Double Swing Door vs. Single: Which Fits Your Cleanroom Needs

- By:Lisa

- 2026-01-23

- 29

In the high-stakes world of sterile manufacturing and laboratory research, the humble door is much more than a simple point of entry. It is a critical component of your contamination control strategy. Facility managers and engineers often find themselves at a crossroads: which configuration truly optimizes their workflow while maintaining the strictest environmental integrity? E-ZONG suggests that while both have their place, the double swing door is often the unsung hero of high-throughput facilities.

Choosing between these two primary configurations isn't just about aesthetics; it’s about air changes, pressure differentials, and the daily ergonomics of your staff. This guide dives deep into the technical and operational nuances of cleanroom doors to help you make an informed investment.

The Strategic Importance of Door Selection

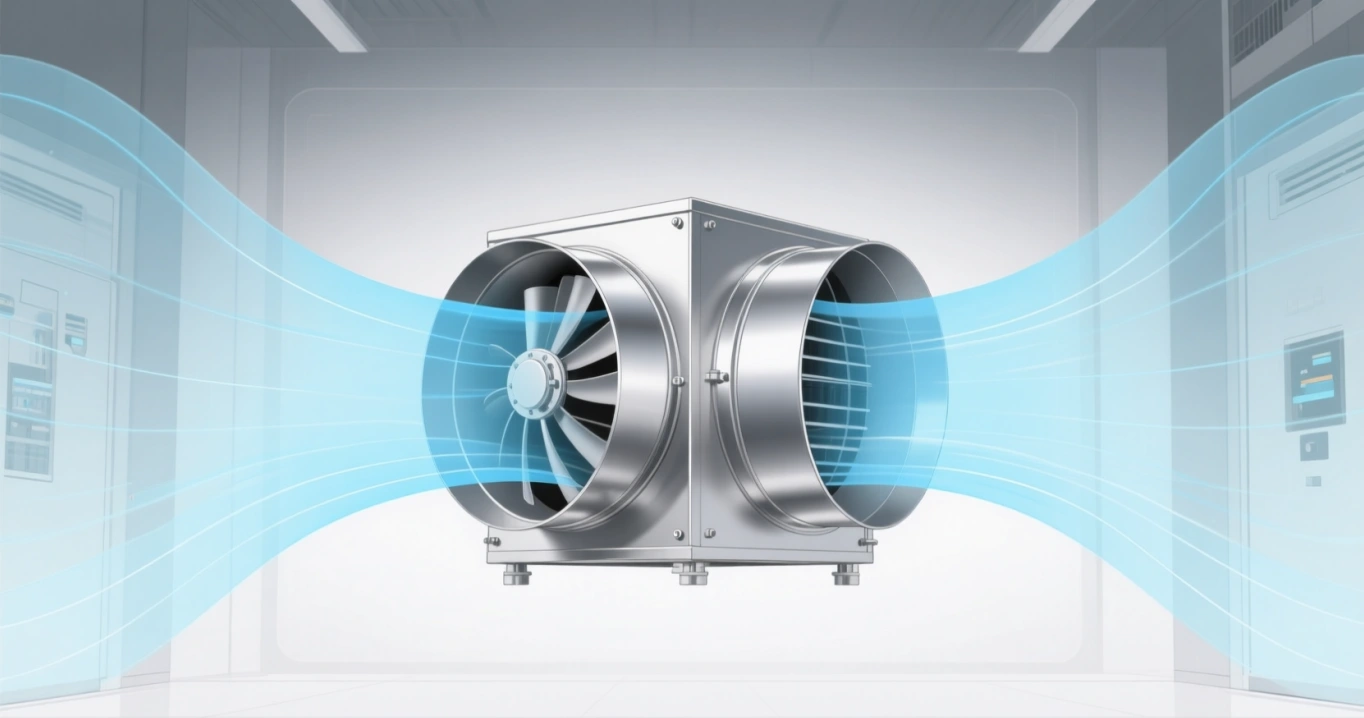

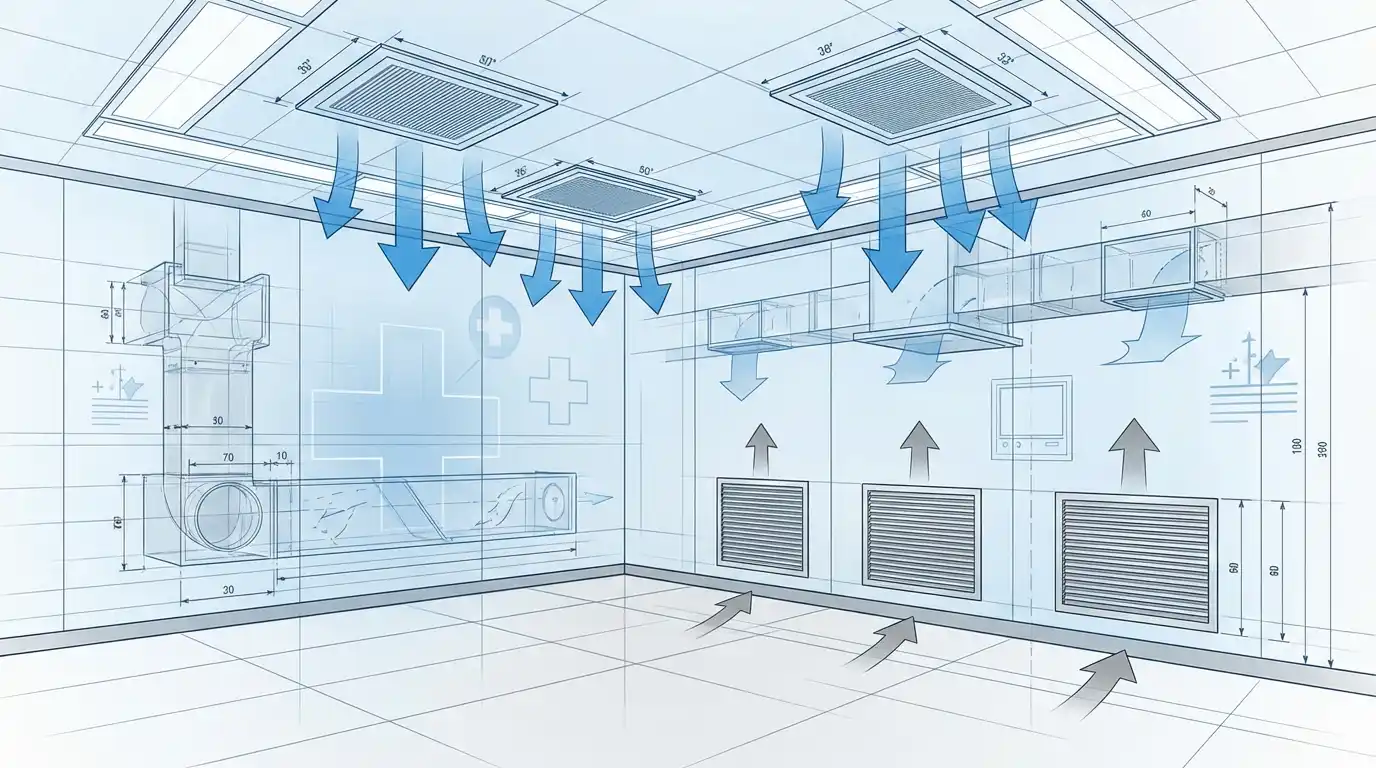

A cleanroom is a finely tuned machine where every variable—from the air handling units (AHU) to the flooring—must work in harmony. The doors represent the most frequent point of failure for pressure maintenance and the most likely source of cross-contamination.

