Impact of Sliding Doors Across Industries: Elevating Cleanroom Efficiency

- By:hqt

- 2024-03-15

- 29

Cleanrooms play a pivotal role in industries where maintaining hygiene and product integrity is paramount. From medical and pharmaceutical sectors to food and cosmetics manufacturing, these controlled environments ensure that stringent quality standards are met. Within these spaces, every component, including doors, plays a crucial role in upholding cleanliness and contamination control.

Introduction to the Crucial Role of Cleanrooms

1.1 Versatility and Benefits of Sliding Doors

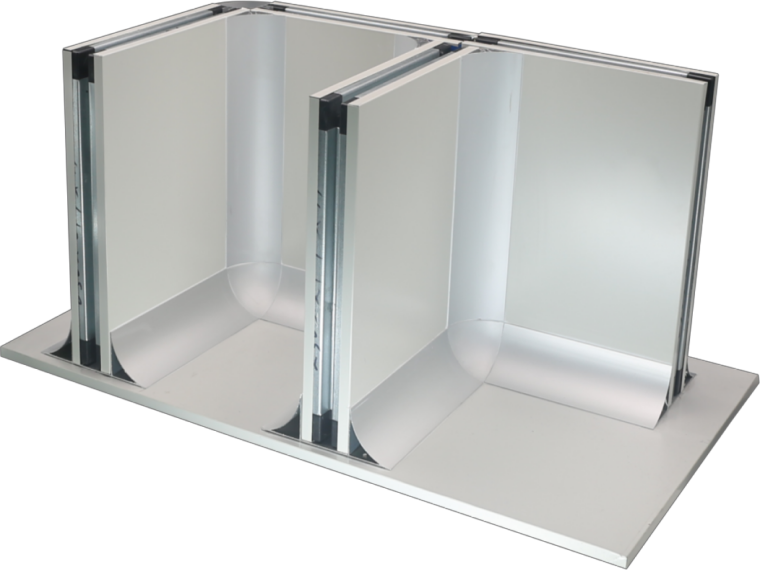

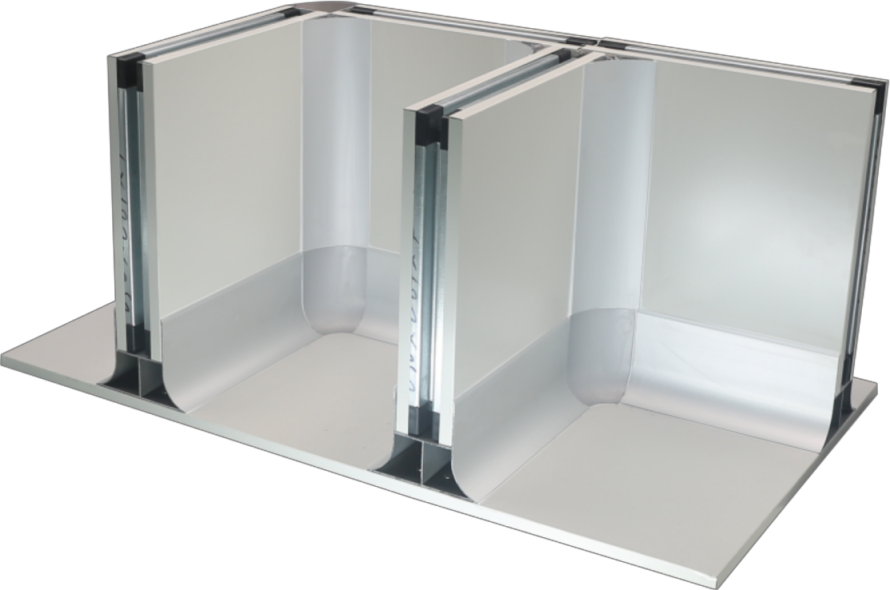

Sliding doors have emerged as indispensable components in cleanroom design, offering a multitude of benefits that enhance workflow efficiency and contamination control. Unlike traditional hinged doors, sliding doors minimize air disturbance and particle dispersion, crucial for maintaining sterile conditions. Their smooth operation and space-saving design optimize floor space utilization, facilitating seamless movement within the cleanroom environment.

1.2 Enhanced Workflow Efficiency

Sliding doors streamline the flow of personnel and equipment within cleanroom facilities, minimizing disruptions to operations. Their smooth, automated operation ensures swift access while minimizing the risk of contamination.

