How Cleanroom Aluminum Profiles Ensure Medical Environment Safety

- By:Lisa

- 2025-08-19

- 29

Cleanrooms are vital for sterile medical settings. Cleanroom aluminum profiles serve as key structural components. They offer lightweight design, corrosion resistance, and flexibility. For example, these profiles are used in operating rooms, ICUs, and cleanroom doors. This article explores how cleanroom aluminum profiles ensure safety. Specifically, they leverage superior materials, precision manufacturing, and strict quality standards.

1. Key Advantages of Cleanroom Aluminum Profiles

Cleanroom aluminum profiles excel due to unique properties. They are ideal for medical cleanroom construction. Here are their core advantages:

- Lightweight and Strong

Cleanroom aluminum profiles have a density of 2.7 g/cm³. This is much lower than steel’s 7.8 g/cm³. Yet, they maintain tensile strength ≥200 MPa. As a result, they ensure robust frameworks for cleanroom doors. For instance, they suit operating rooms and ICUs. Their lightweight nature simplifies installation. - Corrosion Resistance

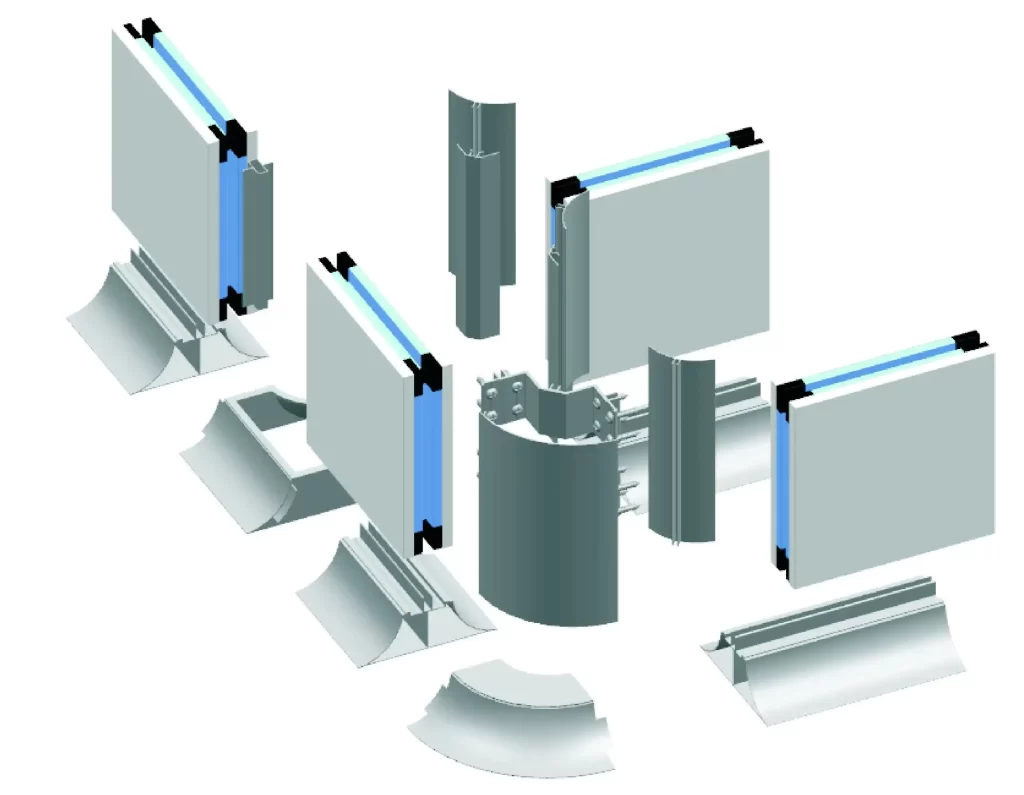

Medical facilities face high humidity and disinfectants like sodium hypochlorite. The aluminum oxide layer (Al₂O₃) on cleanroom aluminum profiles resists corrosion. Consequently, it withstands harsh cleaning agents. This extends cleanroom door lifespan and reduces contamination risks. - Modular Design

Precision extrusion allows customized shapes with ±0.1 mm tolerances. Thus, cleanroom aluminum profiles support modular design. This enables rapid assembly. Moreover, it simplifies cleanroom construction and modifications. For example, it reduces dust pollution, meeting cleanroom standards. - Antibacterial Properties

Anodizing or antibacterial coatings (e.g., nano-silver) create smooth surfaces. These meet ISO 14644 standards (ISO 5: ≤3,520 particles/m³ at 0.5 μm). Therefore, they inhibit bacterial growth. This is critical for ICUs and cleanroom doors, reducing infection risks.

