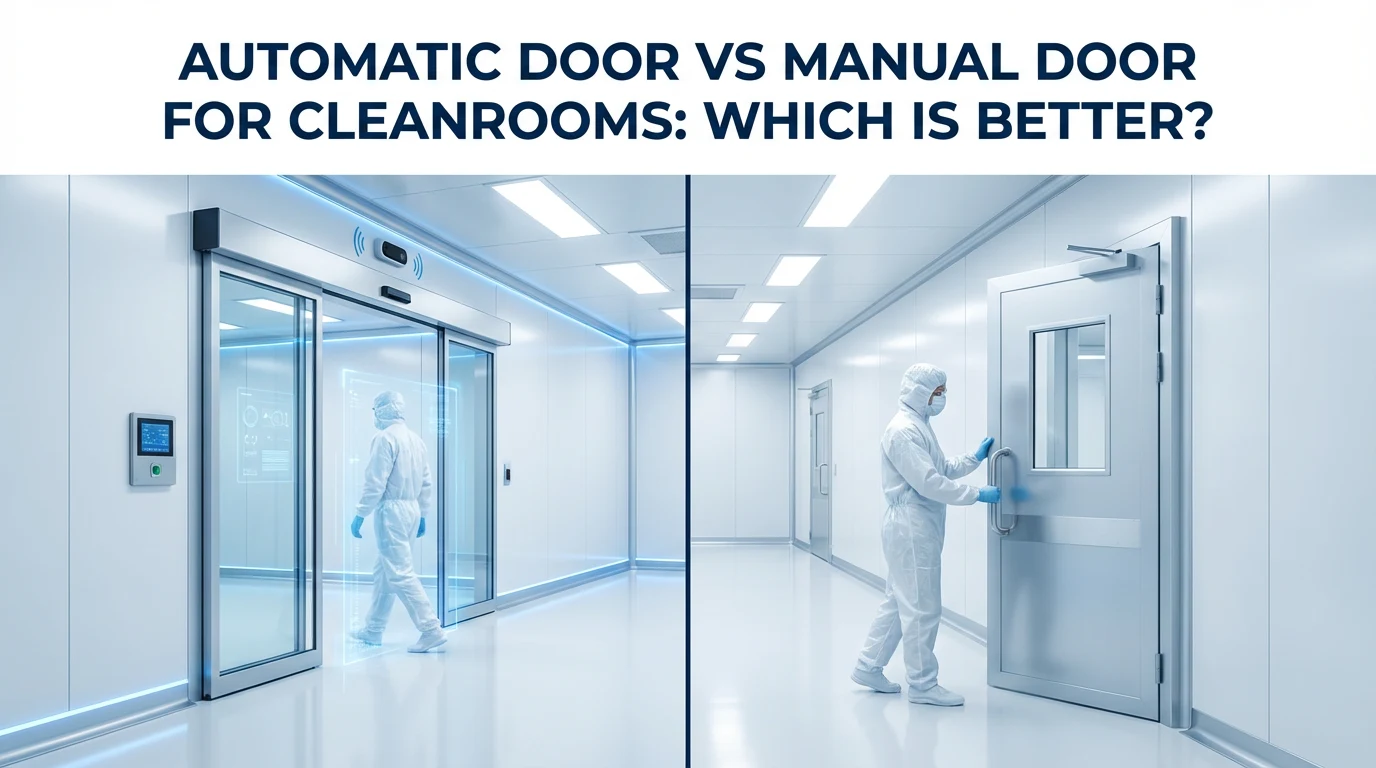

Automatic Door vs Manual Door for Cleanrooms: Which Is Better

- By:Lisa

- 2026-01-30

- 29

In the highly regulated world of cleanrooms, where even microscopic contaminants can compromise product integrity, the choice between an automatic door and a manual one is more than a mere preference—it’s a critical decision impacting contamination control, operational efficiency, and long-term costs.

Direct answer: An automatic door generally offers superior performance for modern cleanrooms due to touchless operation and better pressure control. However, manual doors remain a viable, cost-effective choice for low-traffic areas or specific emergency exits where simplicity is the priority.

