Custom Hospital Doors Engineered for Cleanrooms & HVAC

- By:Lisa

- 2025-09-23

- 29

Why Hospital Doors Fail When Designed in a Vacuum

In modern healthcare facilities, doors are far more than partitions — they’re mission-critical components that govern airflow, enforce cleanliness, and block cross-contamination. In high-stakes zones like operating rooms, ICUs, PCR labs, and sterile processing departments, every door swing can disrupt pressure differentials — potentially pulling contaminated air into protected spaces.

If door design ignores the surrounding architecture — the wall assemblies, the HVAC airflow paths, the pressure control logic — maintaining required cleanliness becomes impossible. Patient safety hangs in the balance.

China’s Technical Code for Hospital Clean Operating Rooms (GB 50333-2013) mandates that Class I ORs must limit airborne particle recovery to ≤30% within one minute of door opening. Yet in practice, many sliding doors — due to poor seals or heavy inertia — trigger pressure swings exceeding 10Pa, effectively negating the cleanroom’s protective function.

The best hospital doors aren’t just custom-sized — they’re custom-engineered to work with your building’s systems from day one.

In radiology suites, CT rooms, and interventional labs, lead-lined doors serve as radiation shields. Their lead equivalence must be calibrated to the equipment’s energy level (typically 1.5mmPb to 4.0mmPb), while still meeting airtightness and automated operation standards — ensuring both radiation safety and infection control.

In high-traffic zones like ER corridors, outpatient lobbies, and nursing stations, HPL doors (High-Pressure Laminate) deliver the ideal balance: impact-resistant, scratch-proof, and effortless to clean — built for the daily grind of gurneys, carts, and disinfectants.

What Cleanrooms Demand from Their Doors — And Why It Matters

2.1 Airtightness: The Non-Negotiable Baseline

When closed, hospital doors in clean environments must meet ISO 14644-1 leakage thresholds — ≤0.1 m³/(h·m²) @50Pa. In negative-pressure isolation rooms or BSL-2/3 labs, that drops to ≤0.05 m³/(h·m²).

To hit these numbers, doors need dual-seal systems: EPDM compression gaskets + dynamic bottom brush seals. Frames should include sealing grooves ≥8mm deep, compressed by ≥30%, ensuring leakage increases by less than 5% after 20,000 cycles.

2.2 Surface Performance: Built for Disinfection, Designed for Safety

Doors in clinical zones endure constant wiping — often with aggressive chlorine or peroxide solutions. Surfaces must survive 5,000+ disinfection cycles without degradation.

We recommend JIS Z 2801-certified antimicrobial powder coatings, proven to eliminate ≥99.9% of Staphylococcus aureus and E. coli. For CSSD areas exposed to steam and high-pressure washdowns, anodized aluminum finishes pass 168-hour CASS corrosion tests.

In pediatric, psychiatric, or trauma zones — where impacts are routine — HPL doors can be specified with impact resistance ≥60kg·cm and scratch resistance ≥4H pencil hardness. Heat-sealed edges prevent delamination and bacterial harborage. And with woodgrain, stone, or solid-color finishes, they soften clinical environments without sacrificing performance.

2.3 Structural Intelligence: No Crevices. No Corners. No Compromises

Do hospital room doors have windows?

Most patient room doors include discreet visual monitoring windows — typically frosted or laminated safety glass (approx. 200×600mm) — so staff can observe without intrusion. But in ORs, labs, or isolation suites, doors are often solid to prevent airflow shortcuts.

All edges feature R≥5mm rounded profiles. Hinges and hardware are recessed. Door pulls are flat, protrusion-free, and support touchless activation (foot, sensor, or card) to minimize contact transmission.

In radiology zones, lead doors integrate with equipment interlocks — X-ray or fluoroscopy systems only activate once the door is fully closed and sealed. It’s a tripartite safety interlock: door position, machine status, operator clearance.

HVAC and Doors: Engineering Them to Work as One System

3.1 Door Openings Shape Airflow — Literally

In operating rooms, openings ≥1.4m wide should use dual-leaf swing designs. This minimizes disruption to vertical laminar flow during entry/exit. Maintain ≥300mm clearance between door tops and HEPA diffusers, and ≥500mm from return air grilles — any closer, and you risk short-circuiting your airflow.

Sliding door tracks? Must be fully recessed — either ceiling-suspended or wall-integrated — to preserve uninterrupted return air paths.