2. Applications in Medical Settings

Cleanroom aluminum profiles are essential in medical cleanrooms. They ensure sterile environments. Their key applications include:

- Wall and Partition Systems

Operating rooms and ICUs require strict cleanroom standards. Cleanroom aluminum profiles provide smooth surfaces and precise joints (±0.1 mm tolerance). Thus, they block dust and microbes. They meet ISO 14644 requirements. Additionally, their modular design minimizes construction contamination. - Ceiling and Floor Supports

Cleanroom ceilings house HEPA/ULPA filters. Floors support heavy equipment. Cleanroom aluminum profiles offer strength and lightweight properties. For example, they resist frequent disinfection. Their modular design also simplifies maintenance. - Equipment and Piping Frameworks

Cleanroom aluminum profiles support CT scanners and ventilators. Their versatility allows custom designs. Furthermore, their modular design eases equipment upgrades. This reduces contamination risks, ensuring hospital environment safety. - Cleanroom Doors and Sealing Systems

Cleanroom aluminum profiles form cleanroom door frameworks. Anodizing and antibacterial coatings ensure easy cleaning. Paired with silicone seals, they maintain positive pressure (10-20 Pa). As a result, they ensure airtightness. This complies with ISO 9001 and GMP standards.

3. Mechanisms for Ensuring Safety

Cleanroom aluminum profiles provide multiple safety mechanisms. These protect medical environments effectively.

- Air Contamination Control

Smooth surfaces of cleanroom aluminum profiles reduce particle adhesion. Consequently, they meet ISO 14644 standards. For example, they ensure air contamination control in operating rooms and cleanroom doors. - Antibacterial Protection

Antibacterial coatings suppress pathogens like Staphylococcus aureus. Thus, they reduce infection risks in ICUs. Moreover, they ease cleaning efforts for cleanroom doors. - Airtight Integrity

Precision manufacturing (±0.1 mm tolerance) ensures tight joints. This maintains positive pressure in cleanrooms. Therefore, it blocks external contaminants effectively. - Easy Cleaning and Low Maintenance

Cleanroom aluminum profiles resist corrosion from disinfectants like 75% ethanol. Their modular design simplifies maintenance. As a result, they reduce costs and contamination risks. This aligns with ISO 9001 principles.

4. Technical Standards and Compliance

Cleanroom aluminum profiles meet strict standards. These ensure reliability in medical settings.

- Material Performance

- Cleanliness: Smooth surfaces meet ISO 14644 (ISO 5).

- Antibacterial Properties: Comply with GMP standards.

- Strength: Tensile strength ≥200 MPa, density 2.7 g/cm³.

- Manufacturing Precision

Extrusion tolerances of ±0.1 mm ensure airtightness. They also support modular design stability. - Quality Certifications

Third-party certifications (e.g., SGS, TÜV) validate corrosion resistance. They also confirm antibacterial properties and airtightness. These meet ISO 9001 and GMP standards.

5. Real-World Case Studies

- Tertiary Hospital Operating Room Upgrade

A hospital used cleanroom aluminum profiles for walls and cleanroom doors. The modular design cut construction time by 30%. It also reduced dust pollution. Antibacterial coatings met ISO 14644 standards. As a result, surgical infection rates dropped by 20%. - Pharmaceutical Cleanroom Facility

A pharmaceutical plant used cleanroom aluminum profiles for partitions. Their corrosion-resistant properties withstood intense disinfection. The modular design reduced retrofitting time by 50%. Consequently, microbial contamination fell by 40%. This met GMP standards.

6. Conclusion

Cleanroom aluminum profiles are vital for medical cleanrooms. Their lightweight (2.7 g/cm³) and corrosion-resistant properties excel. Precision manufacturing (±0.1 mm) ensures airtightness. Additionally, antibacterial coatings maintain sterile environments. These meet ISO 14644, GMP, and ISO 9001 standards. By enabling fast construction and low maintenance, cleanroom aluminum profiles enhance hospital environment safety. Thus, they protect patients and healthcare staff effectively.

