Hospital airtight automatic door: the first choice for sterile environment

- By:Lisa

- 2025-08-07

- 29

1. Introduction to Hermetic Automatic Doors

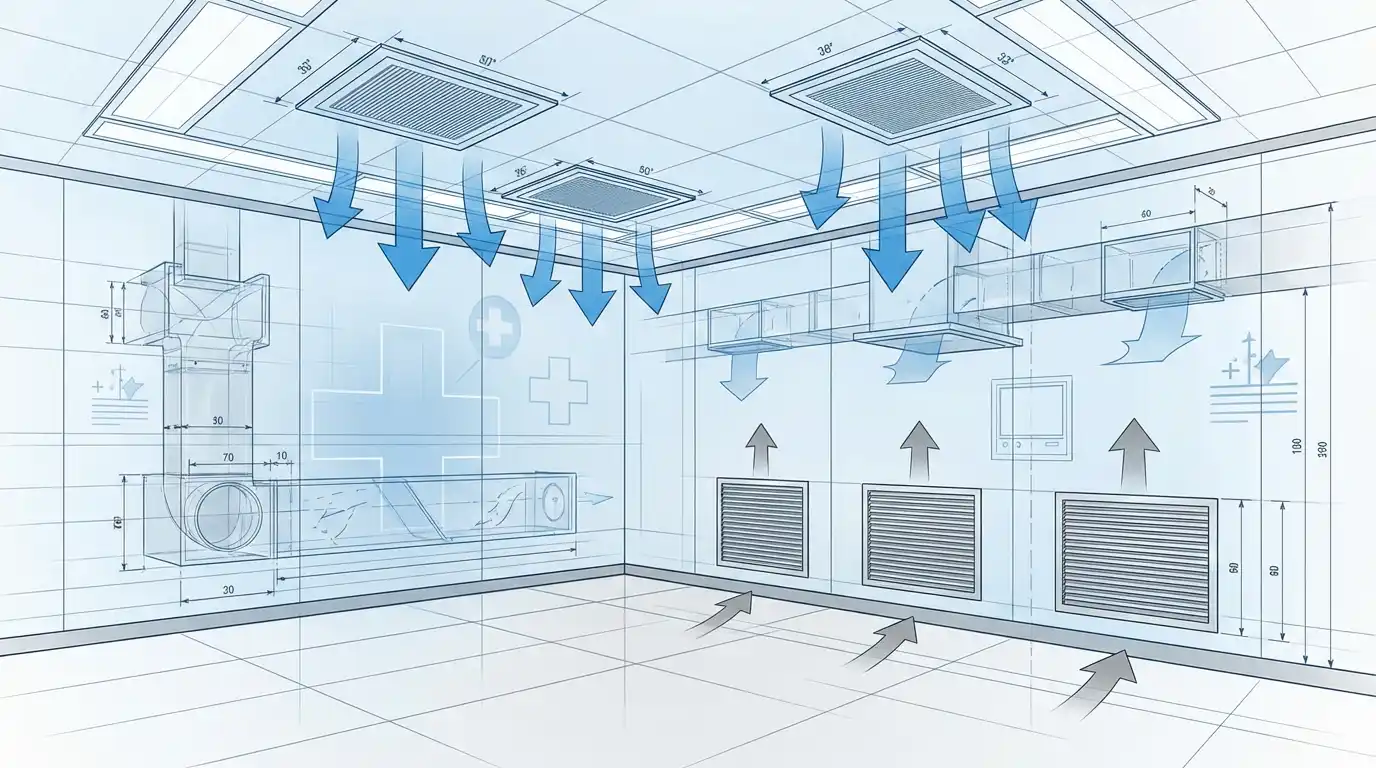

In hospitals, maintaining a sterile environment is critical to patient safety, and hermetic automatic doors (airtight operating room doors) play a pivotal role with their cleanroom door design. These doors are engineered to create a tight seal, blocking airborne contaminants and ensuring cleanliness in areas like operating rooms and isolation wards. Their core features—automatic operation and hermetic sealing (a precision structure that prevents air leakage)—minimize human contact, reducing the risk of cross-contamination.

Picture this: in a bustling operating room, staff move in and out frequently. A poorly sealed door could let bacteria slip through, endangering patients. Hermetic automatic doors act as an invisible barrier, safeguarding against such risks while upholding medical standards through the durability of hospital steel doors. Paired with HVAC diffusers (available for purchase), these doors work seamlessly with hospital air management systems to maintain positive or negative pressure, ensuring controlled airflow and keeping contaminants out of cleanroom steel doors.