3.2 Pressure Interlocks: Your First Line of Defense

In ICUs or airborne infection isolation rooms, sliding doors can link directly to pressure sensors. If inter-zone pressure drops below 5Pa, the door automatically locks and sounds an alarm (visual and audible). Leave it open more than 30 seconds? The system triggers fresh air compensation.

For enterprise-level facilities, doors can communicate via BACnet protocol — feeding real-time status into your central Building Automation System.

3.3 Smart Doors: Silent Guardians of Airflow Integrity

Automatic doors are now standard — and for good reason. Multi-mode activation (foot, radar, RFID card), adjustable opening speeds (0.2–0.4m/s), and soft-close cycles ≥3 seconds prevent disruptive air bursts.

And with Modbus RTU support, they integrate seamlessly with access control, fire alarms, nurse call systems — you name it.

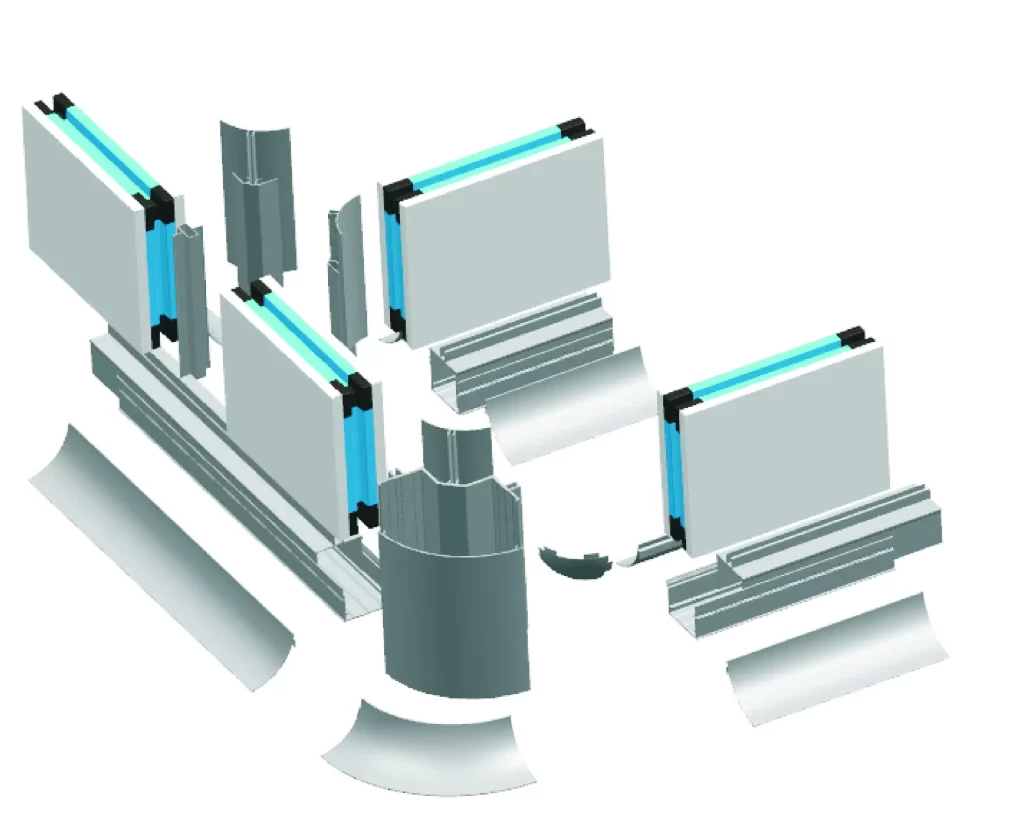

Why Aluminum Frames Are the Unsung Heroes of Hospital Door Systems

We build frames from 6063-T6 aerospace-grade aluminum — tensile strength ≥205MPa, dimensional tolerance ±0.1mm — ensuring precision fit with pre-painted steel wall panels, HVAC flanges, and modular partitions.

Internal “I-beam” reinforcements, validated by finite element analysis, limit deflection to ≤1.2mm under 0.5m/s transient pressure — beating the industry’s 3mm standard by more than half.

Choose your finish:

- Medical-grade powder coat: Alcohol- and bleach-resistant — perfect for general wards and corridors.

- Antimicrobial coating: JIS Z 2801 certified — ideal for ORs, ICUs, and isolation suites.

- Hard anodized finish: Withstands steam sterilization and 80Bar pressure washes — engineered for CSSD.

All fire-rated doors meet GB 8624 B1 flammability standards and can be upgraded with intumescent seals for 60-minute fire integrity.

