Steel vs. Glass Sealed Door for Modern Cleanroom Needs

- By:Lisa

- 2026-01-27

- 29

In the precision-driven world of modern cleanrooms, the sealed door acts as the silent guardian of your controlled environment. Whether you are managing a pharmaceutical lab, a semiconductor fab, or a biotech research center, the entry point is often the most vulnerable spot for contamination. Selecting the right barrier isn't just about closing a gap; it’s about maintaining a delicate pressure balance and ensuring operational efficiency for years to come.

For most high-standard cleanrooms, particularly those classified under ISO Class 5 through 8, steel sealed door systems have long been the gold standard. They offer a level of rugged reliability and cost-effectiveness that is hard to beat in high-traffic industrial zones. However, as cleanroom design evolves to prioritize transparency and employee well-being, the glass sealed door has carved out a vital niche, offering irreplaceable visual access in monitoring zones and collaborative workspaces.

This comprehensive guide will dive deep into the technical and practical nuances of steel versus glass, empowering you to make a data-backed decision for your facility.

The Critical Role of a Sealed Door in Modern Facilities

Before we compare materials, we must understand what we are asking these doors to do. A cleanroom door is not a standard piece of hardware; it is a precision-engineered component of the HVAC and filtration system.

The Frontline of Contamination Control

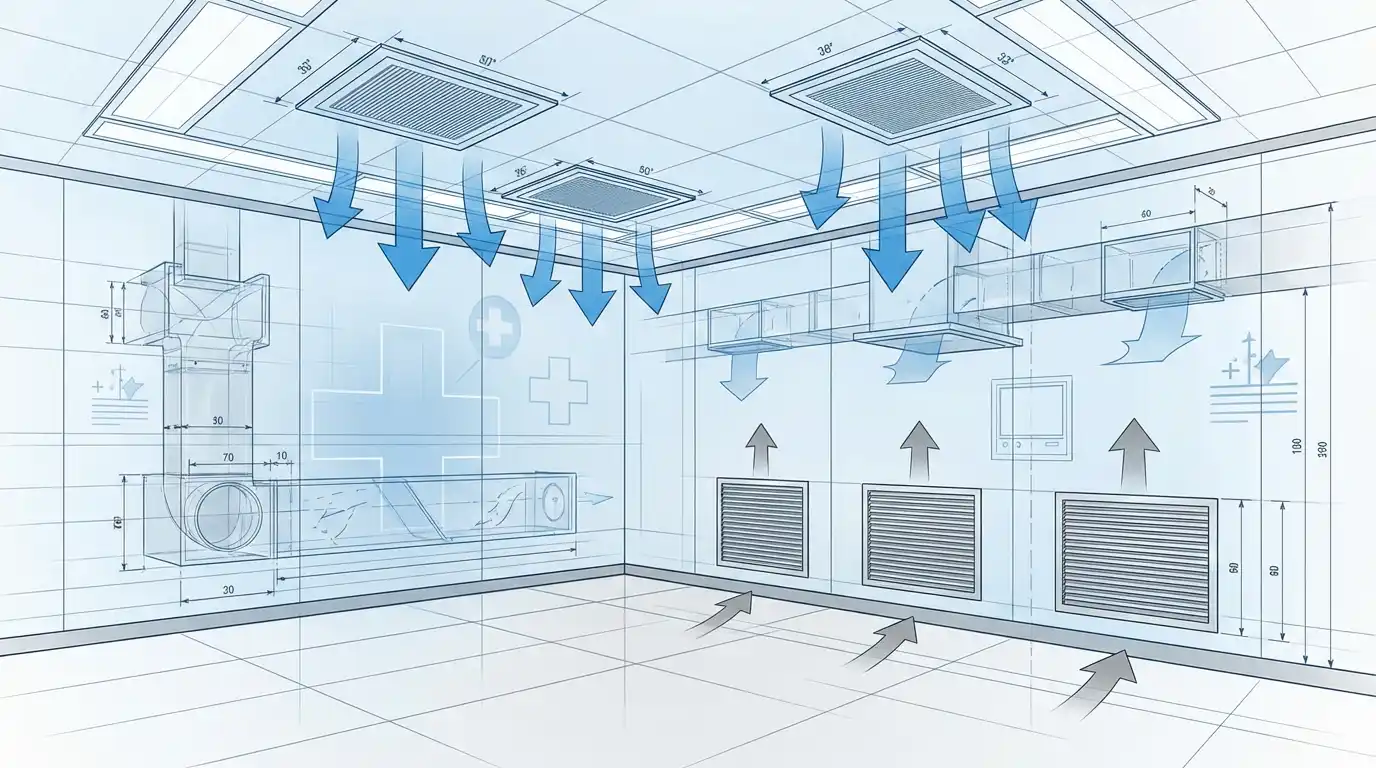

In an ISO-certified environment, the sealed door serves as the primary barrier against airborne particulates. A high-quality metal door or glass portal must integrate seamlessly with your wall panels to eliminate any "dead zones" where bacteria or dust can hide. This is where the concept of a "flush-mounted" design becomes essential. By ensuring the door leaf and frame are on the same plane, you minimize turbulence in the airflow and make sterilization significantly easier.