1.3 Contamination Control

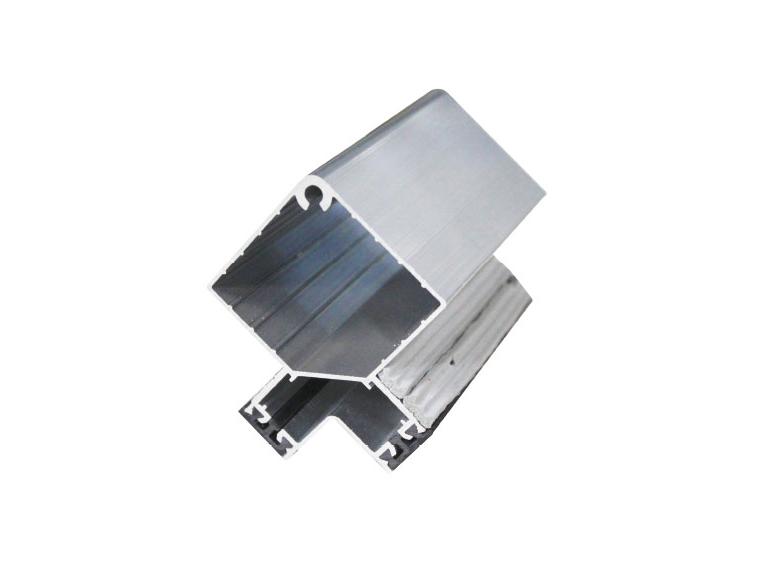

Sealed edges and precision engineering of sliding door systems prevent the ingress of contaminants, safeguarding the integrity of sensitive processes and products. Their design minimizes air leakage, maintaining the desired pressure differentials essential for contamination control.

1.4 Space Optimization

With their compact design and absence of swing space, sliding doors maximize available floor space within cleanroom facilities. This optimized layout allows for efficient equipment placement and workflow organization, enhancing overall productivity.

Industry-Specific Examples of Sliding Door Systems

Across various industries, sliding door systems have revolutionized operations within cleanroom environments. From medical device manufacturing to electronics assembly, these industries have witnessed firsthand the transformative impact of sliding doors on cleanliness, efficiency, and product quality.

2.1 Medical and Pharmaceutical

In medical and pharmaceutical cleanrooms, where sterility is non-negotiable, sliding doors provide seamless access while maintaining the integrity of critical processes. E-ZONG sliding door systems, specifically designed for cleanroom applications, ensure compliance with regulatory standards while enhancing operational efficiency.

2.2 Food and Beverage

In food and beverage manufacturing, where hygiene is paramount, sliding doors prevent cross-contamination and ensure compliance with rigorous quality standards. E-ZONG's hygienic design and robust construction make them ideal for use in cleanroom environments where cleanliness is imperative.

2.3 Electronics Manufacturing

In electronics manufacturing, where precision and contamination control are essential, sliding doors facilitate efficient movement of personnel and equipment while minimizing the risk of electrostatic discharge (ESD). E-ZONG sliding door solutions offer ESD protection and seamless integration with cleanroom automation systems, ensuring optimal performance in high-tech environments.

Precision and Purity: How Sliding Doors Ensure Compliance in Cleanroom Settings

3.1 Regulatory Standards Governing Cleanliness

In industries such as bio-pharmaceuticals and medical devices, adherence to stringent regulatory standards is paramount. Cleanroom facilities must comply with guidelines such as ISO 14644 and GMP to ensure product quality and safety.

3.2 ISO 14644 Compliance

E-ZONG sliding door systems are designed and manufactured to meet the requirements of ISO 14644, ensuring that cleanroom environments maintain the specified cleanliness levels essential for sensitive manufacturing processes.

3.3 GMP Guidelines

Compliance with Good Manufacturing Practice (GMP) guidelines is essential for industries such as pharmaceuticals, where product quality and safety are of utmost importance. E-ZONG sliding doors support GMP compliance by providing a reliable barrier against contaminants and facilitating easy cleaning and maintenance.

3.4 Seamless Compliance Audits

Sliding doors play a crucial role in facilitating seamless compliance audits by providing transparent documentation of cleanroom conditions and ensuring that regulatory requirements are met. E-ZONG's commitment to quality and compliance ensures that cleanroom facilities are audit-ready at all times, minimizing downtime and operational disruptions.

