Great Performance Clean Room Door Overview

- By:hqt

- 2022-05-24

- 29

Due to strict regulations, most pharmaceutical and life science products must be manufactured under clean room conditions. A high performance clean room door is the first step to ensuring a safe and clean environment, and choosing the right door for this highly specialized environment is essential. To support regulatory compliance and product quality, these high-performance doors ensure your cleanroom achieves the highest levels of purity and quality.

Common use cases for cleanroom doors:

- Medical institutions

- Pharmaceutical company

- Food storage

Benefits of High Performance Cleanroom Doors

✓ Appropriate Humidity Levels: Fluctuating humidity levels can make employees uncomfortable in cleanrooms, which can lead to costly errors or production delays. High humidity levels can also cause many problems in cleanrooms, such as:

- Bacterial growth

- Degradation or damage to the product

- corrosion

- Static electricity (which can interfere with the movement of particles in the clean room)

High-performance doors can help you easily maintain cleanroom humidity levels specified by standard cleanroom guidelines.

✓ Temperature Control: When cleaning technicians shiver or sweat, the environment can become contaminated and affect production standards as they release more particles into the air. Even small fluctuations in cleanroom temperature can cause problems for people and products. To ensure employee comfort and maintain product integrity, high-performance clean room door system helps regulate the temperature in the cleanroom, which must be maintained at 69.8°F (21°C).

✓ High Quality Gaskets: To keep contaminants out, look for high performance doors that include full size gaskets. Good sealing properties maintain cleanliness levels and ensure high quality production.

✓ Fast opening and closing speed: To minimize air intrusion and entry of contaminants, cleanroom doors should be high-speed doors that open and close as quickly as possible.

✓ Differential pressure control: To prevent cross-contamination between environments and prevent contaminants from entering production areas from adjacent areas, high-performance doors will help maintain proper pressurization in cleanrooms.

✓ Cleanability: To allow thorough rinsing to virtually eliminate potential sites of bacterial manifestation, high performance doors are engineered in a variety of materials for easy cleaning.

✓ Hands-free activation option: Automatic activation devices for clean roll-up doors provide a hands-free method of opening and closing cleanroom doors for a variety of environments such as wave opening sensors and motion / presence detectors.

-

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment

-

Top Aluminium Profile Manufacturers in China: Leading the Global Market

-

The Evolution of Air Tight Sliding Doors

-

AHU Aluminium Profile: A Comprehensive Guide

-

The Importance of Choosing the Right Cleanroom Door in Vietnam

-

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety

-

The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities!

-

Unlock the Possibilities with AJ Manufacturing Doors

-

Make a Statement with Manufactured Home Interior Doors!

-

what is aluminum profile? Aluminum Profiles for Your Home is the best option

-

High Speed Clean Room Doors Cut Contamination Risk

-

Dustproof Cleanroom Door Innovation for Sterile Spaces

-

How Cleanroom Half Glass Swing Door Enhances Sterile Access

-

Why Custom Cleanroom Aluminum Profile Matters Today

-

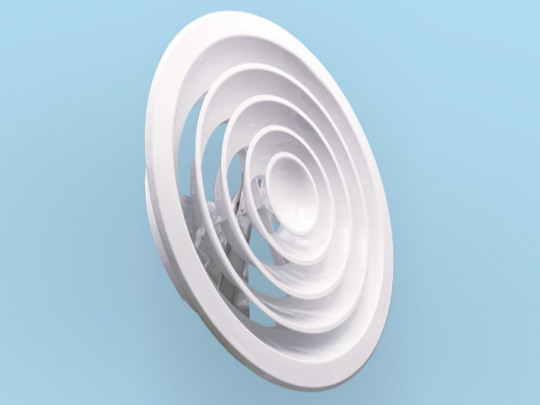

Smart Ceiling Air Diffuser: Dampers Add Full Control

-

E-ZONG: Trusted Air Tight Sliding Cleanroom Door Manufacturer

-

Top Benefits of Clean Room Roll Up Door Systems

-

Cleanroom Glass Door Innovations You Should Know

-

Improve Airflow With the Right Air Diffuser Vent

-

Why Every Laboratory Needs a Sealed Cleanroom Door

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.

.jpg)

Speak Your Mind