Choosing the right entry system requires a deep understanding of your facility's specific needs. Whether you are managing a pharmaceutical plant, a biotech lab, or a high-tech electronics facility, the way personnel and materials move through your space dictates your success.

1. Contamination Control: The Battle of Airflow and Contact

The primary goal of any cleanroom is to keep "the bad stuff" out. When comparing an automatic door to a manual one, the first thing to look at is how they handle the risk of introducing particles or microbes.

The Power of Touchless Entry

In a sterile environment, the human hand is one of the most significant sources of contamination. Manual doors require physical contact with handles or push bars. Even with strict gloving protocols, every touch is a risk. An airtight automatic door eliminates this contact entirely. Using infrared sensors or "wave-to-open" switches, personnel can enter without touching a single surface. This touchless entry is a game-changer for maintaining ISO 5 or stricter standards, where microbial control is non-negotiable.

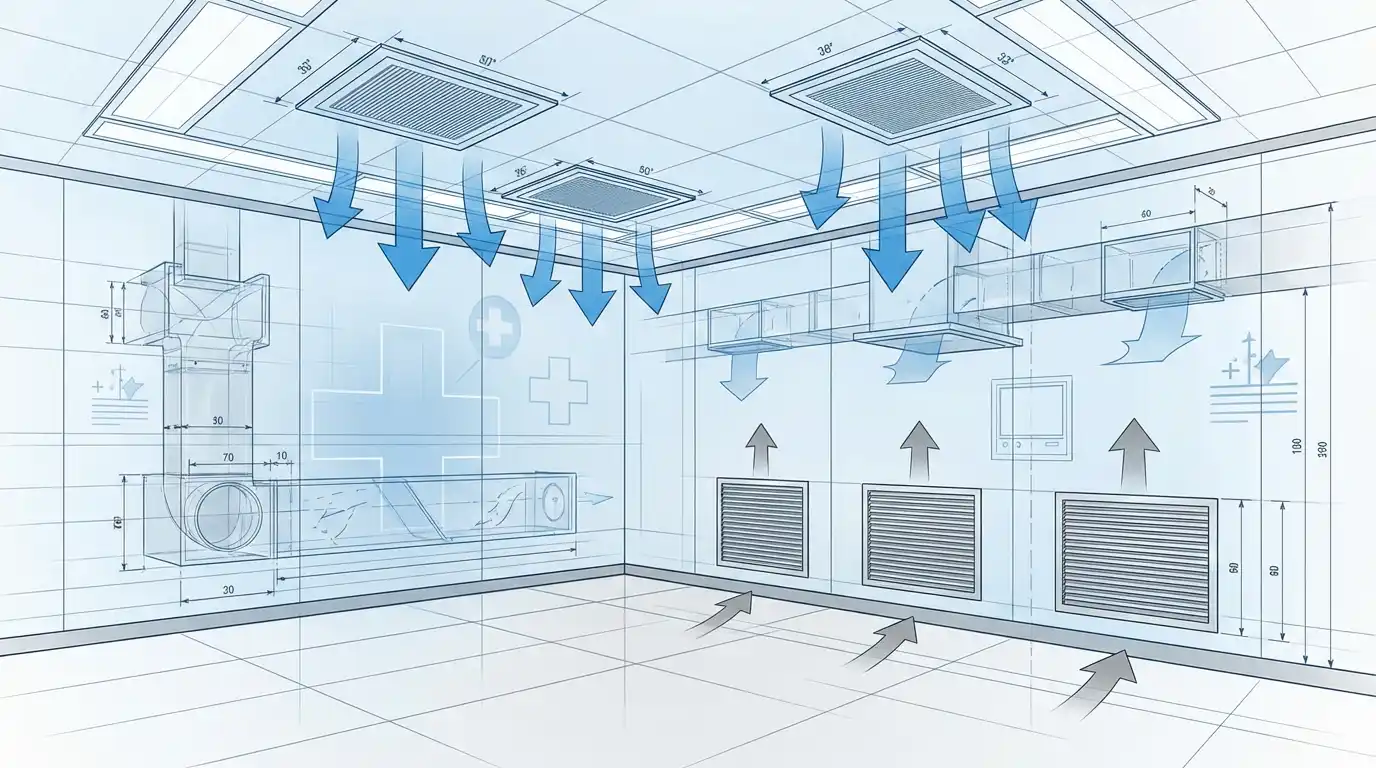

Maintaining Pressure Differentials

Cleanrooms rely on a "pressure cascade" to keep filtered air flowing from the cleanest areas to less clean ones. When a door opens, this pressure is momentarily disrupted.

