Key Requirements for Hygienic Efficient Hospital Doors

- By:Lisa

- 2022-12-28

- 29

Hygienic, safe and durable.These three dimensions can be said to be the three golden elements that must be understood in the selection of hospital doors. Among these three elements, hygiene requirements come first and become the top priority in the selection of efficient hospital doors.

Among the many hospital customers we serve, most of the buyer's questions are about the safety of the hospital door——

"How does your clean door reflect the self-cleaning and antibacterial effect?"

"What unique designs do you have that allow the door body to match the hygiene requirements of the hospital?"

"How to ensure the hygienic and clean function of the door itself in a high-concentration and high-frequency disinfection environment?"

We have been inspired in the process of continuous communication with customers, and while working hard to improve the comprehensive advantages of products, we have also summarized the design and production factors related to the hygienic performance of hospital doors. I hope you can read this article. Easily grasp the key requirements for selecting efficient sanitary hospital doors!

Clean overall design

Whether it is a conventional engineering business hospital construction or a manufacturer's door body design, there are relatively stable and uniform opening dimensions and clean door specifications. Clean door manufacturers generally design and plan the door body edge, door leaf window specification, lock body distance, hinge style and quantity selection according to the clean door specifications required for specific applications.

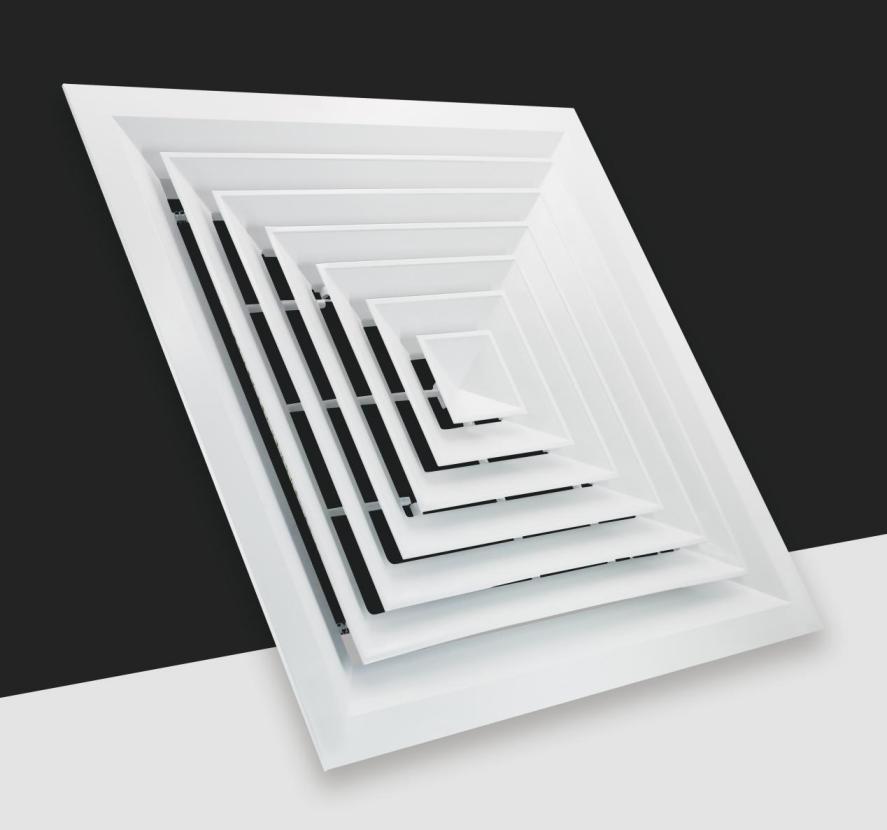

The hygienic and efficient design of the clean door can handle the transition details of the corners of the door frame and the door leaf, so that the corners, dark corners and other dead corners that are easy to hide dust and bacteria can be smoothly transitioned, reducing the difficulty of thorough cleaning of the space. According to the routine usage planning, the installation position of the window and the lock body on the door conforms to the human body structure and usage habits, reduces the contact range between the human body and the door when opening and closing the door, and reduces the risk of residual bacteria transmission caused by contact.

Use of clean door materials

In order to achieve more efficient hygiene requirements, the selection of clean door materials not only requires that the surface be bright and clean, not easy to accumulate bacteria, but also hope to have a certain self-cleaning and antibacterial effect in use. For manufacturers who produce high-end clean doors, they are more willing to use the American century-old brand Formica Compact Laminate hpl board for the door panel material. Formica hpl antibacterial board has a patent on the antibacterial effect of silver ions, which can effectively resist and snipe the bacteria on the surface of the door leaf, inhibit the survival and reproduction of bacteria, and effectively reduce the number of bacteria.

The quality of the filling inside the clean door can also greatly affect the long-term cleanliness of the door. Generally speaking, the commonly used fillers inside the door leaf are paper honeycomb, aluminum honeycomb and PU core material.

