Better Aluminum For Cleanroom Process Equipment From E-ZONG

- By:hqt

- 2022-12-15

- 29

What Is The Aluminum For Cleanroom Process Equipment?

Cleanroom process equipment is equipment that is specifically designed for use in cleanroom environments. These environments are characterized by their low levels of airborne particles and are often used in industries such as pharmaceuticals, semiconductors, and biotechnology.

Cleanroom process equipment can include a wide range of items, such as air filters, HEPA filters, air showers, laminar flow cabinets, fume hoods, and contamination control systems. The main purpose of cleanroom process equipment is to maintain the cleanliness of the environment and prevent contamination of the products being processed.

"Aluminum for cleanroom process equipment" refers to the use of aluminum as a material in the construction of equipment that is specifically designed for use in cleanroom environments. In the production process, aluminum is a common material used in cleanroom process equipment.

Why Use Aluminum For Cleanroom Process Equipment?

Aluminum is a great material for use in cleanrooms. It's light and corrosion-resistant, so it's easy to maintain and clean. Aluminum equipment can also help reduce cross-contamination and decrease the risk of microbiological growth. Here are some reasons to use aluminum for cleanroom process equipment:

Corrosion-resistant:

Aluminum is a durable and corrosion-resistant material that can withstand the rigorous conditions found in cleanroom environments. This makes it a good choice for equipment that will be used in these environments over a long period.

Good conductor of heat and electricity:

Aluminum is a good conductor of heat and electricity, which makes it suitable for use in a wide range of cleanroom equipment, such as air filters, HEPA filters, and contamination control systems.

Easy-to-clean and lightweight:

Aluminum is easy to clean and maintain, which is important in maintaining the cleanliness of the cleanroom environment. It is also a relatively lightweight material, which makes it easy to handle and install in cleanroom environments.

Therefore, the use of aluminum in cleanroom process equipment is common because it offers a combination of durability, corrosion resistance, conductivity, and ease of cleaning and maintenance. These characteristics make it well-suited for use in cleanroom environments.

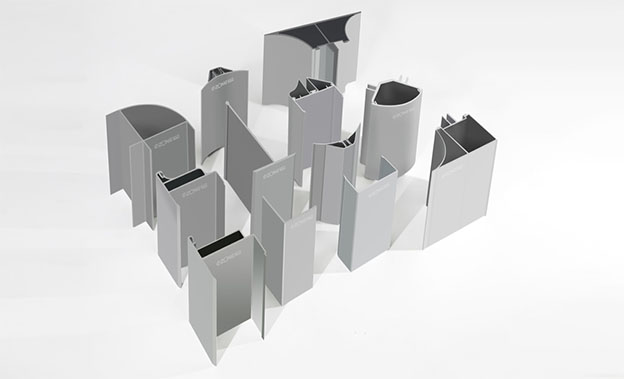

At E-ZONG, You Can Choose From Multiple Cleanroom Aluminum Profiles:

At E-ZONG, you can choose from multiple cleanroom aluminum profiles. E-ZONG is a leading company in this sector and it is known for its quality products. E-ZONG has a team of experts who provide custom solutions to customers so that they can get exactly what they want.

In its range, you will find a variety of profiles that are made with high-quality raw materials. They have been in this industry for many years now and have gained enough experience in this field to provide you with the best services at affordable rates.

Here are some of the aluminum for cleanroom process equipment they offer:

Aluminum Profile applied to the wall:

Aluminum profiles are an important component of cleanroom construction, such as the sandwich wall panels of steel modules cleanroom. Because they provide the structural support and guidance necessary for cleanroom equipment. In addition to their strength and corrosion resistance, aluminum profiles have a low thermal expansion coefficient, which makes them suitable for use in environments where temperature fluctuations are common. They are also non-magnetic, making them ideal for use in cleanrooms where sensitive electronic equipment is used.

E-ZONG offers a range of aluminum profiles designed for use in cleanroom environments, including slotted aluminum profiles, angle aluminum profiles, and inner arc column aluminum profiles. These profiles are available in a variety of sizes and shapes and can be customized to meet the specific needs of different cleanroom applications.

Aluminum Profile for windows:

Aluminum profiles for windows are typically made from high-strength, corrosion-resistant aluminum alloy. They are available in a range of shapes and sizes to suit different window designs. And they can be easily cut and drilled to fit the specific dimensions of each window. The flat contact surface of the aluminum profile allows it to be securely attached to the wall, providing stable and sturdy support for the window.