Innovative Solutions for Contamination Control: Sliding Doors in High-Tech Environments

4.1 Cutting-Edge Sliding Door Technologies

In high-tech industries such as electronics and machinery manufacturing, where precision and contamination control are paramount, sliding door systems play a crucial role in ensuring the integrity of cleanroom environments. E-ZONG, a leading supplier of cleanroom solutions, offers cutting-edge sliding door technologies tailored to the unique needs of these industries.

4.2 ESD Protection

E-ZONG sliding door systems are equipped with Electrostatic Discharge (ESD) protection features, mitigating the risk of damage to sensitive electronic components caused by electrostatic discharge. This advanced technology safeguards valuable equipment and prevents costly production delays associated with ESD-related failures.

4.3 Automated Access Control

Automated access control features streamline operations in high-tech environments by allowing seamless entry and exit of personnel and equipment. E-ZONG sliding door systems integrate with sophisticated access control systems, ensuring authorized personnel have secure access while preventing unauthorized entry, enhancing security and productivity.

4.4 Integration with Cleanroom Monitoring Systems

E-ZONG sliding door systems seamlessly integrate with cleanroom monitoring systems, providing real-time data on environmental conditions such as temperature, humidity, and particle levels. This integration allows for proactive maintenance and immediate response to deviations, ensuring optimal cleanroom performance and product quality.

Mitigating Contamination Risks and Optimizing Production Processes

E-ZONG's advanced sliding door solutions mitigate contamination risks in high-tech environments by providing a reliable barrier against airborne particles, microbes, and other contaminants. The seamless sealing mechanisms and precision engineering of E-ZONG sliding doors prevent the ingress of contaminants, safeguarding sensitive equipment and critical manufacturing processes.

5.1 Safeguarding Sensitive Equipment

Sliding door systems from E-ZONG create a controlled environment within high-tech facilities, protecting sensitive equipment from contamination and ensuring consistent performance. By maintaining cleanroom conditions, these advanced solutions extend the lifespan of valuable machinery and minimize the risk of costly repairs or replacements.

5.2 Optimizing Production Processes

The efficient operation and seamless integration of E-ZONG sliding door systems optimize production processes in high-tech environments, reducing downtime and increasing throughput. With quick access and minimal air disturbance, these advanced solutions facilitate smooth workflow transitions, enhancing overall productivity and profitability.

Hygienic Excellence: Sliding Door Systems in Food, Beverage, and Cosmetics Manufacturing

6.1 Critical Importance of Hygienic Conditions

In food, beverage, and cosmetics manufacturing, maintaining hygienic conditions is essential to ensure product quality and consumer safety. Sliding door systems play a crucial role in preventing cross-contamination and upholding stringent hygiene standards within cleanroom environments. E-ZONG offers sliding door solutions designed specifically for these industries, featuring easy-to-clean surfaces and seamless sealing mechanisms.

6.2 Preventing Cross-Contamination

E-ZONG sliding door systems with hygienic design features prevent cross-contamination between different production areas, ensuring product integrity and compliance with regulatory requirements. The smooth, non-porous surfaces of these doors are easy to clean and disinfect, minimizing the risk of microbial growth and contamination.

6.3 Elevating Product Quality and Consumer Trust

Brands in the food, beverage, and cosmetics industries have elevated their product quality and consumer trust through the implementation of E-ZONG sliding door solutions. By maintaining hygienic conditions and preventing contamination, these advanced door systems contribute to the production of safe, high-quality products that meet customer expectations.

Partnering for Success: Choosing the Right Sliding Door Supplier for Your Industry

7.1 Selecting a Reliable Supplier

Choosing the right sliding door supplier is crucial for ensuring the success and efficiency of cleanroom operations across diverse industries. E-ZONG, with its extensive experience and expertise in cleanroom solutions, is a trusted partner for businesses seeking reliable sliding door systems tailored to their specific industry needs.