In biopharmaceutical settings, where microbial growth is the enemy, the surface finish of your entry door is paramount. Specialists look for a roughness average (Ra) of less than 0.8 micrometers. This ultra-smooth surface ensures that disinfectants can reach every nook and cranny during the cleaning cycle.

Pressure Differential and Airtightness

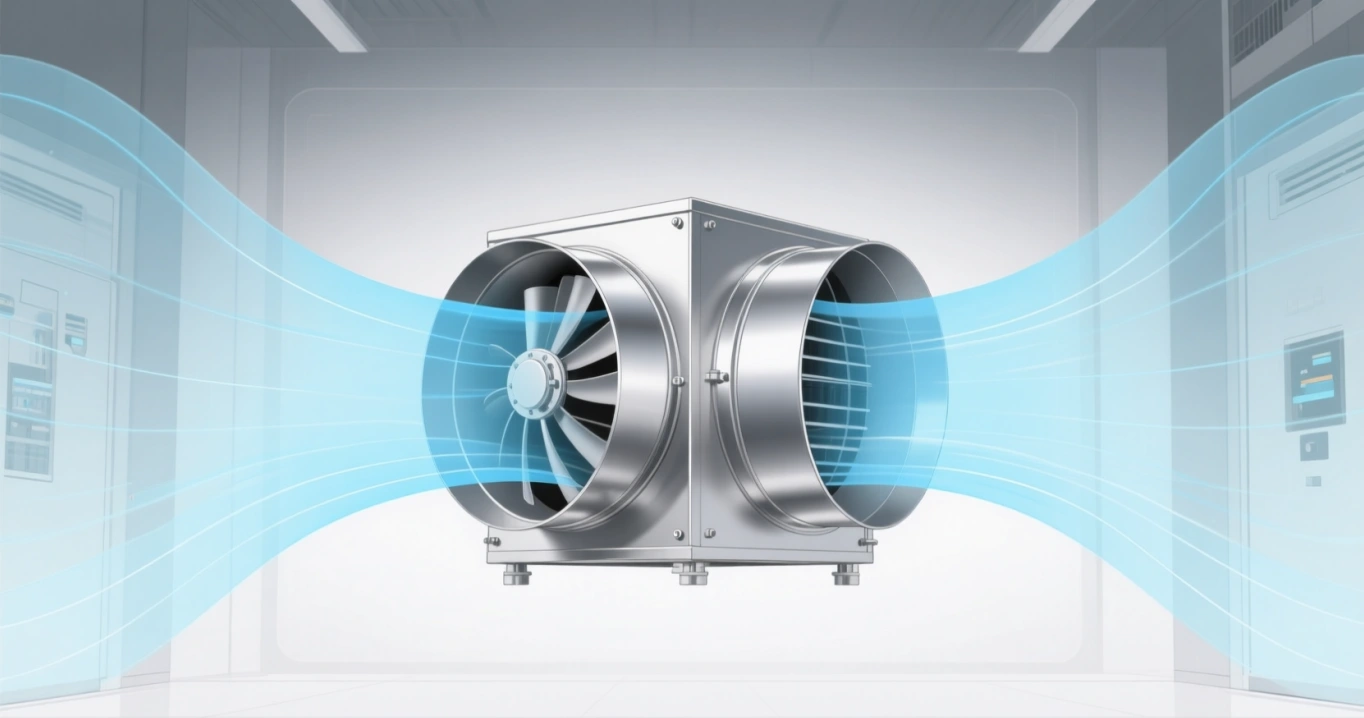

Maintaining a "pressure cascade"—where cleaner rooms have higher pressure than adjacent hallways—is impossible without a high-performance hermetic door. If your sealed door leaks, your HVAC system has to work twice as hard to maintain the environment, leading to massive energy waste and potential regulatory red flags.

Standard industry benchmarks, such as ASTM E283, often require leakage rates to stay below 0.5 cubic feet per minute (CFM). Achieving this requires more than just a heavy slab of material; it requires advanced silicone gasket technology and precision-engineered frames that don't warp over time.

