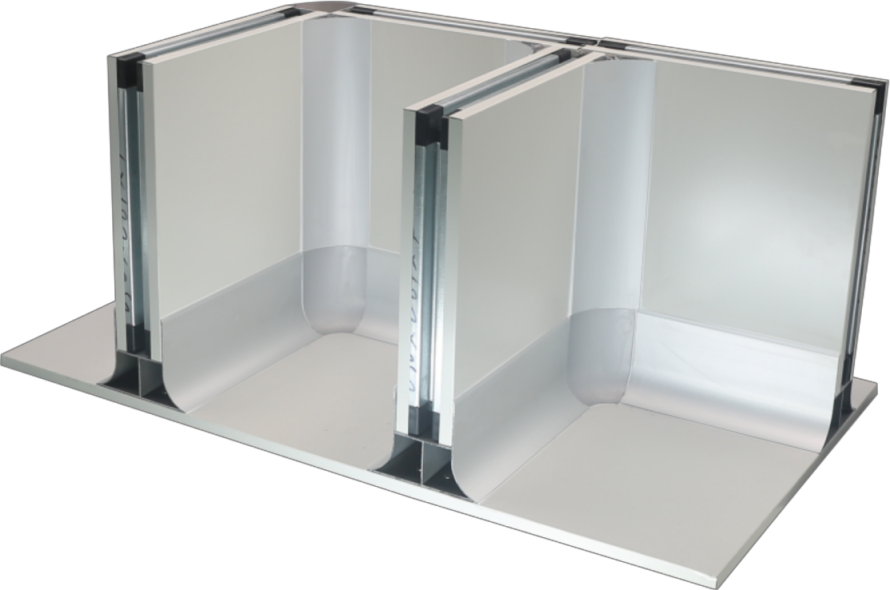

The Integral Role of Cleanroom Aluminum Profiles in Construction

Cleanroom aluminum profiles are indispensable elements in the construction of cleanrooms, providing the essential structural framework and support for walls, ceilings, doors, and windows. The design and quality of these profiles exert a direct influence on the cleanliness, durability, and overall functionality of the cleanroom environment.

Ensuring Structural Integrity and Longevity

Aluminum profiles, renowned for their strength and longevity, are ideally suited for the demanding conditions inherent in cleanroom environments. These profiles furnish the necessary structural integrity to support cleanroom panels and fixtures, ensuring the stability and security of the cleanroom over an extended period. Additionally, their inherent resistance to corrosion and wear guarantees sustained performance even in harsh conditions, such as exposure to chemicals or frequent cleaning.

Contribution to Cleanroom Cleanliness

The design of cleanroom aluminum profiles significantly contributes to the maintenance of a contamination-free environment. Smooth surfaces, minimal joints, and finishes that are easy to clean are crucial in preventing the accumulation of dust and contaminants, which is vital for upholding the sterile conditions mandated in cleanrooms. Furthermore, profiles can undergo anodization or powder coating to enhance their resistance to contamination, facilitating easier cleaning.

Versatility in Design and Application

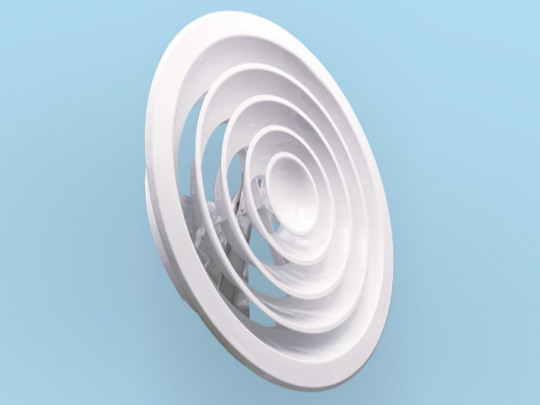

A key advantage of cleanroom aluminum profiles lies in their remarkable versatility. These profiles can be utilized to create a diverse array of cleanroom configurations, ranging from simple enclosures to intricate modular systems. This flexibility allows for the construction of cleanrooms that are precisely tailored to the specific requirements of various industries and applications. Moreover, the capacity for customization ensures seamless integration of the profiles with other cleanroom components, such as doors, windows, and HVAC systems.

Conclusion

The wholesale market for cleanroom aluminum profiles is experiencing robust growth, driven by the rising demand for contamination-free environments across multiple industries. Suppliers like E-ZONG are playing an essential role in meeting this demand by offering high-quality, customizable profiles that adhere to international standards. When participating in the wholesale distribution of cleanroom aluminum profiles, it is imperative to consider factors such as quality standards, customization possibilities, and supply chain reliability. By prioritizing these aspects, suppliers can ensure they deliver the optimal products to support the construction of cleanrooms that meet the most stringent cleanliness and functionality requirements.

In conclusion, cleanroom aluminum profiles are indispensable in cleanroom construction, providing the necessary structural integrity, cleanliness, and versatility to maintain sterile environments. Whether in pharmaceuticals, semiconductors, or other high-tech industries, these profiles are crucial to the success of cleanroom projects, ensuring that the stringent demands of these environments are effectively met.

-

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment

-

Top Aluminium Profile Manufacturers in China: Leading the Global Market

-

The Evolution of Air Tight Sliding Doors

-

AHU Aluminium Profile: A Comprehensive Guide

-

The Importance of Choosing the Right Cleanroom Door in Vietnam

-

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety

-

The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities!

-

Unlock the Possibilities with AJ Manufacturing Doors

-

Make a Statement with Manufactured Home Interior Doors!

-

what is aluminum profile? Aluminum Profiles for Your Home is the best option

-

Efficiency Meets Elegance in Industrial Cleanroom Aluminum Extrusion Solutions

-

How Aluminium Doors Are Transforming Hospital Security and Accessibility

-

What Are the Technology Behind the Hospital Double Doors

-

Double Leaf Cleanroom Door Improves Workflow Efficiency in Medical Device Assembly Lines

-

How the Right Drop Ceiling Air Vent Diffuser Cover Transforms Your Ceiling

-

How Air Vent Diffuser Ceiling Choices Impact Energy Efficiency

-

Behind the Lab Cleanroom Door: Cutting-Edge Solutions for Sterile Science Spaces

-

Customized Door Solutions That Meet Every Unique Need

-

Why Cleanroom Door Buyers Worldwide Are Turning to China's Aluminum Factories

-

Cleanroom Roll-Up Doors: Small Feature, Big Impact in Contamination Control

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.

.jpg)

Speak Your Mind