The paper honeycomb is light in weight and relatively low in cost, but it is easy to soften and mildew when exposed to water and moisture, which will not only cause the growth of bacteria inside the door leaf, but also lead to a decline in the anti-collision performance of the door body in the long run and greatly reduce its durability. In addition, the paper honeycomb has poor fire resistance, and it is extremely easy to burn in the event of an open flame, which cannot guarantee the life safety of the people inside the space.

The PU core material is relatively tough, but the disadvantage is that it will release toxic gas in the event of an open fire, which cannot achieve reserved escape time, and is very harmful to human health.

Compared with paper honeycomb and PU core material, aluminum honeycomb has better anti-collision, sound insulation, fireproof and moistureproof performance, and the fireproof grade reaches A1 level, and the comprehensive performance is excellent. It is a better clean door core material.

Use of clean door hardware

To maintain the overall efficiency and hygiene of the space, the details of the clean door hardware cannot be left behind.

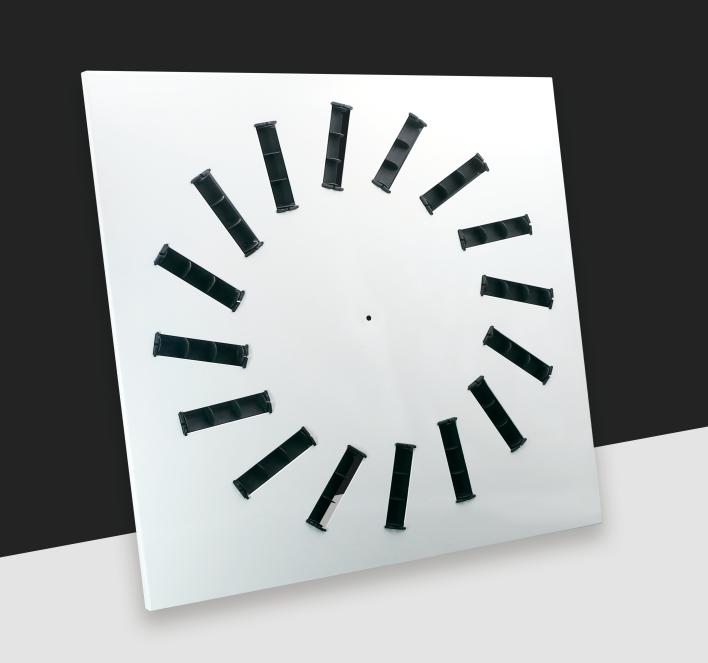

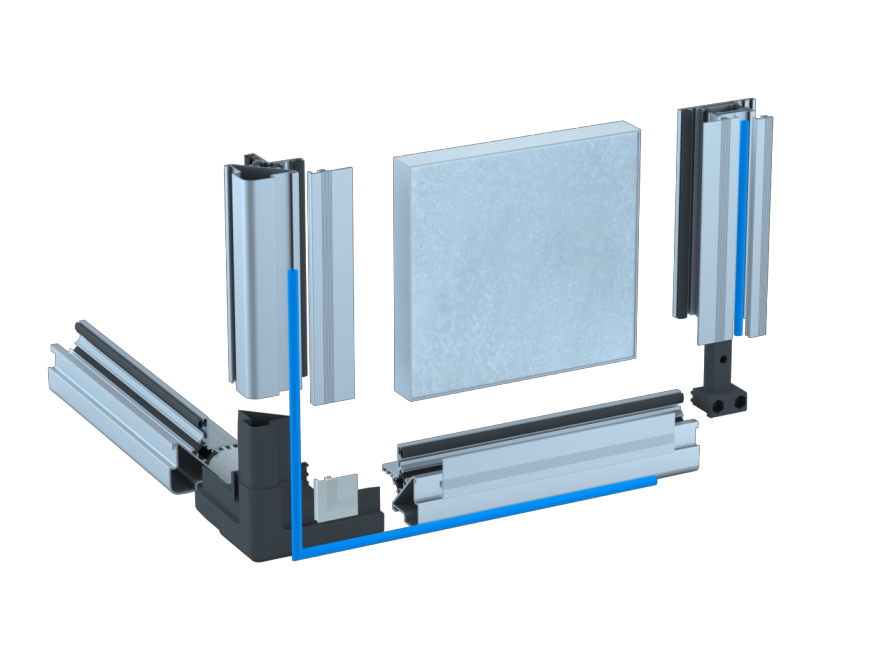

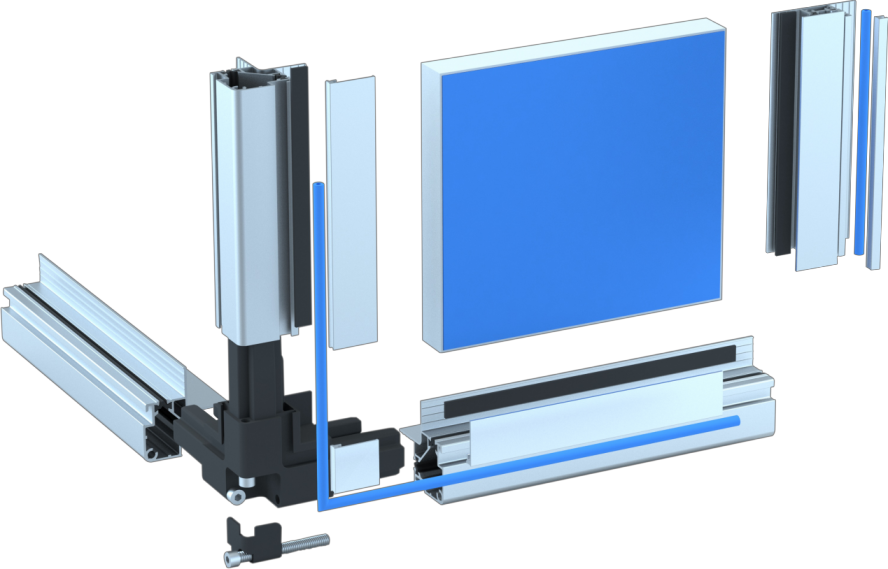

When the clean door needs to be equipped with a clean window, it is necessary to choose a double-glazed window with good sealing performance and anti-collision ability. During installation, the high-end clean door will place molecular sieves at the four corners of the double-layer glass to effectively filter the moisture that may enter the door and ensure the interior of the glass window is dry. The junction of the glass window and the door leaf is sealed and filled with 3M glue, and the surrounding areas are tightly compounded to realize the generation of sterile spots inside the glass window.

The door lock adopts high-quality 304 stainless steel split lock and handle lock, mainly arc design, the lock body has a simple structure, and no bacteria hide dead corners. And the stainless steel has high strength, can adapt to the disinfection and cleaning of high frequency and high corrosion intensity in the hospital, is more durable, and keeps it bright and clean for a long time.

Clean Door System Application

There are many functional areas in hospitals, and the types and styles of hospital doors used are relatively complex. A hygienic and clean space environment is far from being achieved by the use of only one or two clean doors. To maintain high efficiency and cleanliness, it is necessary to rely on the mutual cooperation between different clean doors to perform their own duties.

High-quality clean door manufacturers will use their rich experience to set up different types of clean doors according to different ways of using the space. According to the divided clean area, ward area, ICU area, operating room area, etc., the corresponding door type is configured to form a clean door system that is strict inside the hospital and effectively plays the role of medical and health protection.