Technical Breakdown: Steel Sealed Doors

When people think of industrial strength, they think of a galvanized steel door or a stainless steel unit. Steel is the "workhorse" of the cleanroom industry for several very good reasons.

1. Unmatched Durability and Longevity

In a high-traffic cleanroom environment, doors are subjected to constant use, impact from carts, and aggressive chemical washes. A stainless steel 304 or 316 sealed door can withstand these stresses for 25 years or more. Unlike lighter materials, steel doesn't crack or degrade when exposed to the harsh VHP (Vaporized Hydrogen Peroxide) sterilization common in pharma.

2. Specialized Shielding and Safety

Steel is naturally versatile. For facilities dealing with sensitive electronics, a steel sealed door can be outfitted for electromagnetic shielding, blocking up to 99% of interference that could ruin a microchip batch. Furthermore, if your facility handles flammable chemicals, a fire-rated door made of steel provides a safety buffer (often up to 90 minutes) that glass simply cannot match without extreme expense.

3. Structural Integrity and Airtight Seals

Because steel is rigid, it holds a manual sliding door or swing door frame perfectly square. This rigidity is what allows for a truly airtight seal. When combined with magnetic strips or heavy-duty gaskets, a steel sealed door creates a vault-like closure that is essential for ISO Class 1-5 facilities.

Limitations of Steel

The most obvious drawback is the "closed-off" feeling. Without a vision panel, a steel door offers zero visibility. While you can add a double-glazed window, the default state is opaque. Additionally, steel is heavy. This requires reinforced hinges and high-quality door closer hardware to ensure the door doesn't become a safety hazard or a burden to operate.

Technical Breakdown: Glass Sealed Doors

The shift toward "Open Concept" cleanrooms has made the glass sealed door a popular choice for R&D labs and hospital isolation wards. It isn't just about looking good; it's about functionality.

1. Enhancing Safety Through Visibility

The primary advantage of a glass entry door is the ability to see what is happening on the other side. Supervisors can monitor processes, and technicians can signal for help without breaking the "seal" of the room. In medical healthcare settings, such as an ICU or a pharmacy compounding room, being able to see a patient or a colleague through a glass door is a safety requirement, not a luxury.

2. Modern Aesthetics and Psychological Well-being

Let's be honest: working in a windowless box is draining. A glass sealed door allows natural light (or at least borrowed light from the corridor) to penetrate the workspace. This improves morale and can even increase productivity in detail-oriented tasks like micro-assembly.

3. Chemical Resistance and Cleanability

High-quality tempered glass is incredibly resistant to most cleaning agents. It won't pit, rust, or discolor. As long as the aluminum profile framing the glass is high-grade, a glass sealed door offers a non-porous surface that is exceptionally easy to keep sterile.

Challenges to Consider

The "weak point" of a glass door is often the frame. If the cleanroom hardware isn't perfectly aligned, the thermal expansion of the glass versus the metal frame can lead to air leaks. Furthermore, while tempered glass is strong, it isn't indestructible. In a heavy industrial area where forklifts or large material skids are moving, a glass exit door might be a liability.

Head-to-Head Comparison: Feature Analysis

To help your procurement team, let's look at how these two stack up across the most important metrics for a sealed door.

| Feature | Steel Sealed Door | Glass Sealed Door |

|---|---|---|

| Primary Material | Stainless Steel (304/316) / Galvanized | Tempered / Laminated Safety Glass |

| Contamination Control | Excellent (Seamless / Flush) | Good (Requires high-quality framing) |

| Air Leakage Rate | Typically < 0.3 CFM | Typically 0.4 - 0.6 CFM |

| Impact Resistance | Very High | Moderate (Shatter-proof) |

| Visibility | Limited (Requires Vision Panel) | Full Transparency |

| Maintenance Needs | Low (Gasket check every 5 years) | Moderate (Frequent cleaning for prints) |

| Ideal ISO Class | ISO 1 - ISO 8 | ISO 6 - ISO 9 |

| Shielding (EMI/RFI) | Available & Effective | Very Limited |

Deep Dive: The Science of the "Seal"

Regardless of whether you choose steel or glass, the "magic" happens at the edges. A sealed door is only as good as its gasket.

Gasket Materials: Silicone vs. EPDM

Most high-end sealed door designs use medical-grade silicone gaskets. Silicone remains flexible across a wide temperature range and doesn't "set" or flatten out as quickly as cheaper rubber. For a pharmaceutical door, this ensures that even after 10,000 openings, the door still hits that airtight benchmark.

