Automatic Airtight Sliding Door: Enhancing Cleanroom Efficiency and Contamination Control

- By:hqt

- 2023-10-10

- 29

Cleanrooms play a pivotal role in diverse sectors like pharmaceuticals, semiconductor manufacturing, biotechnology, and healthcare. Stringent adherence to cleanroom standards is indispensable to safeguard product quality, research integrity, and the well-being of personnel. Nevertheless, upholding these standards presents several recurrent challenges that can jeopardize the meticulously controlled environment. An innovative remedy to confront these challenges involves the adoption of the automatic airtight sliding door.

The preservation of cleanroom standards holds paramount importance across various industries. Challenges encompassing contamination control, personnel flow management, maintenance of precise air pressure differentials, and optimization of workflow efficiency can be effectively tackled through the incorporation of automatic airtight sliding doors. These technologically advanced doors offer a pragmatic solution, enhancing cleanliness, streamlining operational processes, and safeguarding the integrity of controlled environments.

Features and Specifications of Automatic Airtight Sliding Doors

Automatic airtight sliding doors boast a comprehensive set of features and specifications meticulously designed to meet the stringent demands of cleanroom environments. Below, we delve into the key facets of these doors:

Design and Build of the Door

Automatic airtight sliding doors exhibit a slender and streamlined design, optimizing the utilization of space within the cleanroom. These doors are typically crafted from materials prized for their durability and contamination resistance. Stainless steel and other non-porous materials are commonplace choices, minimizing the potential for particle shedding and facilitating easy cleaning.

Materials Used: Durability and Contamination Resistance

Material selection for these doors is of paramount importance. They are engineered to endure the rigors of frequent operation while concurrently mitigating the risk of contaminant accumulation. These doors often employ non-corrosive, non-reactive materials, rendering them highly resistant to chemical cleaning agents.

Sliding Mechanism: Advantages over Traditional Doors

Automatic sliding doors feature a fluid and noiseless sliding mechanism, ensuring unobtrusive door operation within the cleanroom environment. In contrast to conventional swing doors, sliding doors eliminate the generation of airflow turbulence during operation, thereby contributing to the preservation of the cleanroom's precise air pressure differentials.

Seal Integrity and Air Leakage Prevention

Ensuring airtight integrity is a pivotal aspect of these doors. They are meticulously engineered to establish a steadfast seal upon closure, efficaciously preventing both air leakage and the infiltration of contaminants. To enhance sealing properties, these doors often incorporate gasket systems, magnetic seals, or air curtains into their design.

Integration with Cleanroom Control Systems

Automatic airtight sliding doors offer seamless integration into cleanroom control systems, facilitating real-time monitoring and control of door status, encompassing open, closed, or locked positions. Integration with the cleanroom's HVAC system ensures harmonious operation with the desired air pressure differentials.

Safety Features

These doors are equipped with a comprehensive suite of safety features, prioritizing the protection of personnel and the preservation of operational integrity. Motion sensors are employed to detect the presence of individuals, guaranteeing safe door operation. Additionally, emergency stop buttons and automatic obstruction detection with subsequent reversals enhance safety protocols.

How Automatic Airtight Sliding Doors Enhance Cleanroom Efficiency

Automatic airtight sliding door is integral to improving the overall efficiency of cleanroom operations. Here, we explore how these doors contribute to enhanced efficiency in cleanroom environments:

Improved Traffic Flow: Quick and Hands-Free Access

Automatic airtight sliding doors enable swift and seamless access for personnel and equipment. Their rapid response time ensures minimal waiting, reducing congestion at entry and exit points. Hands-free operation, often facilitated by motion sensors or touchless activation, minimizes the risk of contamination transfer through door handles, further streamlining the flow of personnel.

Reduced Risk of Human Error Leading to Contamination

Human error is a significant concern in cleanrooms. Manual door operation can lead to inadvertent contamination due to improper handling or failure to close doors properly. Automatic sliding doors eliminate this risk by consistently closing securely, reducing the potential for contamination incidents caused by human error.

Enhanced Pressure Differential Maintenance

Maintaining precise air pressure differentials is paramount in cleanrooms to prevent the infiltration of contaminants from outside areas. Any fluctuations in pressure can compromise the cleanroom's integrity. Automatic airtight sliding doors play a pivotal role in this regard. Their airtight mechanisms ensure a reliable seal, contributing to the consistent maintenance of the required pressure differentials.

Importance of Maintaining Consistent Pressure Levels in Cleanrooms

Cleanrooms rely on controlled air pressure levels to prevent the ingress of airborne contaminants. These pressure levels vary depending on the cleanroom classification and intended application. Consistent pressure levels are critical for product quality, research integrity, and safety in pharmaceuticals, semiconductor manufacturing, biotechnology, and healthcare.

How the Airtight Mechanism Supports This

The airtight mechanism of automatic sliding doors prevents air leakage, ensuring that the cleanroom's designated pressure levels are maintained without compromise. The doors' ability to create an effective seal contributes significantly to preserving the cleanroom environment's integrity.

Energy Savings: Reduction in Air Conditioning and Filtration Costs

Maintaining the desired temperature and air quality in cleanrooms requires significant energy expenditure, especially in HVAC systems and air filtration. Automatic airtight sliding doors help reduce energy consumption by minimizing the infiltration of outside air, resulting in lower heating, ventilation, and air conditioning (HVAC) costs.

Maintenance and Longevity: Long-Term Benefits Over Traditional Doors

Automatic sliding doors are designed for durability and require less maintenance compared to traditional swing doors. Their robust construction ensures long-term reliability. Over time, the reduced maintenance requirements and extended lifespan of automatic airtight sliding doors translate into cost savings and operational efficiency benefits.

