GMP Pharmaceutical and Laboratory Doors and Windows

- By:ren

- 2022-12-05

- 29

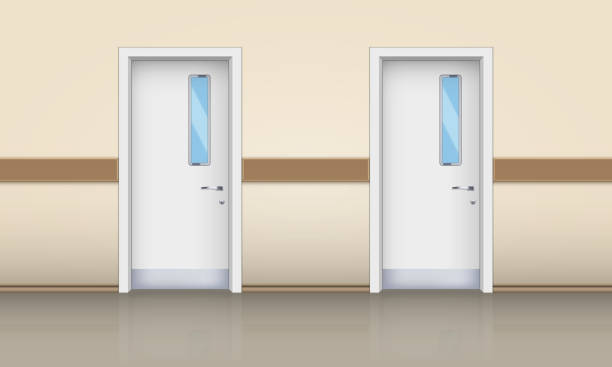

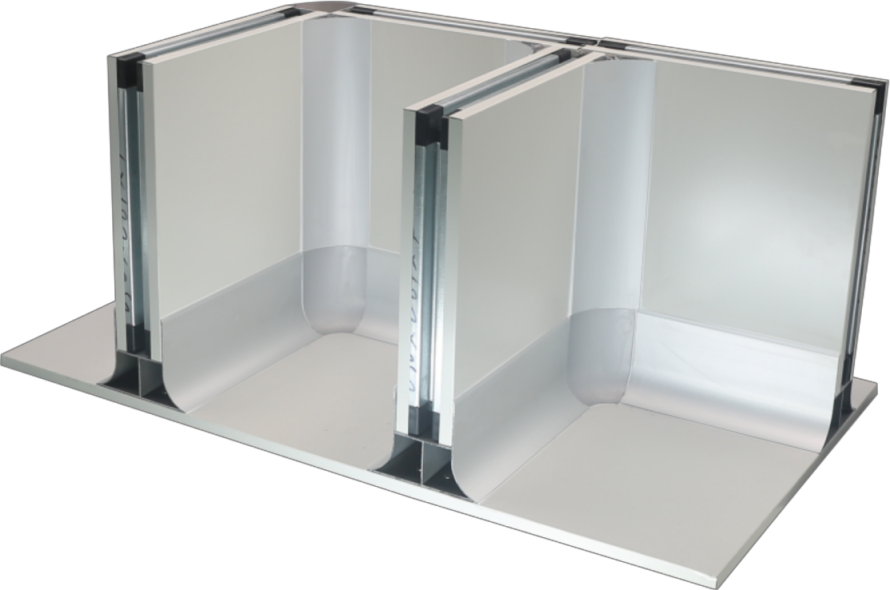

GMP Pharmaceutical and Laboratory Doors and Windows are essential components of any production environment. They provide a secure and sterile environment while allowing personnel access to the production areas. By ensuring the highest standards of safety and quality, these doors and windows are designed with the latest technologies to meet the most exacting standards. From walk-in refrigeration units to laboratory containment areas, GMP Pharmaceutical and Laboratory Doors and Windows provide a reliable and secure product for any facility. With a wide range of sizes and materials, these doors and windows can be customized to meet the individual needs of any facility. With the added protection of corrosion-resistant finishes and the ability to withstand extreme temperatures, these doors and windows offer a long-lasting, low-maintenance solution that ensures personnel safety and product quality. With their superior craftsmanship, GMP Pharmaceutical and Laboratory Doors and Windows provide the perfect solution for any facility.

Benefits of using GMP Pharmaceutical and Laboratory Doors and Windows

Manufacturers will often optimize their production processes to get as much out of the equipment as possible, which automatically leads to a higher risk of contamination and product damage. GMP Pharmaceutical and Laboratory Doors and Windows can help mitigate the risk of contamination and product damage by effectively controlling flow and pressure. Laboratory and pharmaceutical environments are usually very clean, which is great for minimizing the risk of biological contamination. However, it also means that they are extremely sensitive to pressure and flow. If there is any variation in pressure or flow, it can have disastrous effects on the cleanliness of the environment. GMP Pharmaceutical and Laboratory Doors and Windows are engineered to manage flow and pressure for these sensitive environments. GMP Pharmaceutical and Laboratory Doors and Windows are built to last. They are designed to withstand extreme temperatures so they can be used in cool rooms, freezers, and other production areas that require temperature control. They are also built to withstand repeated pressure, making them suitable for environments where there is a lot of foot traffic or other high-pressure areas. This makes GMP Pharmaceutical and Laboratory Doors and Windows suitable for a variety of industrial and laboratory settings.