- Manual Doors: These often swing open and closed at varying speeds depending on the person using them. A fast "yank" can create a vortex, pulling contaminated air into the clean zone.

- Automatic Doors: These systems move at a controlled, consistent speed. Many automatic door designs, such as sliding models, minimize the "piston effect"—the air turbulence caused by a swinging door leaf. This ensures your pressure differential stays within the required 5 to 15 Pascal variance.

Sealing Performance

A door is only as good as its seal. High-quality cleanroom doors use specialized gaskets. While both types can be built with airtight seals, an automatic door often includes a "drop seal" mechanism that engages only when the door is fully closed. This reduces wear and tear on the gasket, ensuring the automatic door remains airtight for a longer period compared to a manual door that might be left slightly ajar by a distracted worker. To understand the engineering behind these seals, you can explore how airtight doors are crucial for cleanrooms and laboratories.

2. Efficiency and Workflow: Moving at the Speed of Science

In a B2B manufacturing environment, time is literally money. If your staff has to stop, set down a tray of vials, open a door, and then pick the tray back up, you are losing seconds that add up to hours over a month.

Streamlining High-Traffic Areas

For facilities with high-traffic counts—meaning more than 30 or 40 passes per hour—an automatic door is almost mandatory. It allows for a "walk-through" workflow. Personnel wearing full personal protective equipment (PPE) often have limited visibility or dexterity. A hands-free automatic door makes their job safer and much faster.

Material Handling and Logistics

Think about material transfer. When moving large equipment or carts filled with sensitive electronics, manual doors are a nightmare. They require a second person to hold the door or involve awkward maneuvering that risks bumping into the frame. A wide sliding door or a rolling door (types of automatic door systems) can be synced with sensors to stay open just long enough for the equipment to pass, then close immediately to protect the environment.

Integration with Smart Systems

Modern cleanrooms are increasingly "smart." An automatic door can be fully integrated into your facility's Access Control System (ACS).

- Interlock Systems: You can program two automatic door units to act as an airlock, ensuring Door B cannot open until Door A is fully sealed.

- Audit Trails: Every time an automatic door opens, the system can log who entered and when, providing the digital "paper trail" required by the FDA or other regulatory bodies.

- Emergency Overrides: In the event of a fire or gas leak, these doors can be programmed to fail-open or fail-closed based on safety protocols.

3. When the Manual Door Still Wins: Budget and Simplicity

Despite the technological edge of the automatic door, the manual version is not obsolete. In fact, it is the backbone of many successful ISO 8 and ISO 9 facilities.

The Cost Factor

Let’s talk about the bottom line. The initial investment for an automatic door is significantly higher. You are paying for the motor, the sensors, the control logic, and the specialized installation. For a startup lab or a small-scale food processing plant, a manual airtight door provides the necessary containment at a fraction of the cost.

Maintenance and Reliability

A manual door is a "set it and forget it" solution. With no motors to burn out and no sensors to misalign, the maintenance schedule is minimal—usually just a quick check of the hinges and seals once a year. For remote facilities or areas with unstable power grids, a manual door offers the ultimate reliability. It will work exactly the same way during a power outage as it does during normal operation.

Specific Use Cases

Manual doors are the "best fit" for:

- Emergency Exits: Most safety codes require a manual breakout function or a dedicated manual fire door to ensure personnel can escape even if all systems fail.

- Maintenance Closets: If a door is only opened once a week for a technician to check a filter, an automatic door is overkill.

- Explosion-Proof Zones: In environments where flammable gases are present, specialized manual doors are often preferred to avoid the risk of electrical sparks from a motor (though "EX" rated automatic door options do exist at a premium).