HPL doors pair beautifully with aluminum frames — combining structural rigidity with surface resilience. Lead doors use a steel-lead-aluminum sandwich: anodized aluminum shell for aesthetics, embedded lead core for shielding, precision seals for airtightness.

Real-World Applications: How We Engineer Doors for Each Critical Zone

5.1 Operating Rooms: Dual-Leaf Swing + Pressure Interlock

Features laminated safety glass windows and hands-free activation (foot or motion sensor). Integrated with room pressure sensors — doors auto-lock if differential drops. Particle count recovery after 1-minute opening remains ≤25%, exceeding GB 50333 Class I requirements.

5.2 ICU / Isolation Rooms: Airlock Sliding Doors + HEPA Air Shower

Dual sliding doors operate as a pressurized airlock — rear door stays locked until front door seals. Integrated overhead air showers emit 0.3m/s HEPA-filtered air upon opening, creating a contamination barrier. Anodized surfaces withstand hydrogen peroxide vapor sterilization cycles.

5.3 Central Sterile Supply Department (CSSD): Heavy-Duty Sliding Doors

Supports loads ≥200kg. Overhead track design — zero floor grooves to trap debris. Silicone seals endure continuous 120°C heat. Anodized finish survives daily 80Bar washdowns.

5.4 PCR Labs: Negative Pressure Doors + Burst-Disc Relief

Single-leaf airtight swing door with mechanical pressure gauge window and burst-disc relief valve (activates at 50Pa) — protects structure from sudden pressure spikes. Integrates with lab BA systems for real-time alerts and audit trails.

5.5 Radiology Suites: Lead-Lined Doors + Safety Interlock

Custom lead equivalence (e.g., 2.0mmPb for CT, 3.0mmPb for angiography suites). Position sensors ensure imaging equipment only activates when door is fully sealed. Optional antimicrobial coating for hygiene compliance.

5.6 Emergency / Outpatient Lobbies: High-Impact HPL Doors

Engineered to withstand daily abuse from gurneys and stretchers. Available in woodgrain, stone, or bold solid colors — because even high-performance doors can enhance the patient experience. Aluminum frames integrate effortlessly with automatic operators and access control systems.

Your Top Questions — Answered by Our Engineering Team

Q1: What do those door signs actually mean?

They’re not just labels — they’re operational commands:

- “OR” = Operating Room

- “ICU” = Intensive Care Unit

- “P” = Patient Room

- “Biohazard” = BSL-2/3 containment zone

- “Radiation Area” = Lead shielding required

- “Fire Exit” = Emergency egress only

These signs govern access, safety protocols, and emergency response — treat them as part of your facility’s nervous system.

Q2: Do patient room doors include windows?

Yes — nearly all do. Typically frosted or laminated safety glass (~200×600mm) for discreet observation without compromising privacy. Exceptions: ORs, isolation rooms, and high-containment labs — where solid doors preserve airflow integrity.

Q3: What’s special about hospital door hardware?

Handles and pulls must be:

- Smooth, rounded, zero crevices

- Constructed from 304 stainless steel or anodized aluminum

- Support touchless activation (foot, sensor, card)

- ADA-compliant mounting height (850–1100mm) — accessible for wheelchair users and staff

Certifications That Matter: What’s Behind Our Compliance Claims

Every door system we deliver is backed by third-party validation:

- RoHS & REACH — material safety

- GB 8624 B1 — fire performance (enhanced for fire doors)

- GB/T 38698-2020 — automatic door safety

- ISO 14644-3 — airtightness (test reports available on request)

- YY 0505-2012 — EMC compliance for electrically equipped doors

- Lead doors — fully compliant with GBZ 130-2020 (Radiation Protection for Medical X-ray Equipment)

- HPL doors — certified to GB/T 7911-2013 for abrasion, chemical, and stain resistance

No checklists. No guesswork. Just documented, auditable compliance.

Closing Thought: Your Door Isn’t a Product — It’s a Patient Safety System

Choosing a hospital door isn’t about specs or price — it’s about whether that door understands the ecosystem it lives in. A great door doesn’t just open and close — it maintains pressure, blocks pathogens, integrates with your BA system, and responds to alarms.

Whether you need ultra-clean OR doors, high-cycle sliding doors, radiation-shielded lead doors, or impact-proof HPL doors — we don’t just sell doors. We engineer integrated systems: from structural design and material science to control logic and field commissioning.

Let’s Design Your Door System Together

Ready to spec the right door for your project?