Key Benefits

- Maintaining Sterility: Their cleanroom swing door design, combined with round ceiling air diffusers, ensures operating rooms remain pristine.

- Noise Reduction: The sealing of hospital steel doors blocks external noise, creating a quiet environment for surgical focus.

- Energy Efficiency: Using purification aluminum profiles, these doors minimize air leakage, reducing energy costs.

- Antibacterial and Durable: Made with powder-coated aluminum profiles or stainless steel, they’re easy to clean and built for high-traffic hospital settings.

Hermetic automatic doors are now a standard for GMP-compliant cleanroom doors, widely used in new hospitals and retrofitting projects.

2. Core Features of Hermetic Automatic Doors

Hermetic automatic doors excel in cleanroom door design, making them guardians of sterile zones. Here are their standout features:

- Hermetic Sealing Technology

With a precision-engineered airtight operating room door structure, these doors seal tightly when closed, preventing air movement and blocking contaminants from entering hospital double door areas. Paired with linear bar diffusers, they ensure airflow follows designated paths, minimizing bacterial intrusion. - Touchless Operation

Staff can enter with a simple approach, triggering automatic opening without physical contact. This reduces contamination risks and boosts efficiency, especially during emergencies when cleanroom swing doors enable swift access. - Antibacterial, Durable Materials

Built with hospital steel doors or aluminum cleanroom doors, they feature antimicrobial coatings, resisting corrosion and simplifying cleaning while withstanding frequent use. - Smooth, Seamless Design

Cleanroom steel doors have a sleek, non-porous surface, eliminating bacterial breeding grounds. Regular disinfection further reduces infection risks.

3. Advantages for Sterile Environments

Hermetic automatic doors are a cornerstone of contamination control, leveraging precise pressure regulation alongside tools like jet nozzle diffusers to maintain positive or negative pressure in operating rooms or isolation wards. Their key advantages include:

- Precise Airflow Control

Working with HVAC diffusers, they ensure controlled airflow, protecting areas like laboratory doors from external contaminants. - Reduced Pathogens and Particles

Standard doors can increase airborne particle levels by 15%-25% when opened, but airtight operating room doors keep this to a minimum, safeguarding vulnerable patients. - Enhanced Infection Control

In hospital double door settings like operating rooms or ICUs, these doors minimize air turbulence, maintaining sterility and reducing hospital-acquired infections. - Compliance with Standards

They meet GMP-compliant cleanroom door standards, ensuring regulatory compliance.