The importance of high-quality materials

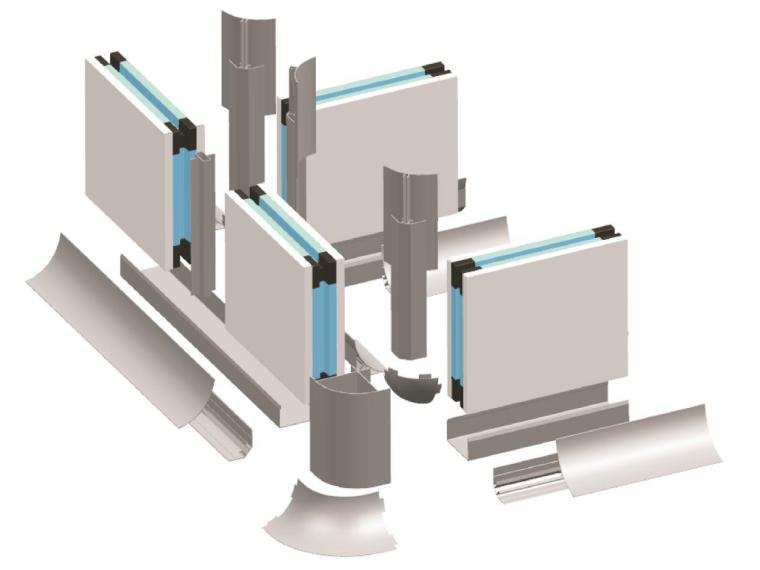

There are a wide range of materials that can be used to manufacture the doors of a pharmaceutical or laboratory door, each with their own set of ups and downs. The best material for a door in your production environment depends on the specifics of that environment. For example, if you are in a humid environment, a material like stainless steel can corrode. If you are in an area with a lot of moisture, you may not want to use wood as a door material because wood can swell in high-humidity environments. If you are in an area with extreme temperatures, you may not want to use a material like wood, which can warp in extreme temperatures. As you can see, the material selection for your door is critical to its successful operation.

Corrosion-resistant finishes and extreme temperatures

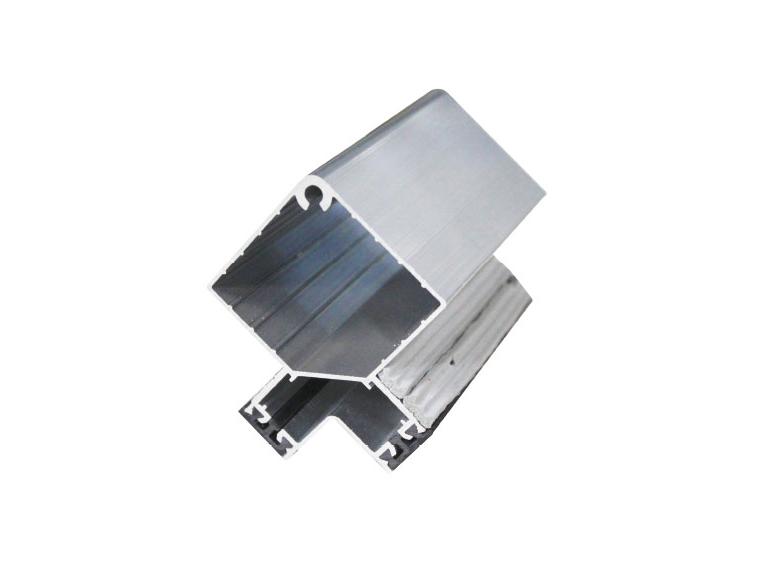

GMP Pharmaceutical and Laboratory Doors and Windows are built with a wide range of corrosion-resistant finishes to withstand extreme temperatures. When selecting a door or window, it is important to take into account the conditions in the environment where it will be used. In a pharmaceutical or laboratory environment, it is important to select materials that can withstand a wide range of temperatures. For example, if the product is going to be used in a walk-in refrigerator, the door will be exposed to temperatures ranging from -40°C to +18°C. When selecting a door or window, it is important to take into account the conditions in the environment where it will be used. In a pharmaceutical or laboratory environment, it is important to select materials that can withstand a wide range of temperatures. Some materials, like wood, do not perform well under extreme temperatures. Wood swells when it comes in contact with water, so it may not make a suitable material for a pharmaceutical or laboratory door that is regularly used with water.