Automatic Drop Seals

For a swing door, the gap at the floor is the hardest to seal. Modern sealed door solutions utilize an "automatic drop seal." When the door closes, a mechanical plunger pushes a gasket down to the floor. When it opens, the seal retracts, preventing wear and tear on the gasket and making the door easier to move. This is a critical feature for maintaining particle containment in any controlled environment.

Choosing the Right Door for Your Industry

One size does not fit all. Your specific industry will dictate which sealed door is the "correct" choice.

1. Pharmaceutical and Biotech

In these environments, compliance with GMP compliance and EU Annex 1 is the priority. You need a door that can withstand constant "wash-downs."

- Recommendation: Use a stainless steel 304 sealed door for core production areas and material airlocks. Use a hybrid steel door with a large vision panel for hallways to allow for supervision without entry.

2. Semiconductor and Electronics

Here, the enemy is static and microscopic dust. Electromagnetic shielding and ESD (Electrostatic Discharge) protection are key.

- Recommendation: A powder-coated metal door with ESD-safe finishes is the standard. If you use a sliding door, ensure it is an automatic sliding door to minimize air turbulence caused by human movement.

3. Hospital and Healthcare

In isolation wards or operating theaters, visibility can be a matter of life and death.

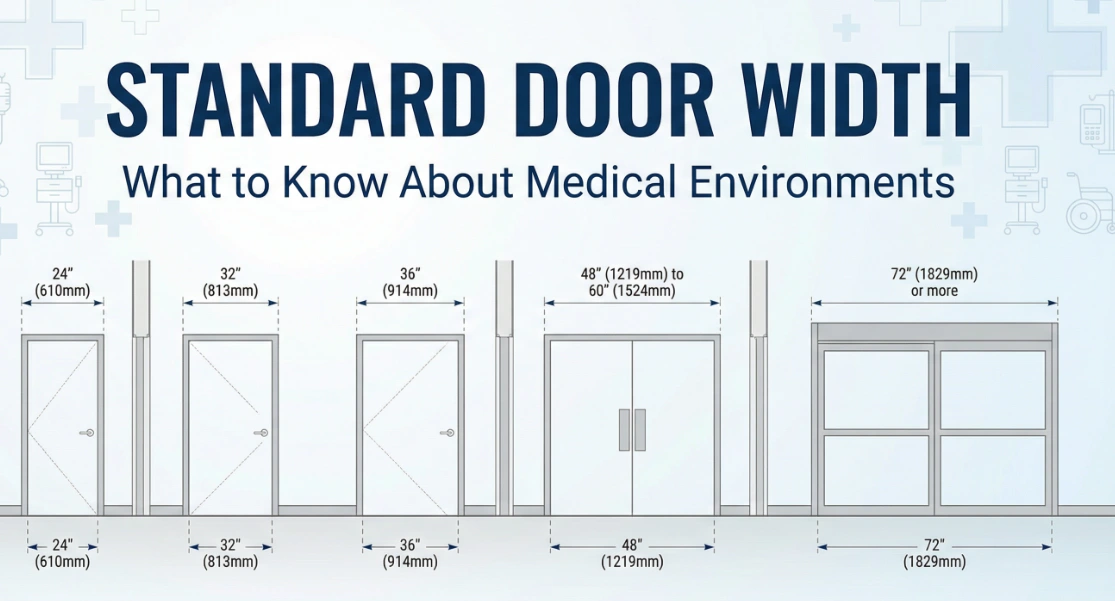

- Recommendation: A glass sealed door with a robust aluminum profile frame. This allows nurses to monitor patients while maintaining a pressurized, sterile environment.

The Financial Reality: Total Cost of Ownership

When a contractor looks at a quote for a sealed door, they often only see the "sticker price." However, the Total Cost of Ownership tells a different story.

- Initial Investment: A glass sealed door is often 15-25% more expensive than a standard steel one due to the cost of specialized tempering and framing.

- Energy Savings: A high-quality sealed door with a low leakage rate can save a facility thousands of dollars in HVAC costs. If your door leaks, your air handling unit (AHU) must run at a higher RPM to maintain pressure. Over 10 years, the "cheaper" door might actually cost you $10,000 more in electricity.

- Maintenance and Downtime: If a door fails and you lose "room integrity," the cost of a production halt in a pharmaceutical plant can exceed $50,000 per hour. Investing in a durable metal door from a trusted brand like E-ZONG is essentially an insurance policy against downtime.

Step-by-Step Selection Guide for Procurement Teams

How do you actually pull the trigger on a purchase? Follow these steps to ensure you don't miss a detail.