4. Comparing the Costs

When a procurement manager looks at a quote, they often focus on the "sticker price." However, as a senior editor in this field, I always advise looking at the Total Cost of Ownership (TCO) over a five-to-ten-year period.

| Aspect | Automatic Door | Manual Door |

|---|---|---|

| Initial Purchase | High ($5k - $15k+) | Low ($1.5k - $5k) |

| Installation | Complex (Wiring & Logic) | Simple (Mechanical) |

| Energy Usage | Minimal (Standby power) | Zero |

| Maintenance | Quarterly inspections | Annual inspection |

| Contamination Risk | Very Low (Touchless) | Moderate (Hand contact) |

| Workflow ROI | High (Time savings) | Neutral |

While the manual door is cheaper on Day 1, the automatic door often pays for itself through increased throughput and a reduction in "batch failures" caused by contamination. In pharmaceutical manufacturing, a single contaminated batch can cost more than twenty automatic door installations combined. If you are struggling to decide, reviewing a guide on cleanroom swing doors vs standard doors can help clarify the performance-to-cost ratio.

5. Decision Framework: How to Choose Your System

How do you decide which one is right for your project? Use this step-by-step framework to evaluate your facility.

Step 1: Check Your ISO Classification

- ISO 1 to ISO 5: Use an automatic door. The risk of human contact and air turbulence is too high for manual options.

- ISO 6 to ISO 8: You have a choice. High-traffic paths should be an automatic door, while equipment storage can be manual.

- ISO 9 / CNC (Clean Non-Classified): Manual doors are usually sufficient.

Step 2: Analyze Traffic Patterns

Track how many people move through the entry point during a peak shift. If the count exceeds 20 people per hour, the ergonomic benefits of an automatic door will significantly boost morale and productivity. If the door is used twice a day, stick with a manual swing door.

Step 3: Material Requirements

Are you moving pallets? Use a rapid roll-up door or an automatic sliding door. Are you moving small handheld samples? A manual swing door with a vision panel (window) is fine.

Step 4: Regulatory and Safety Compliance

Does your industry (like pharma) require hands-free operation for Grade A zones? If yes, an automatic door is your only compliant option. Do you need a fire-rated door for a corridor? Check if your supplier provides a manual fire door that also meets cleanroom airtightness standards.

E-ZONG: Your Partner in Cleanroom Excellence

At E-ZONG, we don’t just sell doors; we provide entry solutions tailored to the world’s most demanding industries. Our 30,000㎡ manufacturing base utilizes advanced CNC technology to ensure every automatic door and manual door meets the exact tolerances required for ISO compliance.

Our Specialized Product Range

- The Automatic Series: Including the automatic sliding door for space-saving entry, the automatic swing door for easy retrofitting, and the rapid roll-up door for high-speed material transfer. All our automatic systems feature high-torque motors and IP54-rated electronics.

- The Manual Series: Our manual airtight door options are built with the same 304/316 cleanroom steel door frames as our automatic versions, ensuring durability and chemical resistance against harsh cleaning agents.

- Customization: From food-grade seal door gaskets for the snack industry to explosion-proof door configurations for chemical labs, we customize every unit to your size and safety requirements.

Why Choose E-ZONG

With over two decades of experience, we understand the nuances of cleanroom entry system design. We provide full documentation for your validation process, including IQ/OQ templates, ensuring your pharmaceutical cleanroom door passes every audit with flying colors. Our global service network means you get technical support when you need it, minimizing downtime and keeping your facility running at peak performance.

Conclusion

Choosing between an automatic door and a manual door isn't about finding the "best" door; it's about finding the "best fit" for your specific environment. An automatic door offers the pinnacle of contamination control and modern efficiency, making it the standard for high-tech manufacturing. Meanwhile, manual doors offer unmatched simplicity and value for secondary zones.

Don't leave your contamination control to chance. A well-planned entry strategy is the foundation of a successful cleanroom.

-

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment -

Top Aluminium Profile Manufacturers in China: Leading the Global Market

Top Aluminium Profile Manufacturers in China: Leading the Global Market -

The Evolution of Air Tight Sliding Doors

The Evolution of Air Tight Sliding Doors -

AHU Aluminium Profile: A Comprehensive Guide

AHU Aluminium Profile: A Comprehensive Guide -

The Importance of Choosing the Right Cleanroom Door in Vietnam

The Importance of Choosing the Right Cleanroom Door in Vietnam -

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety -

.jpg) The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities!

