Unit Ventilator Explained: Meeting Modern HVAC Needs

- By:Lisa

- 2026-01-21

- 29

In the past, heating and cooling were often seen as a "whole-building" problem. If the lobby was cold, the heater went on for everyone. Today, we know better. Modern architecture focuses on "zone control"—the idea that every room has its own unique needs. A sunny office needs different treatment than a windowless laboratory. This is exactly where the unit ventilator shines, offering a tailored approach to air quality that balances energy savings with human wellness.

Have you ever walked into a crowded classroom or a busy medical facility and wondered how the air stays so fresh and the temperature remains perfectly balanced despite the room being full of people? More often than not, the silent hero behind that invisible comfort is the unit ventilator, a sophisticated piece of technology designed to ensure we breathe clean air while staying focused, healthy, and comfortable.

1. Fundamentals: More Than Just a "Fan in a Box"

To the untrained eye, a unit ventilator might look like a simple metal cabinet sitting under a window or perhaps tucked neatly into a ceiling. However, describing it as just a "fan in a box" is like calling a modern smartphone just a "portable phone." It understates the incredible engineering happening inside that maintains our indoor climate.

What Exactly Is a Unit Ventilator

At its heart, a unit ventilator is a self-contained heating, ventilation, and air conditioning system. Its primary mission is to provide conditioning—heating, cooling, and, most importantly, fresh air—to a specific, individual zone. Unlike a massive central furnace or a giant air handling unit (AHU) that blows air through miles of dusty ductwork, this system lives right where the action is: in the room with you.

The Choice: Distributed vs. Centralized Systems

When planning a new building or renovating an old one, choosing a unit ventilator represents a "distributed" approach, which offers distinct advantages over a centralized air handling unit (AHU):

- Precision Control: Every room is its own master. If the sun hits one side of the building, those units can cool while the shaded side stays warm.

- Energy Savings: You avoid the "transportation tax" of air. In central systems, fans must push air through hundreds of feet of ductwork, losing energy and temperature along the way.

- Safety and Isolation: If a unit in one room needs service, the rest of the building functions perfectly. It also prevents the cross-contamination of air between different rooms.

- Instant Response: Because the machine is in the room, it detects air quality needs immediately, rather than waiting for a sensor hundreds of feet away to react.

2. Why Modern Buildings Demand Localized Solutions

Several global shifts have pushed the unit ventilator to the forefront of building design. It isn’t just about comfort anymore; it’s about safety, health compliance, and long-term sustainability.

The Indoor Air Quality Revolution

We now understand that high levels of carbon dioxide and stagnant air can lead to "sick building syndrome." Modern units address this through three primary layers of defense:

- High-efficiency filters: To catch dust, pollen, and microscopic particles.

- Fresh air dampers: That automatically open to bring in outdoor oxygen.

- Smart sensors: That detect when a room is too "stuffy" and increase airflow.

When children are in a classroom, their ability to concentrate is directly linked to the air quality. A unit ventilator ensures that the "brain fog" associated with poorly ventilated rooms is a thing of the past by providing a constant replenishment of oxygen.

3. A Technical Deep Dive: Inside the Machine

A professional-grade system is a symphony of several high-performance components working in perfect harmony.