Step 1: Audit Your Pressure Requirements

Check your facility's design documents. What is the required pressure differential? If it's high (e.g., >15 Pa), you need a sealed door with a certified leakage report. Don't take the vendor's word for it—ask for the data.

Step 2: Evaluate the Traffic Pattern

Will this door be opened 5 times a day or 500? High-traffic entry door locations should almost always be steel. If visibility is needed, use a double-glazed window insert. For low-traffic observation rooms, glass is a great choice.

Step 3: Consider the Interlock System

In a modern cleanroom construction project, doors are rarely standalone. They are part of an interlock system (or airlock). Ensure your sealed door is compatible with electronic strikes and magnetic locks. A manual sliding door might be cheaper, but an automatic sliding door integrated with the interlock system provides much better contamination control.

Step 4: Verify Material Compatibility

Does your cleaning protocol involve harsh acids or peroxide? Ensure the aluminum profile, steel leaf, and gaskets are rated for those specific chemicals. E-ZONG provides material compatibility charts to help with this validation process.

Why the Right Partner Matters

Selecting a sealed door is a complex engineering task. With 26 years of experience, E-ZONG has seen the evolution of cleanroom standards firsthand. From the early days of basic metal door designs to today's high-precision, CNC-machined hermetic door systems, we provide the expertise needed to navigate ISO and GMP requirements.

Whether you need a custom-sized laboratory door or a fleet of pharmaceutical door units for a new factory, the focus should always be on quality. A door is a 20-year investment. Choosing a partner who understands aluminum profiles, HVAC integration, and the nuances of airtight seal technology ensures that your facility remains compliant and efficient from day one.

Final Thoughts

In the debate of Steel vs. Glass, there is no "loser." Steel provides the muscle and the airtight reliability for core production. Glass provides the visibility and modern feel required for safety and aesthetics. Most modern facilities find that a mix of both—using steel for the heavy lifting and glass for the observation zones—yields the best results.

Ready to secure your facility's integrity?

- Consult with an E-ZONG Cleanroom Expert today for a tailored sealed door assessment. We’ll help you navigate the specs to find the perfect fit for your budget. Contact Us Here

- Download our Technical Checklist: Don’t buy a door until you’ve checked these 15 critical specs.

-

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment -

Top Aluminium Profile Manufacturers in China: Leading the Global Market

Top Aluminium Profile Manufacturers in China: Leading the Global Market -

The Evolution of Air Tight Sliding Doors

The Evolution of Air Tight Sliding Doors -

AHU Aluminium Profile: A Comprehensive Guide

AHU Aluminium Profile: A Comprehensive Guide -

The Importance of Choosing the Right Cleanroom Door in Vietnam

The Importance of Choosing the Right Cleanroom Door in Vietnam -

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety -

.jpg) The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities!

The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities! -

Unlock the Possibilities with AJ Manufacturing Doors

Unlock the Possibilities with AJ Manufacturing Doors -

Make a Statement with Manufactured Home Interior Doors!

Make a Statement with Manufactured Home Interior Doors! -

what is aluminum profile? Aluminum Profiles for Your Home is the best option

what is aluminum profile? Aluminum Profiles for Your Home is the best option

-

Steel vs. Glass Sealed Door for Modern Cleanroom Needs

Steel vs. Glass Sealed Door for Modern Cleanroom Needs -

Double Swing Door vs. Single: Which Fits Your Cleanroom Needs

Double Swing Door vs. Single: Which Fits Your Cleanroom Needs -

Unit Ventilator Explained: Meeting Modern HVAC Needs

Unit Ventilator Explained: Meeting Modern HVAC Needs -

Supply vs. Return HVAC Grilles: Healthcare Selection Guide

Supply vs. Return HVAC Grilles: Healthcare Selection Guide -

Linear Diffuser: The Secret to Modern HVAC Comfort & Design

Linear Diffuser: The Secret to Modern HVAC Comfort & Design -

What to Know About Standard Door Width in Medical Environments

What to Know About Standard Door Width in Medical Environments -

What Is a Return Air Vent and Why Does It Matter in HVAC

What Is a Return Air Vent and Why Does It Matter in HVAC -

Top Materials for Durable Pharma Clean Room Doors

Top Materials for Durable Pharma Clean Room Doors -

Hospital Cleanroom Door Design Requirements

Hospital Cleanroom Door Design Requirements -

Swing Doors vs Standard Doors: Which Is Right for Your Facility

Swing Doors vs Standard Doors: Which Is Right for Your Facility

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.

Speak Your Mind