In addition to providing structural support, aluminum profiles for windows can also be used to create a sleek and modern appearance. They are often used in conjunction with other materials, such as glass or wood, to create a variety of window styles. E-ZONG offers a range of aluminum profiles specifically designed for use in window applications and can help you choose the right profile to meet the needs of your project.

Aluminum Profile for doors:

Aluminum profiles used for cleanroom doors need to be able to withstand frequent use and wear and tear. E-ZONG uses high-quality, durable aluminum alloys for their cleanroom door profiles, and subjects them to a rigorous manufacturing process that includes ingot preparation, extrusion, heat treatment, and surface treatment.

This ensures that their aluminum profiles are strong, long-lasting, and able to withstand the demands of cleanroom environments. In addition to their durability, E-ZONG's aluminum profiles for cleanroom doors are also designed to provide a smooth and reliable operation. They are available in a range of shapes and sizes to suit different door designs and can be easily customized to meet the specific needs of each project.

E-ZONG also offers a range of high-quality cleanroom doors, which can be used in combination with their aluminum profiles to create a complete cleanroom door system. If you are interested, you can also go to their official website to view more detailed information.

Add some relevant information to help me expand on the above paragraph, but don't lose the original information:

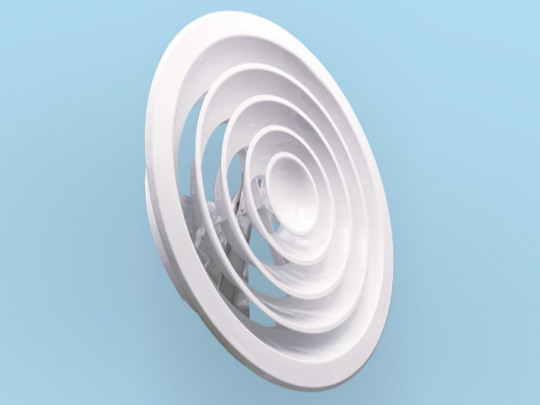

Aluminum Profile applied to the ceiling and FFU:

Aluminum profiles are commonly used in the construction of cleanroom ceilings and the support of cleanroom equipment, such as air filters and air diffusers. They offer a strong and lightweight support structure that can be easily customized to fit the specific dimensions and requirements of each project.

E-ZONG's aluminum profiles for cleanroom ceilings and FFU support are made from high-quality, corrosion-resistant aluminum alloys, and are subjected to a rigorous manufacturing process to ensure their durability and longevity.

In addition, their surface treatment and coating processes help to protect the aluminum from damage and wear and enhance its overall performance in cleanroom environments. E-ZONG offers a range of aluminum profiles for cleanroom ceilings and FFU support and can provide expert assistance in selecting the right profiles for your project.

Final Word:

Depending on the design of the cleanroom, the aluminum profile may need to be extruded into a specific shape to fit the walls of the cleanroom and provide the necessary support and structure. Additionally, the aluminum profile may need to be coated or treated to provide additional resistance to corrosion and other environmental factors.

E-ZONG will also provide you with professional deep processing, various surface treatment methods, and other services. Choosing E-ZONG is equivalent to choosing a reliable partner.

-

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment

-

Top Aluminium Profile Manufacturers in China: Leading the Global Market

-

The Evolution of Air Tight Sliding Doors

-

AHU Aluminium Profile: A Comprehensive Guide

-

The Importance of Choosing the Right Cleanroom Door in Vietnam

-

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety

-

The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities!

-

Unlock the Possibilities with AJ Manufacturing Doors

-

Make a Statement with Manufactured Home Interior Doors!

-

what is aluminum profile? Aluminum Profiles for Your Home is the best option

-

High Speed Clean Room Doors Cut Contamination Risk

-

Dustproof Cleanroom Door Innovation for Sterile Spaces

-

How Cleanroom Half Glass Swing Door Enhances Sterile Access

-

Why Custom Cleanroom Aluminum Profile Matters Today

-

Smart Ceiling Air Diffuser: Dampers Add Full Control

-

E-ZONG: Trusted Air Tight Sliding Cleanroom Door Manufacturer

-

Top Benefits of Clean Room Roll Up Door Systems

-

Cleanroom Glass Door Innovations You Should Know

-

Improve Airflow With the Right Air Diffuser Vent

-

Why Every Laboratory Needs a Sealed Cleanroom Door

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.

.jpg)

Speak Your Mind