Core Engineering Components

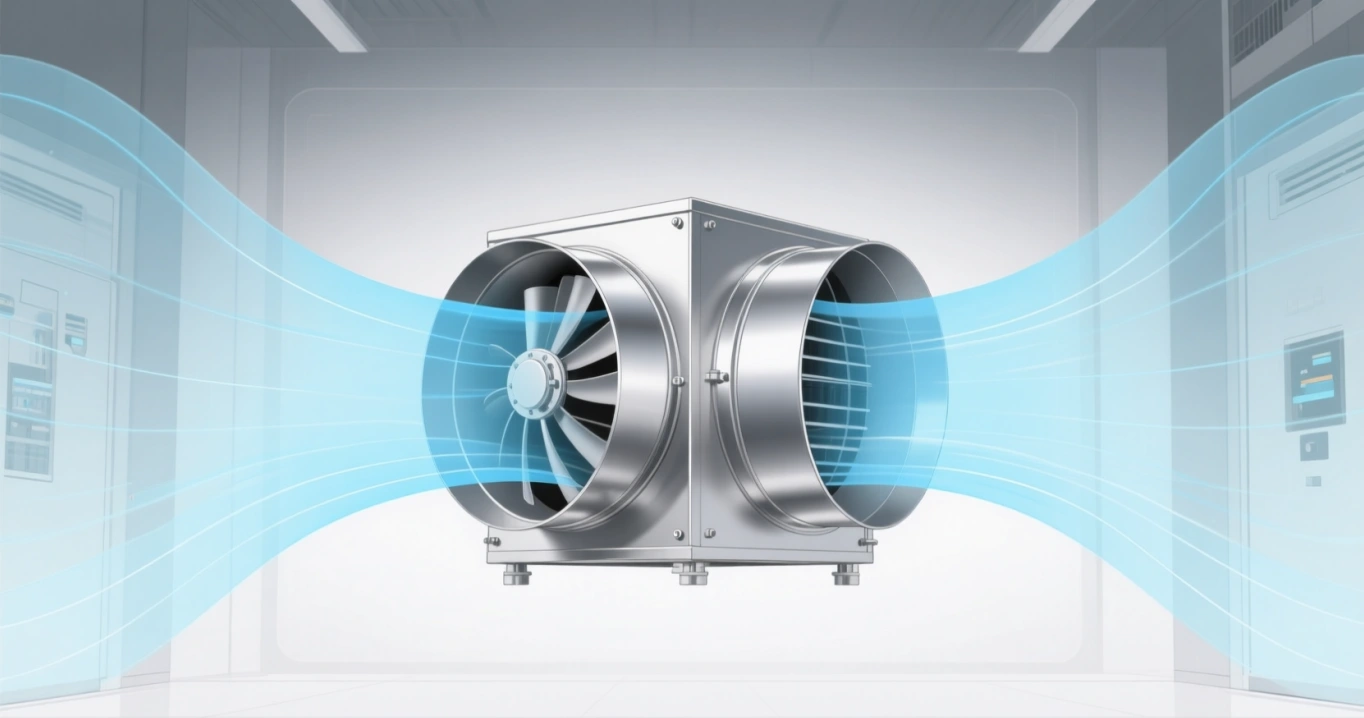

- The Fan Section (The Heartbeat): Uses high-efficiency, variable-speed fans that whisper at low speeds, ensuring the machine does its job without being a distraction in libraries or classrooms.

- Multi-Stage Air Filtration (The Shield): Before air reaches your lungs, it passes through a pre-filter, a primary filter, and often a HEPA filter in medical settings to capture 99.99% of microscopic particles.

- The Heat Exchange Coils (The Muscles): These feature aluminum fins bonded to copper tubes, often treated with anti-corrosion coatings to prevent mold growth.

- The Frame (The Skeleton): Professional manufacturers use aluminum profiles and aluminum extrusions to provide a rigid, rust-proof structure that prevents rattles and air leaks.

Why Premium Materials Like Aluminum Rule

The frame and casing are critical performance factors. A flimsy frame made of cheap materials will vibrate and eventually develop air leaks.

- Corrosion Resistance: Unlike steel, aluminum remains pristine and strong even in humid environments.

- Structural Integrity: It maintains airtight performance under the constant pressure of airflow.

- Thermal Protection: High-end aluminum profiles can include "thermal breaks" to prevent condensation from forming on the outside of the unit, protecting your walls and floors.

4. Intelligent Adaptation: Operating Modes

A unit ventilator doesn't just "blow air"; it thinks. Through a series of internal dampers and sensors, it chooses the most efficient way to achieve the desired climate.

| Operating Mode | Primary Action | Targeted Benefit |

|---|---|---|

| Ventilation Mode | Opens outdoor dampers for 100% fresh air intake. | Lowers CO2 and replenishes oxygen for mental clarity. |

| Thermal Adjustment | Circulates air over internal heating or cooling coils. | Rapid, localized temperature control per individual room. |

| Economizer Mode | Draws in cool outside air for "free cooling." | Slashes energy costs by up to 50% in spring and fall. |

| Dehumidification | Slows airflow over cold coils to wring out moisture. | Prevents mold and improves "perceived" comfort. |

5. The Cleanroom Connection: When "Clean" Isn't Enough

In high-tech manufacturing and healthcare, the unit ventilator is part of a much larger ecosystem. When designing a cleanroom, the unit must work in harmony with the building's structure to maintain ISO standards.

Integration with Specialized Doors

A unit ventilator often creates positive pressure in a room to keep dust out. However, that pressure is useless if the room has "leaky" doors. This is where airtight doors and medical automatic doors become vital.

By using a cleanroom door designed for a hermetic seal, the HVAC system can maintain stable pressurization with much less effort. In a busy hospital, an automatic sliding door equipped with high-quality seals ensures that the environment remains protected even with high foot traffic. These doors can be linked to the unit's logic; when the automatic door opens, the unit adjusts to compensate.