Customizing GMP Pharmaceutical and Laboratory Doors and Windows

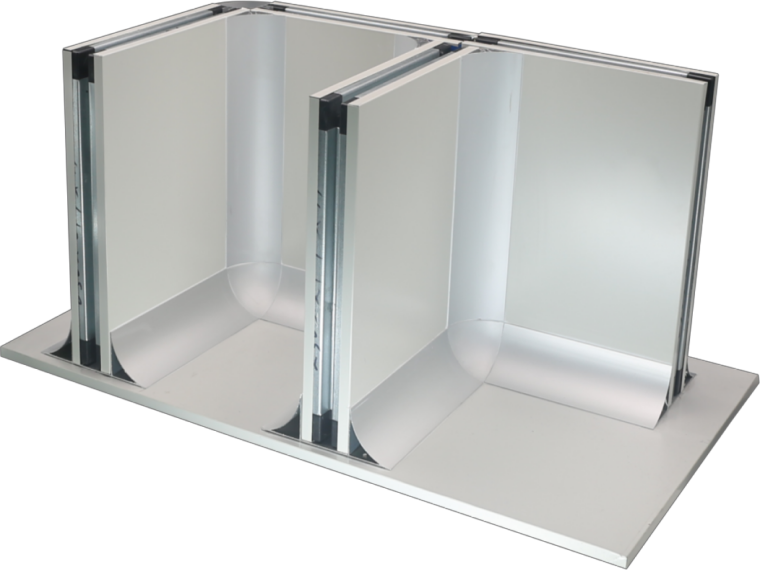

Customization can be important to make sure the right door or window is used for a specific application. When selecting a door or window, make sure it meets the necessary specifications, including the dimensions and the pressure and flow requirements. If you need a custom door or window, make sure the manufacturer has the ability to produce the door or window in the desired size. It is important to know the intended application for the door or window. For example, a walk-in door used in a laboratory setting will be different than a walk-in door used in a refrigerated environment. Once you know what you need, make sure the manufacturer can meet your specific needs.

Long-term performance and low-maintenance

The materials used in making a door or window play a key role in the long-term performance of the door. For example, stainless steel is a popular choice for a door or window because it is strong and durable, as well as corrosion-resistant, making it a great long-term option. Wood, on the other hand, is a more fragile material that requires regular maintenance to keep it in good condition. It is important to consider the long-term performance of the door or window once it is installed. If you are installing a door or window made of a fragile material, you may have to replace it more often than a door or window made of a more durable material.

Superior craftsmanship

The materials used in making a door or window are important, but so is the craftsmanship used to make them. Poor craftsmanship can lead to issues with the door or window being improperly installed or a door or window that does not fit correctly. When selecting a manufacturer, it is important to make sure they have a good reputation and provide high-quality products. It is also important to inspect the manufacturer’s facilities and make sure they meet your standards for quality and safety.

Conclusion

GMP Pharmaceutical and Laboratory Doors and Windows are essential components of any production environment. They provide a secure and sterile environment while allowing personnel access to the production areas. By ensuring the highest standards of safety and quality, these doors and windows are designed with the latest technologies to meet the most exacting standards. From walk-in refrigeration units to laboratory containment areas, GMP Pharmaceutical and Laboratory Doors and Windows provide a reliable and secure product for any facility. With a wide range of sizes and materials, these doors and windows can be customized to meet the individual needs of any facility. With the added protection of corrosion-resistant finishes and the ability to withstand extreme temperatures, these doors and windows offer a long-lasting, low-maintenance solution that ensures personnel safety and product quality. With their superior craftsmanship, GMP Pharmaceutical and Laboratory Doors and Windows provide the perfect solution for any facility.

-

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment -

Top Aluminium Profile Manufacturers in China: Leading the Global Market

Top Aluminium Profile Manufacturers in China: Leading the Global Market -

The Evolution of Air Tight Sliding Doors

The Evolution of Air Tight Sliding Doors -

AHU Aluminium Profile: A Comprehensive Guide

AHU Aluminium Profile: A Comprehensive Guide -

The Importance of Choosing the Right Cleanroom Door in Vietnam

The Importance of Choosing the Right Cleanroom Door in Vietnam -

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety -

.jpg) The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities!

The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities! -

Unlock the Possibilities with AJ Manufacturing Doors

Unlock the Possibilities with AJ Manufacturing Doors -

Make a Statement with Manufactured Home Interior Doors!

Make a Statement with Manufactured Home Interior Doors! -

what is aluminum profile? Aluminum Profiles for Your Home is the best option

what is aluminum profile? Aluminum Profiles for Your Home is the best option

-

Designing a Flexible Clean Room Aluminum Profile System

Designing a Flexible Clean Room Aluminum Profile System -

Look for in Cleanroom Aluminum Profile Wholesaler. Here to Know

Look for in Cleanroom Aluminum Profile Wholesaler. Here to Know -

HVAC Air Diffusion Products Myths Debunked: What You Really Need to Know

HVAC Air Diffusion Products Myths Debunked: What You Really Need to Know -

Why Opt Aluminum Profiles For Air Handling Units: Custom Service

Why Opt Aluminum Profiles For Air Handling Units: Custom Service -

Understanding Doors & Windows for Cleanrooms Seals Solutions:

Understanding Doors & Windows for Cleanrooms Seals Solutions: -

Options for Doors in a Cleanroom: Which Type is Right for You?

Options for Doors in a Cleanroom: Which Type is Right for You? -

6 Considerations In Choosing Clean Room Doors

6 Considerations In Choosing Clean Room Doors -

Cleanroom Doors Sliding Doors: Which Is Best for Your Facility?

Cleanroom Doors Sliding Doors: Which Is Best for Your Facility? -

Choosing the Right Hygienic Doors for Your Facility

Choosing the Right Hygienic Doors for Your Facility -

Cleanroom Aluminum Profile Wholesale Market: Key Trends and Insights

Cleanroom Aluminum Profile Wholesale Market: Key Trends and Insights

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.

Speak Your Mind