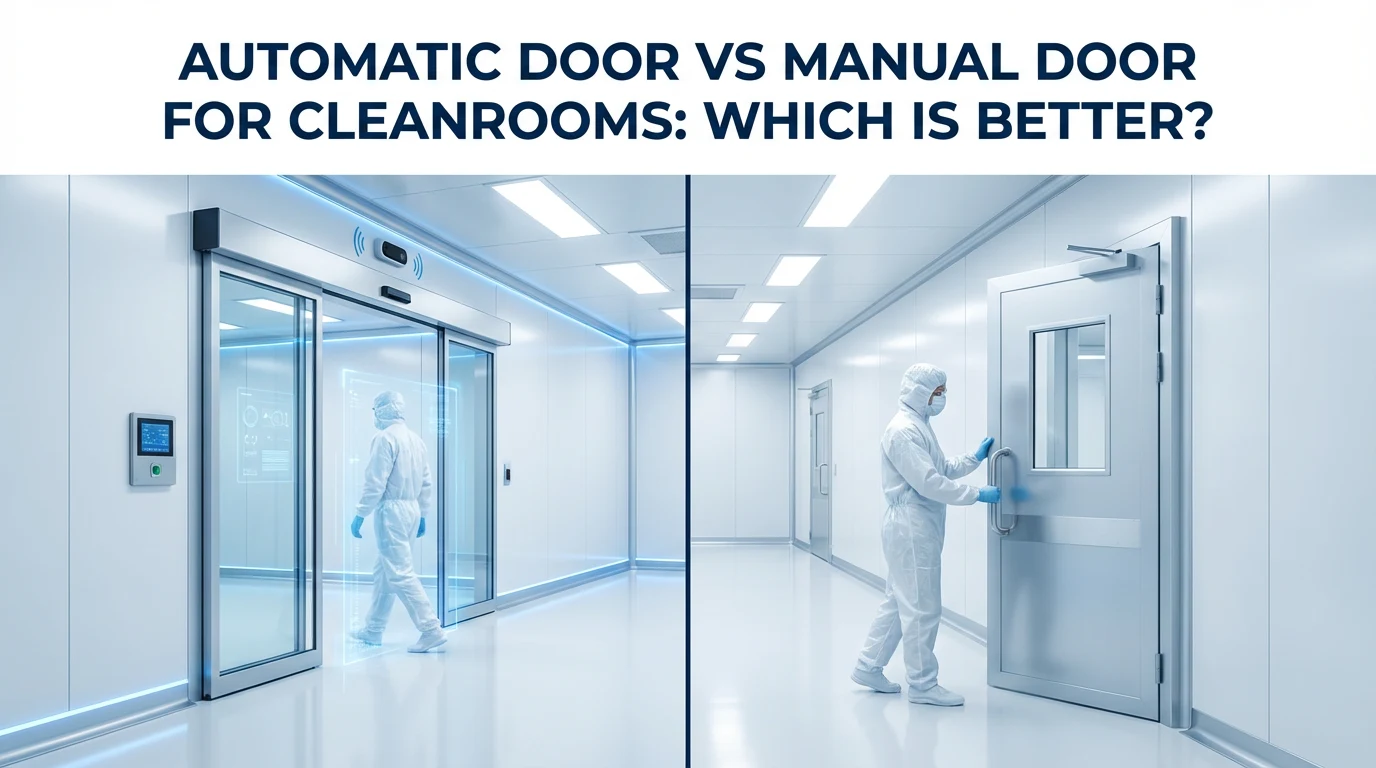

4. Comparison with Traditional Doors

Traditional manual or non-hermetic doors fall short in hospital settings:

- Cross-Contamination Risk: Manual standard doors accumulate bacteria on handles.

- Poor Sealing: Contaminants seep through gaps, compromising cleanroom swing door environments.

- Air Turbulence: Opening them spikes particle levels, endangering patients.

Hermetic automatic doors address these issues:

- Touchless Sensors: Eliminate contamination risks.

- Hermetic Sealing: Paired with round ceiling air diffusers, they maintain stable sterile conditions.

- Antibacterial Materials: Hospital steel doors or powder-coated aluminum profiles are smooth and easy to sanitize.

Data Comparison:

- Standard doors: Particle levels rise 20%-30% during opening.

- Airtight operating room doors: Limit increases to under 5%, reducing infection rates by ~15%.

- Compliant with GMP-compliant cleanroom door standards.

5. Applications in Hospital Settings

Hermetic automatic doors shine in critical hospital environments:

- Operating Rooms

Airtight operating room doors work with positive pressure systems to block bacteria and particles, maintaining a sterile field. Touchless operation reduces contamination risks. - Intensive Care Units (ICUs)

Cleanroom steel doors use pressure control and antibacterial surfaces to protect immunocompromised patients. - Isolation Wards

Paired with negative pressure systems, they prevent pathogen spread, ensuring safety for staff and patients. - Cleanrooms and Laboratories

Laboratory doors and aluminum cleanroom doors maintain contamination-free environments for drug development or testing, meeting GMP-compliant cleanroom door standards.

6. Technical Advantages in Hospital Operations

Hermetic automatic doors deliver significant operational benefits:

- Seamless Air System Integration

They sync with aluminum profiles for air treatment units and HVAC diffusers, boosting cleanliness and system efficiency. - Noise Reduction

Cleanroom swing doors keep noise below 30 decibels, compared to 50 for standard doors, enhancing comfort. - Energy Efficiency

Purification aluminum profiles cut air leakage, saving 10%-15% on energy costs. - Customizability

Options like medical lead doors cater to imaging suites or AHU aluminum profile frames for specialized needs.

7. Maintenance and Durability

Hermetic automatic doors are low-maintenance and built to last:

- Easy to Clean

Hospital steel doors or powder-coated aluminum profiles have smooth surfaces, easily sanitized with standard disinfectants. - High Durability

Designed for thousands of daily cycles, they boast a failure rate below 1% and a lifespan exceeding 10 years. - Simple Maintenance Routine

- Inspect gaskets for airtightness.

- Clean and lubricate tracks.

- Test sensor sensitivity.

- Calibrate sealing performance with systems like linear bar diffusers.

Annual or biannual maintenance keeps costs low and ensures sterile environment stability.

8. Implementation Considerations

Factors for Choosing Hermetic Automatic Doors

- Airtightness: Leakage rate below 0.1 m³/(h·m²).

- Materials: Cleanroom steel doors or aluminum cleanroom doors, durable and easy to clean.