When designing a clean door system for customers in the past, we found that the one-door-one-key transmission model would cause customers to have management confusion in the specific use process. Therefore, we can provide customers with secondary management keys in the later research and design, allowing customers to open multiple doors with one key, which not only facilitates customer management, but also provides more possibilities for the construction of clean door systems.

We combine our own design ideas and customer feedback to form the content of this article, hoping to bring you some help. If you want to consult more, please feel free to contact online customer service, E-ZONG looks forward to cooperating with you!

-

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment -

Top Aluminium Profile Manufacturers in China: Leading the Global Market

Top Aluminium Profile Manufacturers in China: Leading the Global Market -

The Evolution of Air Tight Sliding Doors

The Evolution of Air Tight Sliding Doors -

AHU Aluminium Profile: A Comprehensive Guide

AHU Aluminium Profile: A Comprehensive Guide -

The Importance of Choosing the Right Cleanroom Door in Vietnam

The Importance of Choosing the Right Cleanroom Door in Vietnam -

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety -

.jpg) The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities!

The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities! -

Unlock the Possibilities with AJ Manufacturing Doors

Unlock the Possibilities with AJ Manufacturing Doors -

Make a Statement with Manufactured Home Interior Doors!

Make a Statement with Manufactured Home Interior Doors! -

what is aluminum profile? Aluminum Profiles for Your Home is the best option

what is aluminum profile? Aluminum Profiles for Your Home is the best option

-

Guide to Doors Clean Room: Ensuring Contamination Control

Guide to Doors Clean Room: Ensuring Contamination Control -

Introducing Guangdong Clean Room Aluminum Company: E-ZONG

Introducing Guangdong Clean Room Aluminum Company: E-ZONG -

Cost-Effectiveness of Bulk Purchasing Air Diffuser

Cost-Effectiveness of Bulk Purchasing Air Diffuser -

Makeup Air Handling Unit: Here to Know

Makeup Air Handling Unit: Here to Know -

Customizing HVAC Systems Parts for Building Specific Needs

Customizing HVAC Systems Parts for Building Specific Needs -

How Return Air Diffuser Enhances HVAC Efficiency for Your Projects

How Return Air Diffuser Enhances HVAC Efficiency for Your Projects -

Exploring the Versatility of Swing Glass Door

Exploring the Versatility of Swing Glass Door -

Choosing Quality: Why Linear Diffuser Grille is Essential in Modern Design

Choosing Quality: Why Linear Diffuser Grille is Essential in Modern Design -

Introduction to Clean Room High Speed Doors: Let’s Dive into

Introduction to Clean Room High Speed Doors: Let’s Dive into -

High-Quality Clean Room Double Door for Medical and Health

High-Quality Clean Room Double Door for Medical and Health

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.

Speak Your Mind