Contact EZONG today for a free consultation and project-specific proposal — because in healthcare, every door should be a frontline defender of life.

-

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment -

Top Aluminium Profile Manufacturers in China: Leading the Global Market

Top Aluminium Profile Manufacturers in China: Leading the Global Market -

The Evolution of Air Tight Sliding Doors

The Evolution of Air Tight Sliding Doors -

AHU Aluminium Profile: A Comprehensive Guide

AHU Aluminium Profile: A Comprehensive Guide -

The Importance of Choosing the Right Cleanroom Door in Vietnam

The Importance of Choosing the Right Cleanroom Door in Vietnam -

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety -

.jpg) The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities!

The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities! -

Unlock the Possibilities with AJ Manufacturing Doors

Unlock the Possibilities with AJ Manufacturing Doors -

Make a Statement with Manufactured Home Interior Doors!

Make a Statement with Manufactured Home Interior Doors! -

what is aluminum profile? Aluminum Profiles for Your Home is the best option

what is aluminum profile? Aluminum Profiles for Your Home is the best option

-

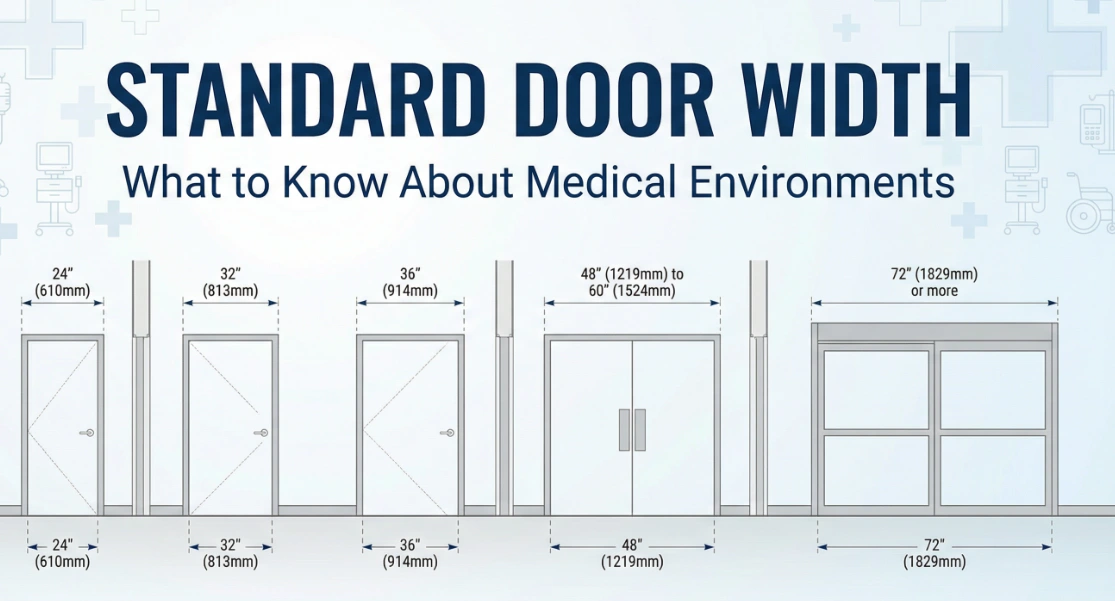

What to Know About Standard Door Width in Medical Environments

What to Know About Standard Door Width in Medical Environments -

What Is a Return Air Vent and Why Does It Matter in HVAC

What Is a Return Air Vent and Why Does It Matter in HVAC -

Top Materials for Durable Pharma Clean Room Doors

Top Materials for Durable Pharma Clean Room Doors -

Hospital Cleanroom Door Design Requirements

Hospital Cleanroom Door Design Requirements -

Swing Doors vs Standard Doors: Which Is Right for Your Facility

Swing Doors vs Standard Doors: Which Is Right for Your Facility -

Cleanroom Door Materials Explained: Key Types and Applications

Cleanroom Door Materials Explained: Key Types and Applications -

How Do Different Vent Grills Impact Medical Cleanrooms

How Do Different Vent Grills Impact Medical Cleanrooms -

Controlled Environment vs Air Clean Room Differences Explained

Controlled Environment vs Air Clean Room Differences Explained -

How to Extend the Life of Your Exterior Steel Door

How to Extend the Life of Your Exterior Steel Door -

What Are the Best Materials for AC Vent Covers

What Are the Best Materials for AC Vent Covers

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.

Speak Your Mind