- Ease of Use: Sensor-based operation reduces infection risks.

- Durability: Handles tens of thousands of cycles.

- Customization: Supports medical lead doors or custom aluminum frames for AHU.

Installation and Compatibility

- Precise Measurements: Ensure hospital double doors fit seamlessly with walls.

- Power Planning: Require 220V with backup power.

- Fire Safety Compliance: Allow manual mode in emergencies.

- Minimized Disruption: Install during off-hours to avoid impacting hospital operations.

Cost-Benefit Analysis

| Feature | Standard Doors | Airtight Operating Room Doors |

|---|---|---|

| Airtightness | 0.5 m³/(h·m²) | 0.1 m³/(h·m²) |

| Material Lifespan | 5-8 years | 10-15 years |

| Maintenance Frequency | Every 6 months | Every 12 months |

| Energy Use | Higher | Lower (10%-15% savings) |

| Initial Cost | Lower | Higher |

Hermetic automatic doors recoup costs in 5-7 years through reduced maintenance, energy savings, and lower infection rates, boosting hospital reputation.

-

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment

-

Top Aluminium Profile Manufacturers in China: Leading the Global Market

-

The Evolution of Air Tight Sliding Doors

-

AHU Aluminium Profile: A Comprehensive Guide

-

The Importance of Choosing the Right Cleanroom Door in Vietnam

-

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety

-

The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities!

-

Unlock the Possibilities with AJ Manufacturing Doors

-

Make a Statement with Manufactured Home Interior Doors!

-

what is aluminum profile? Aluminum Profiles for Your Home is the best option

-

Automatic Door vs Manual Door for Cleanrooms: Which Is Better

-

Steel vs. Glass Sealed Door for Modern Cleanroom Needs

-

Double Swing Door vs. Single: Which Fits Your Cleanroom Needs

-

Unit Ventilator Explained: Meeting Modern HVAC Needs

-

Supply vs. Return HVAC Grilles: Healthcare Selection Guide

-

Linear Diffuser: The Secret to Modern HVAC Comfort & Design

-

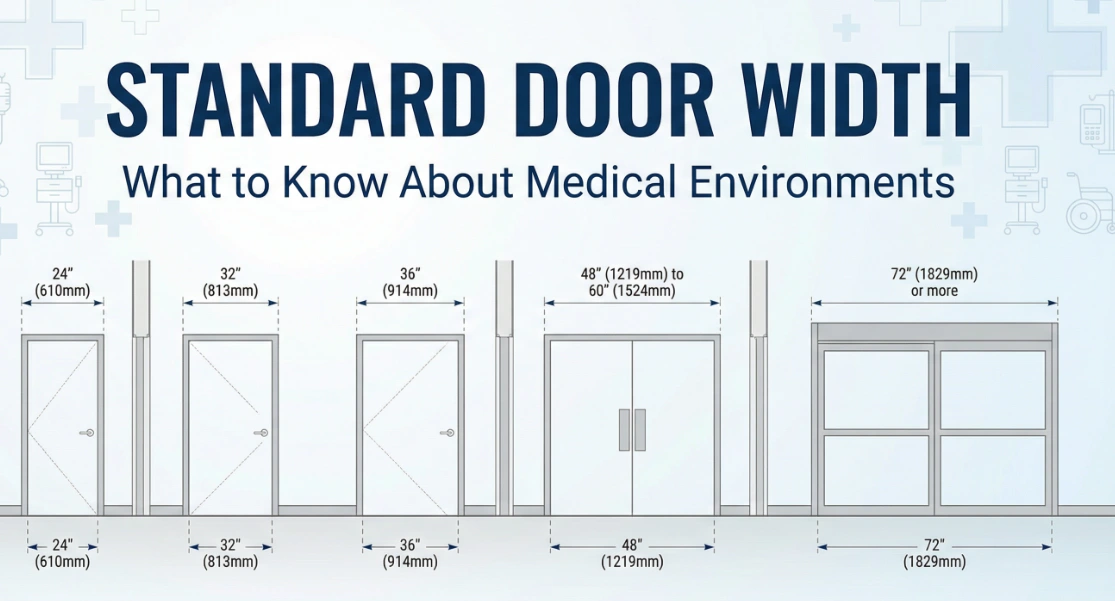

What to Know About Standard Door Width in Medical Environments

-

What Is a Return Air Vent and Why Does It Matter in HVAC

-

Top Materials for Durable Pharma Clean Room Doors

-

Hospital Cleanroom Door Design Requirements

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.

.jpg)

Speak Your Mind