The Role of Automatic Airtight Sliding Doors in Contamination Control

Automatic airtight sliding doors serve as a pivotal component in contamination control within cleanroom environments. Here, we delve into their role in minimizing contamination risks:

Physical Barrier: Reducing Particulate Intrusion

These doors act as a formidable physical barrier, limiting the intrusion of particulates from adjacent areas into the cleanroom. They effectively block the passage of contaminants such as dust, microbes, and airborne particles.

Reduction in Air Turbulence: How Sliding Doors Reduce the Influx of Contaminants

Automatic sliding doors are designed to operate smoothly and quietly. Unlike traditional swing doors, their sliding motion generates minimal air turbulence.

This reduced air disturbance helps maintain the controlled airflow patterns within the cleanroom, preventing the dislodgment and circulation of contaminants. As a result, cleanroom air quality is preserved.

Integration with Air Showers: Enhancing the Decontamination Process

In some cleanroom setups, automatic airtight sliding doors are integrated with air shower systems. Air showers are designed to remove surface contaminants from personnel and objects before entering the cleanroom.

The combination of these doors with air showers enhances the decontamination process. Personnel pass through the air shower before the sliding doors, further reducing the introduction of contaminants into the cleanroom.

Interaction with Personnel: Training and Practices to Maximize Contamination Control

Effective contamination control involves personnel awareness and adherence to best practices. Training programs are essential to educate cleanroom staff on the proper use of automatic sliding doors.

Practices such as waiting for the door to close completely before proceeding and avoiding contact with door surfaces help ensure that the doors fulfill their contamination control function.

CONCLUSION

The utilization of the automatic airtight sliding door represents a significant advancement in maintaining the stringent standards of cleanroom environments. These doors address common challenges such as contamination control, personnel traffic management, air pressure differential maintenance, and workflow efficiency. They do so by offering a range of features and specifications, including a streamlined design, contamination-resistant materials, smooth sliding mechanisms, impeccable sealing, integration capabilities, and comprehensive safety features.

These doors enhance cleanroom efficiency by facilitating improved traffic flow, reducing the risk of human error leading to contamination incidents, and supporting the consistent maintenance of critical pressure differentials. Maintaining precise pressure levels in cleanrooms is vital for ensuring product quality, research integrity, and personnel safety.

In summary, automatic airtight sliding doors are essential tools in the ongoing pursuit of cleanliness, safety, and operational efficiency in industries where cleanroom standards are paramount. Their contribution to contamination control and overall cleanroom performance makes them a valuable asset in a wide range of critical applications.

-

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment

-

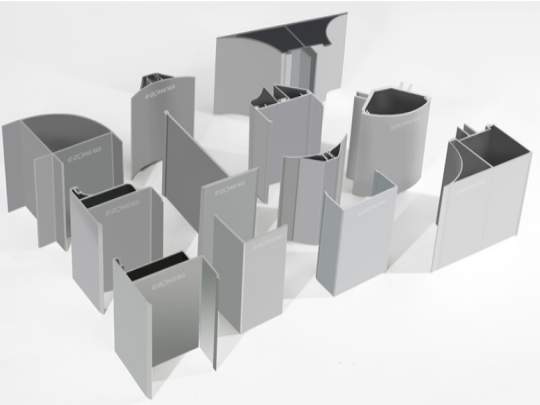

Top Aluminium Profile Manufacturers in China: Leading the Global Market

-

The Evolution of Air Tight Sliding Doors

-

AHU Aluminium Profile: A Comprehensive Guide

-

The Importance of Choosing the Right Cleanroom Door in Vietnam

-

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety

-

The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities!

-

Unlock the Possibilities with AJ Manufacturing Doors

-

Make a Statement with Manufactured Home Interior Doors!

-

what is aluminum profile? Aluminum Profiles for Your Home is the best option

-

Efficiency Meets Elegance in Industrial Cleanroom Aluminum Extrusion Solutions

-

How Aluminium Doors Are Transforming Hospital Security and Accessibility

-

What Are the Technology Behind the Hospital Double Doors

-

Double Leaf Cleanroom Door Improves Workflow Efficiency in Medical Device Assembly Lines

-

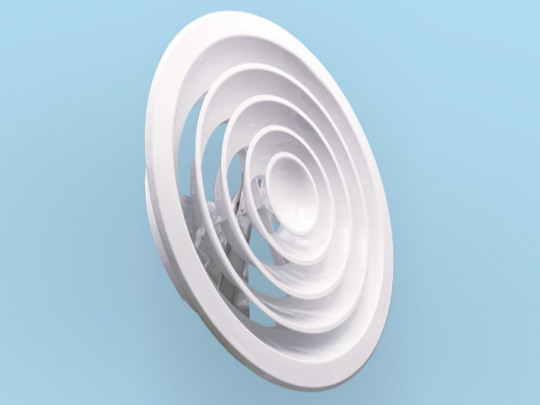

How the Right Drop Ceiling Air Vent Diffuser Cover Transforms Your Ceiling

-

How Air Vent Diffuser Ceiling Choices Impact Energy Efficiency

-

Behind the Lab Cleanroom Door: Cutting-Edge Solutions for Sterile Science Spaces

-

Customized Door Solutions That Meet Every Unique Need

-

Why Cleanroom Door Buyers Worldwide Are Turning to China's Aluminum Factories

-

Cleanroom Roll-Up Doors: Small Feature, Big Impact in Contamination Control

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.

.jpg)

Speak Your Mind