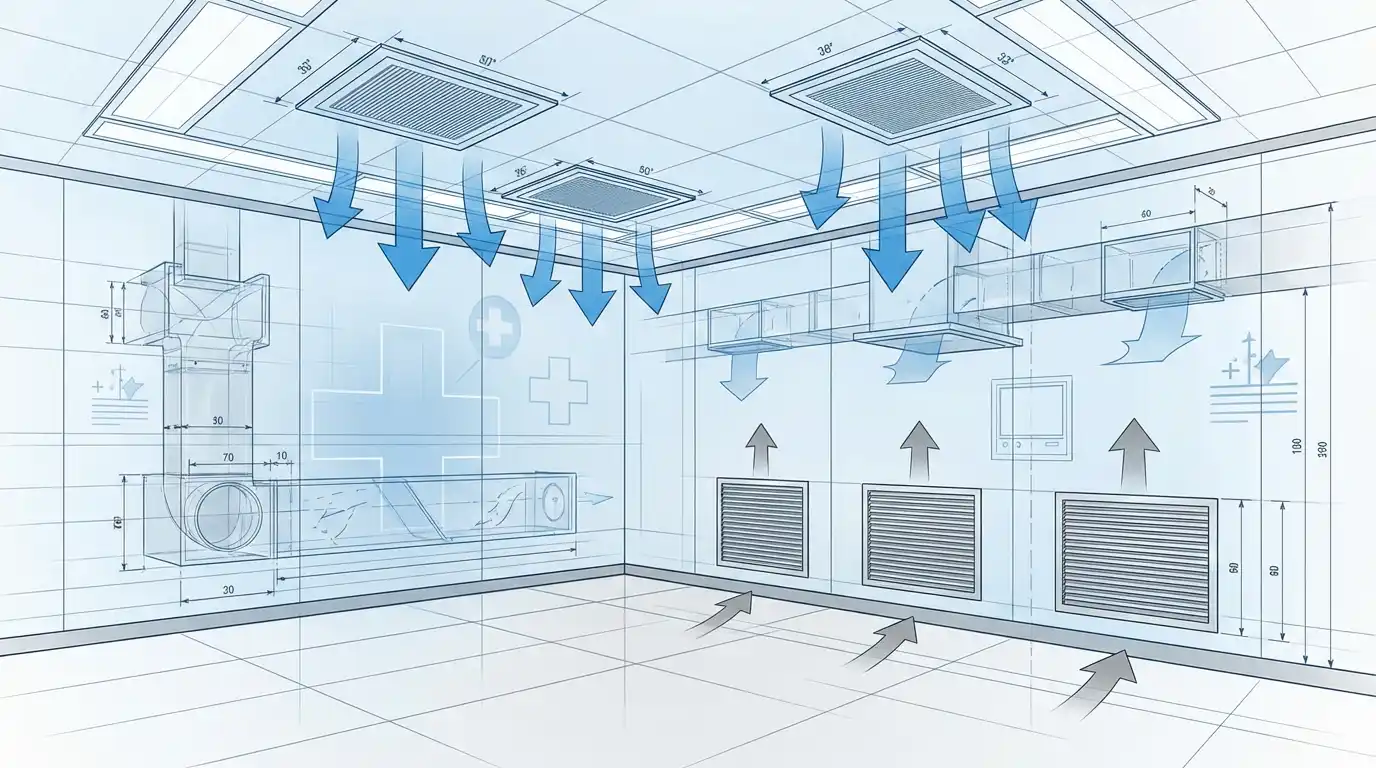

Laminar Flow and Air Distribution

In sensitive areas, an air diffuser is used to create laminar flow—a smooth stream of air that sweeps particles toward the floor. Manufacturers like E-ZONG excel here by providing specialized air diffuser profiles that minimize turbulence and eliminate "dead zones" where bacteria might settle.

6. Comparing Options: Making the Right Choice

- Unit Ventilator vs. Fan Coil Unit (FCU): The biggest difference is fresh air. A fan coil unit mostly recirculates indoor air. A unit ventilator handles both temperature and fresh outdoor air intake, making it far superior for high-occupancy spaces.

- Unit Ventilator vs. PTAC (Packaged Terminal Air Conditioner): Standard wall units like PTACs (often found in hotels) are often loud and have short lifespans. A professional unit ventilator is a long-term investment designed for 20-25 years of service with much lower noise levels and better control through a BAS (Building Automation System).

7. B2B Buying Guide: What Professionals Need to Know

Purchasing HVAC equipment for a large-scale project is a significant decision. You are buying the air quality for the next two decades.

- Sizing and Capacity: Don't just buy the biggest unit. An oversized unit will "short-cycle," wearing out the motor and failing to remove humidity.

- Total Cost of Ownership: Higher energy efficiency pays for itself. Check if filters can be changed in seconds and if coils are easy to reach.

- Component Quality: Ensure the frames use high-grade aluminum profiles and check if the automatic doors in the facility interface with the system to save energy.

- Compliance: Look for products vetted by international testing laboratories to ensure they deliver the air quality promised, especially for medical or lab settings.

Precision Excellence for Modern Facilities

The unit ventilator may not be the most glamorous part of a building's design, but it is certainly one of the most critical. By integrating specialized components—from HEPA filters to high-grade aluminum extrusions—you create an environment where technology and comfort coexist. In sensitive medical or pharmaceutical settings, pairing these systems with cleanroom doors and medical automatic doors from specialized partners like E-ZONG ensures that air quality and pressure are never compromised.