The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities! -

Unlock the Possibilities with AJ Manufacturing Doors

Unlock the Possibilities with AJ Manufacturing Doors -

Make a Statement with Manufactured Home Interior Doors!

Make a Statement with Manufactured Home Interior Doors! -

what is aluminum profile? Aluminum Profiles for Your Home is the best option

what is aluminum profile? Aluminum Profiles for Your Home is the best option

-

Automatic Door vs Manual Door for Cleanrooms: Which Is Better

Automatic Door vs Manual Door for Cleanrooms: Which Is Better -

Steel vs. Glass Sealed Door for Modern Cleanroom Needs

Steel vs. Glass Sealed Door for Modern Cleanroom Needs -

Double Swing Door vs. Single: Which Fits Your Cleanroom Needs

Double Swing Door vs. Single: Which Fits Your Cleanroom Needs -

Unit Ventilator Explained: Meeting Modern HVAC Needs

Unit Ventilator Explained: Meeting Modern HVAC Needs -

Supply vs. Return HVAC Grilles: Healthcare Selection Guide

Supply vs. Return HVAC Grilles: Healthcare Selection Guide -

Linear Diffuser: The Secret to Modern HVAC Comfort & Design

Linear Diffuser: The Secret to Modern HVAC Comfort & Design -

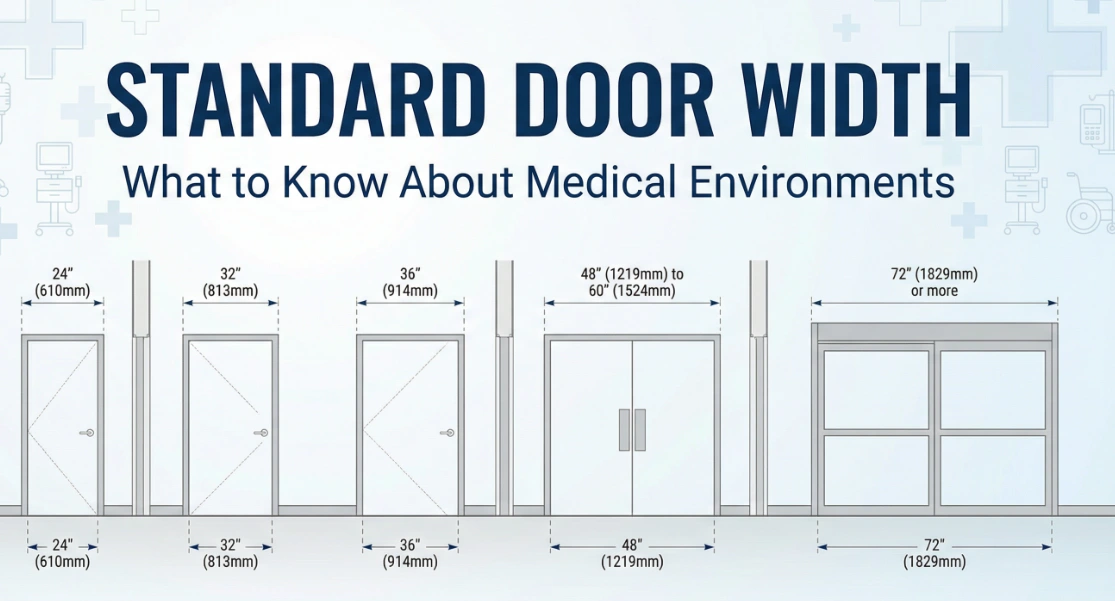

What to Know About Standard Door Width in Medical Environments

What to Know About Standard Door Width in Medical Environments -

What Is a Return Air Vent and Why Does It Matter in HVAC

What Is a Return Air Vent and Why Does It Matter in HVAC -

Top Materials for Durable Pharma Clean Room Doors

Top Materials for Durable Pharma Clean Room Doors -

Hospital Cleanroom Door Design Requirements

Hospital Cleanroom Door Design Requirements

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.

Speak Your Mind