Cleanroom Swing Doors Vs Standard Doors: Cost, Performance & Selection Guide

- By:Lisa

- 2025-07-29

- 29

Choosing between cleanroom swing doors and standard doors significantly impacts contamination control, air tightness, and costs in industries like pharmaceuticals and semiconductors. This guide breaks down their design, performance, and pricing, offering actionable insights for procurement professionals. Find the perfect door for your cleanroom today!

Cleanroom Swing Doors vs. Standard Doors: Key Features

Cleanroom Swing Doors

Built for high-cleanliness environments, cleanroom swing doors prioritize seamless design and contamination control.

- Design: Smooth, seamless surfaces with no joints or protrusions minimize particle buildup. A pharmaceutical facility reported an 80% drop in particle adhesion using swing doors (source).

- Materials: Constructed from stainless steel (304/316) or high-pressure laminate (HPL), these withstand disinfectants, enduring over 5,000 wipes with 70% alcohol.

- Standards: Compliant with ISO 14644-1, featuring antibacterial coatings to prevent microbial growth.

Standard Doors

Standard doors focus on versatility and aesthetics but fall short in cleanroom settings.

- Design: Panels, carvings, or joints trap dust and microbes, with lab tests showing 5–10 times higher particle adhesion than swing doors.

- Materials: Wood, MDF, or standard steel absorb moisture and degrade under disinfectants, driving up maintenance costs.

- Standards: Designed for general use, lacking optimized air tightness or contamination control.

Design and Construction Comparison

| Feature | Cleanroom Swing Doors | Standard Doors |

|---|---|---|

| Surface Continuity | Seamless, Ra < 0.8 μm, ISO 5–8 compliant | Joints and textures trap contaminants |

| Material Durability | Stainless steel/HPL, 0.01% residuals | Wood/MDF degrades with disinfectants |

| Hardware | Concealed hinges, flush handles | Exposed hinges collect dirt |

- Swing Doors: Seamless surfaces maintain ISO 6 standards, as proven in a semiconductor plant. Explore cleanroom standards.

- Standard Doors: Textured surfaces make them unsuitable for sterile environments.

Cleanroom Performance Metrics

Air Tightness

- Swing Doors: Silicone gaskets ensure leakage rates below 0.1 m³/h (EN 12207), supporting 10–50 Pa pressure differentials.

- Standard Doors: Leakage exceeds 1 m³/h, failing to maintain pressure control.

Contamination Control

- Swing Doors: Reduced particle counts from 1,000 to 200 particles/m³ in a pharmaceutical setting.

- Standard Doors: Joints promote microbial growth, unsuitable for ISO 5–8 standards.

Regulatory Compliance

- Swing Doors: Meet ISO 14644-1 and hold certifications like TÜV.

- Standard Doors: Fit for low-contamination settings like offices.

Installation and Maintenance

Installation

- Swing Doors: Require 3–5 days for precise installation, achieving 100% air-tightness in tests.

- Standard Doors: Installed in 1–2 days but lack cleanroom-grade sealing.

Maintenance

- Swing Doors: Durable materials keep costs low (~$70/year/door in hospitals).

- Standard Doors: Degradable materials and complex cleaning increase expenses.

Applications and Suitability

- Cleanroom Swing Doors: Perfect for pharmaceuticals (sterile workshops), semiconductors (wafer fabrication), and biotech labs (ISO 5–8).

- Standard Doors: Ideal for offices or commercial spaces but not cleanrooms.

Cost and Supply Chain

- Swing Doors: $700–$2,100 per door, with 30% lower total cost of ownership over 10 years. Sourced from specialized suppliers with 4–8 week lead times.

- Standard Doors: $140–$420 per door, but frequent maintenance raises costs. Available from general suppliers in 1–3 days.

How to Choose the Right Door

- Assess Cleanroom Grade: ISO 5–6 requires high air-tightness swing doors; ISO 7–8 may allow less stringent options.

- Budget Planning:

- Critical Areas: Prioritize swing doors for superior contamination control.

- Non-Critical Areas: Opt for standard doors in budget-constrained spaces like offices.

- Select Suppliers: Choose ISO-certified vendors with proven case studies.

- Verify Performance: Request air-tightness and cleanability test reports before purchasing.

Frequently Asked Questions

What are the best materials for cleanroom swing doors?

Stainless steel or HPL, compliant with ISO 14644, ensures durability and easy cleaning.

Can standard doors be adapted for cleanroom use?

Joints and moisture-prone materials make adaptation costly and ineffective. Professional swing doors are recommended.

How long do cleanroom swing doors last?

Swing doors last 15–20 years with minimal maintenance, ideal for high-cleanliness settings.

How can I ensure cleanroom compliance?