-

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment -

Top Aluminium Profile Manufacturers in China: Leading the Global Market

Top Aluminium Profile Manufacturers in China: Leading the Global Market -

The Evolution of Air Tight Sliding Doors

The Evolution of Air Tight Sliding Doors -

AHU Aluminium Profile: A Comprehensive Guide

AHU Aluminium Profile: A Comprehensive Guide -

The Importance of Choosing the Right Cleanroom Door in Vietnam

The Importance of Choosing the Right Cleanroom Door in Vietnam -

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety -

.jpg) The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities!

The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities! -

Unlock the Possibilities with AJ Manufacturing Doors

Unlock the Possibilities with AJ Manufacturing Doors -

Make a Statement with Manufactured Home Interior Doors!

Make a Statement with Manufactured Home Interior Doors! -

what is aluminum profile? Aluminum Profiles for Your Home is the best option

what is aluminum profile? Aluminum Profiles for Your Home is the best option

-

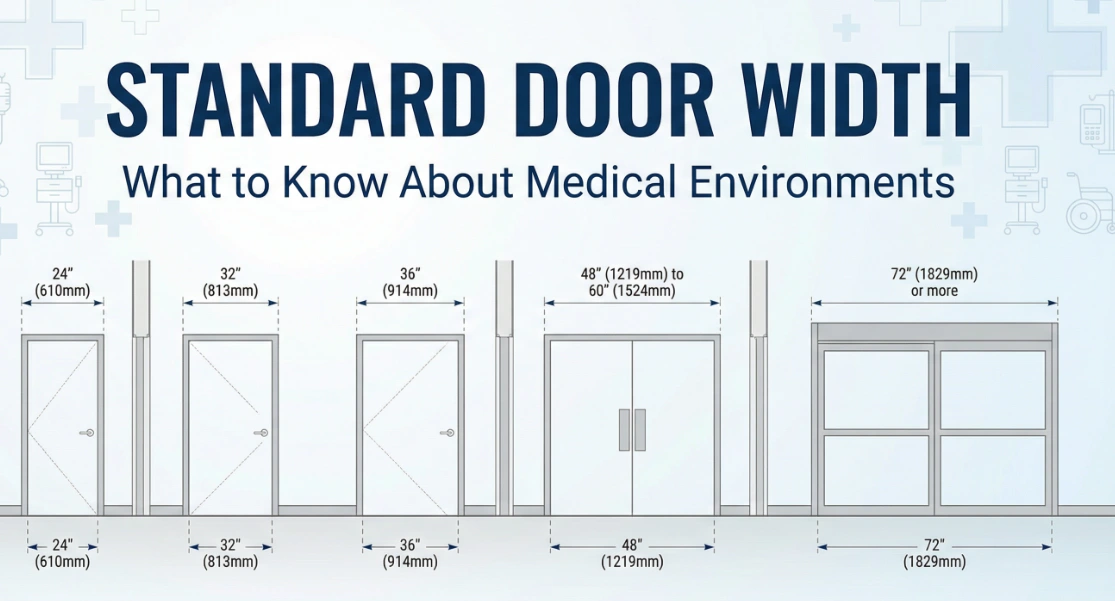

What to Know About Standard Door Width in Medical Environments

What to Know About Standard Door Width in Medical Environments -

What Is a Return Air Vent and Why Does It Matter in HVAC

What Is a Return Air Vent and Why Does It Matter in HVAC -

Top Materials for Durable Pharma Clean Room Doors

Top Materials for Durable Pharma Clean Room Doors -

Hospital Cleanroom Door Design Requirements

Hospital Cleanroom Door Design Requirements -

Swing Doors vs Standard Doors: Which Is Right for Your Facility

Swing Doors vs Standard Doors: Which Is Right for Your Facility -

Cleanroom Door Materials Explained: Key Types and Applications

Cleanroom Door Materials Explained: Key Types and Applications -

How Do Different Vent Grills Impact Medical Cleanrooms

How Do Different Vent Grills Impact Medical Cleanrooms -

Controlled Environment vs Air Clean Room Differences Explained

Controlled Environment vs Air Clean Room Differences Explained -

How to Extend the Life of Your Exterior Steel Door

How to Extend the Life of Your Exterior Steel Door -

What Are the Best Materials for AC Vent Covers

What Are the Best Materials for AC Vent Covers

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.

Speak Your Mind