If you are ready to see how precision engineering can transform your building’s air quality, explore the latest in professional cleanroom and HVAC components today.

-

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment -

Top Aluminium Profile Manufacturers in China: Leading the Global Market

Top Aluminium Profile Manufacturers in China: Leading the Global Market -

The Evolution of Air Tight Sliding Doors

The Evolution of Air Tight Sliding Doors -

AHU Aluminium Profile: A Comprehensive Guide

AHU Aluminium Profile: A Comprehensive Guide -

The Importance of Choosing the Right Cleanroom Door in Vietnam

The Importance of Choosing the Right Cleanroom Door in Vietnam -

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety -

.jpg) The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities!

The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities! -

Unlock the Possibilities with AJ Manufacturing Doors

Unlock the Possibilities with AJ Manufacturing Doors -

Make a Statement with Manufactured Home Interior Doors!

Make a Statement with Manufactured Home Interior Doors! -

what is aluminum profile? Aluminum Profiles for Your Home is the best option

what is aluminum profile? Aluminum Profiles for Your Home is the best option

-

Double Swing Door vs. Single: Which Fits Your Cleanroom Needs

Double Swing Door vs. Single: Which Fits Your Cleanroom Needs -

Unit Ventilator Explained: Meeting Modern HVAC Needs

Unit Ventilator Explained: Meeting Modern HVAC Needs -

Supply vs. Return HVAC Grilles: Healthcare Selection Guide

Supply vs. Return HVAC Grilles: Healthcare Selection Guide -

Linear Diffuser: The Secret to Modern HVAC Comfort & Design

Linear Diffuser: The Secret to Modern HVAC Comfort & Design -

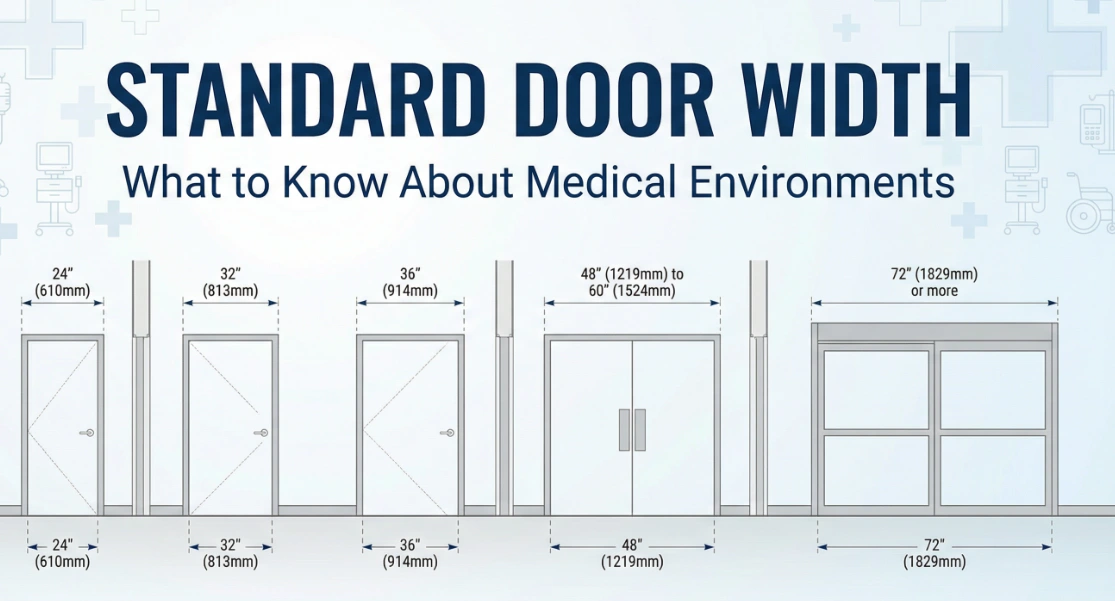

What to Know About Standard Door Width in Medical Environments

What to Know About Standard Door Width in Medical Environments -

What Is a Return Air Vent and Why Does It Matter in HVAC

What Is a Return Air Vent and Why Does It Matter in HVAC -

Top Materials for Durable Pharma Clean Room Doors

Top Materials for Durable Pharma Clean Room Doors -

Hospital Cleanroom Door Design Requirements

Hospital Cleanroom Door Design Requirements -

Swing Doors vs Standard Doors: Which Is Right for Your Facility

Swing Doors vs Standard Doors: Which Is Right for Your Facility -

Cleanroom Door Materials Explained: Key Types and Applications

Cleanroom Door Materials Explained: Key Types and Applications

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.

Speak Your Mind