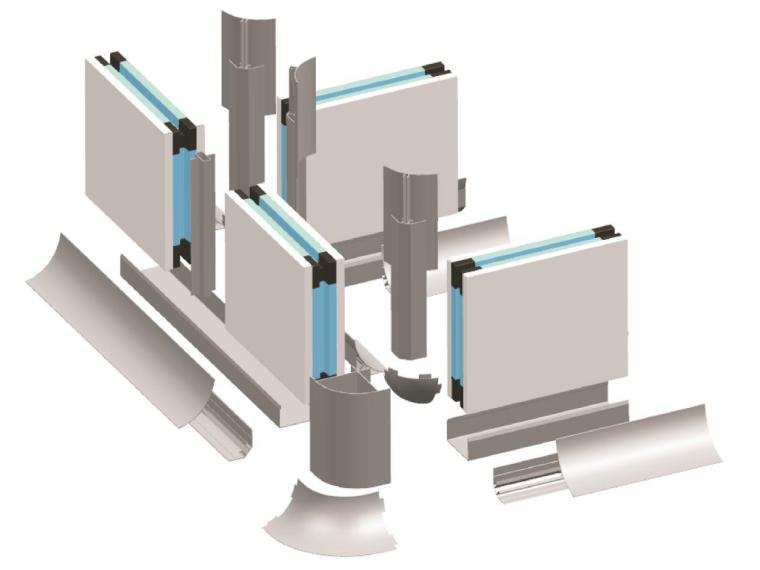

7.2 Product Customization Options

E-ZONG offers customizable sliding door solutions to meet the unique requirements of different industries and applications. From size and material options to automation features and access control systems, E-ZONG works closely with clients to design and deliver sliding door systems that align with their operational goals and facility specifications.

7.3 Industry Experience

With years of experience serving industries such as medical, pharmaceutical, food and beverage, cosmetics, electronics, and machinery manufacturing, E-ZONG understands the unique challenges and regulatory requirements of each sector. Their industry-specific expertise ensures that clients receive tailored solutions that meet the highest standards of cleanliness, compliance, and performance.

7.4 After-Sales Support

E-ZONG is committed to providing exceptional after-sales support to ensure the ongoing success and reliability of their sliding door systems. From installation and commissioning to maintenance and troubleshooting, E-ZONG's team of experts offers comprehensive support services to address any client needs or concerns promptly.

Conclusion

In conclusion, sliding door systems play a crucial role in elevating cleanroom efficiency across industries. From enhancing workflow efficiency and contamination control to ensuring compliance with regulatory standards and delivering cost-saving advantages, these doors are indispensable components of modern cleanroom facilities. As industry leaders such as E-ZONG continue to innovate and develop advanced sliding door solutions, cleanroom environments will continue to evolve, meeting the ever-increasing demands for precision, purity, and productivity.

-

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment -

Top Aluminium Profile Manufacturers in China: Leading the Global Market

Top Aluminium Profile Manufacturers in China: Leading the Global Market -

The Evolution of Air Tight Sliding Doors

The Evolution of Air Tight Sliding Doors -

AHU Aluminium Profile: A Comprehensive Guide

AHU Aluminium Profile: A Comprehensive Guide -

The Importance of Choosing the Right Cleanroom Door in Vietnam

The Importance of Choosing the Right Cleanroom Door in Vietnam -

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety -

.jpg) The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities!

The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities! -

Unlock the Possibilities with AJ Manufacturing Doors

Unlock the Possibilities with AJ Manufacturing Doors -

Make a Statement with Manufactured Home Interior Doors!

Make a Statement with Manufactured Home Interior Doors! -

what is aluminum profile? Aluminum Profiles for Your Home is the best option

what is aluminum profile? Aluminum Profiles for Your Home is the best option

-

Designing a Flexible Clean Room Aluminum Profile System

Designing a Flexible Clean Room Aluminum Profile System -

Look for in Cleanroom Aluminum Profile Wholesaler. Here to Know

Look for in Cleanroom Aluminum Profile Wholesaler. Here to Know -

HVAC Air Diffusion Products Myths Debunked: What You Really Need to Know

HVAC Air Diffusion Products Myths Debunked: What You Really Need to Know -

Why Opt Aluminum Profiles For Air Handling Units: Custom Service

Why Opt Aluminum Profiles For Air Handling Units: Custom Service -

Understanding Doors & Windows for Cleanrooms Seals Solutions:

Understanding Doors & Windows for Cleanrooms Seals Solutions: -

Options for Doors in a Cleanroom: Which Type is Right for You?

Options for Doors in a Cleanroom: Which Type is Right for You? -

6 Considerations In Choosing Clean Room Doors

6 Considerations In Choosing Clean Room Doors -

Cleanroom Doors Sliding Doors: Which Is Best for Your Facility?

Cleanroom Doors Sliding Doors: Which Is Best for Your Facility? -

Choosing the Right Hygienic Doors for Your Facility

Choosing the Right Hygienic Doors for Your Facility -

Cleanroom Aluminum Profile Wholesale Market: Key Trends and Insights

Cleanroom Aluminum Profile Wholesale Market: Key Trends and Insights

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.

Speak Your Mind