Choose ISO-certified suppliers and request air-tightness and cleanability reports.

Conclusion

Cleanroom swing doors shine in high-cleanliness industries with unmatched air tightness and durability, offering long-term savings despite higher upfront costs. Standard doors suit budget-limited, low-contamination settings. Balance cleanroom grade, environmental needs, and supplier credentials to optimize performance and cost.

-

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment -

Top Aluminium Profile Manufacturers in China: Leading the Global Market

Top Aluminium Profile Manufacturers in China: Leading the Global Market -

The Evolution of Air Tight Sliding Doors

The Evolution of Air Tight Sliding Doors -

AHU Aluminium Profile: A Comprehensive Guide

AHU Aluminium Profile: A Comprehensive Guide -

The Importance of Choosing the Right Cleanroom Door in Vietnam

The Importance of Choosing the Right Cleanroom Door in Vietnam -

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety -

.jpg) The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities!

The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities! -

Unlock the Possibilities with AJ Manufacturing Doors

Unlock the Possibilities with AJ Manufacturing Doors -

Make a Statement with Manufactured Home Interior Doors!

Make a Statement with Manufactured Home Interior Doors! -

what is aluminum profile? Aluminum Profiles for Your Home is the best option

what is aluminum profile? Aluminum Profiles for Your Home is the best option

-

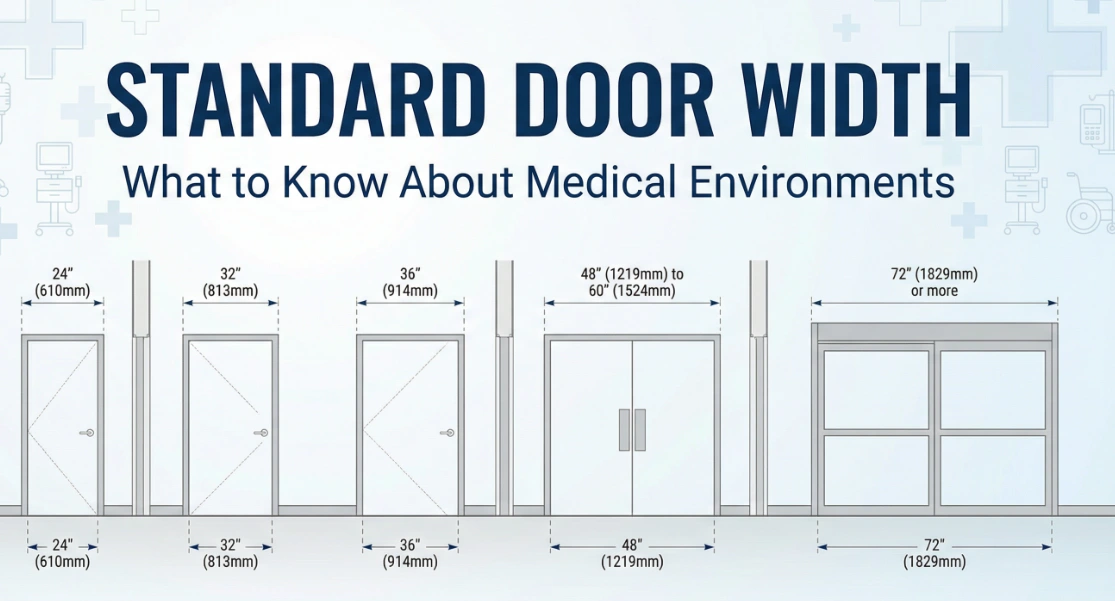

What to Know About Standard Door Width in Medical Environments

What to Know About Standard Door Width in Medical Environments -

What Is a Return Air Vent and Why Does It Matter in HVAC

What Is a Return Air Vent and Why Does It Matter in HVAC -

Top Materials for Durable Pharma Clean Room Doors

Top Materials for Durable Pharma Clean Room Doors -

Hospital Cleanroom Door Design Requirements

Hospital Cleanroom Door Design Requirements -

Swing Doors vs Standard Doors: Which Is Right for Your Facility

Swing Doors vs Standard Doors: Which Is Right for Your Facility -

Cleanroom Door Materials Explained: Key Types and Applications

Cleanroom Door Materials Explained: Key Types and Applications -

How Do Different Vent Grills Impact Medical Cleanrooms

How Do Different Vent Grills Impact Medical Cleanrooms -

Controlled Environment vs Air Clean Room Differences Explained

Controlled Environment vs Air Clean Room Differences Explained -

How to Extend the Life of Your Exterior Steel Door

How to Extend the Life of Your Exterior Steel Door -

What Are the Best Materials for AC Vent Covers

What Are the Best Materials for AC Vent Covers

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.

Speak Your Mind