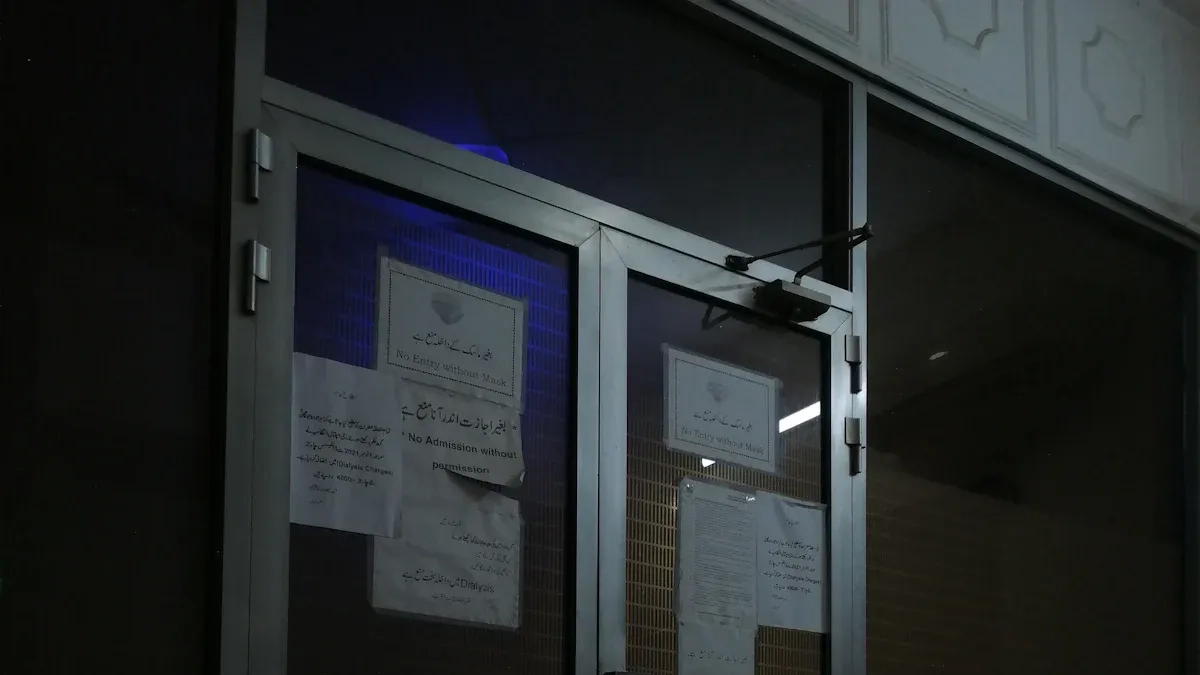

Whether you are operating an ISO 5 semiconductor plant or a GMP-compliant pharmaceutical suite, the transition between different pressure zones requires a door that balances speed with sealing. A double swing door offers a unique advantage in these environments by providing a wider aperture that can be operated with minimal physical contact, which is essential for maintaining hygiene.

Defining the Double Swing Door: Versatility at Scale

The double swing door consists of two panels that meet at a central point, allowing for a significantly larger opening than its single-panel counterpart. This design is engineered specifically for the dynamic nature of modern cleanrooms, where equipment is frequently moved and staff density can fluctuate throughout the day.

Mechanics of the Dual-Panel System

Unlike residential double doors, industrial cleanroom versions are designed with precision-engineered hinges that allow for 180-degree movement. This bidirectional flexibility means that a staff member pushing a heavy cart can simply move through the doorway without having to stop, pull, and turn. The "push-to-open" mechanics are a cornerstone of ergonomic facility design, often integrated with swing door leaf thickness 50mm to ensure maximum durability under heavy use.

Optimized Traffic Patterns for High-Throughput Zones

In facilities where every second counts, the double swing door minimizes bottlenecks. During shift changes or when large batches of supplies are being transferred, the ability for two panels to open simultaneously provides a clear path for personnel moving in opposite directions. This is particularly relevant in biopharmaceutical settings where "clean-in-place" or "move-in-place" equipment is standard.

Key Features of Dual-Panel Systems:

- Expansive Clearances: Ideal for pallets and large machinery.

- Bidirectional Operation: Enhances speed and safety.

- Symmetrical Design: Provides balanced airflow when both panels are engaged.

The Single Swing Door: Precision in Minimalist Design

The single swing door remains the industry standard for smaller, more specialized environments. It consists of one solid panel that swings in a single direction, providing a reliable and airtight seal that is easy to monitor and maintain.

Space-Saving Advantages in Laboratory Settings

In many R&D labs or micro-assembly areas, space is the most valuable commodity. A single panel requires a smaller "swing radius," meaning you can place workstations or sensitive analytical equipment closer to the entry point without risking a collision. For areas where visibility is as important as isolation, a half glass swing door is an ideal compromise.

Sealing Integrity and Pressure Containment

Because there is only one meeting point between the door and the frame (rather than two panels meeting in the middle), a single swing door can often achieve a slightly higher level of hermetic sealing with less complex hardware. For ultra-sensitive "mini-environments" where the air leakage rate must be near zero, the simplicity of a single panel is a significant benefit.

Key Features of Single-Panel Systems:

- Compact Footprint: Fits narrow corridors and small airlocks.

- Simplified Gasket Path: Easier to achieve a perfect seal around the perimeter.

- Cost-Effective: Lower hardware costs due to fewer moving parts.

Comparative Analysis: Door Types at a Glance

| Feature | Double Swing Door | Single Swing Door |

|---|---|---|

| Primary Use Case | High-traffic corridors / Equipment entry | Staff-only labs / Small utility rooms |

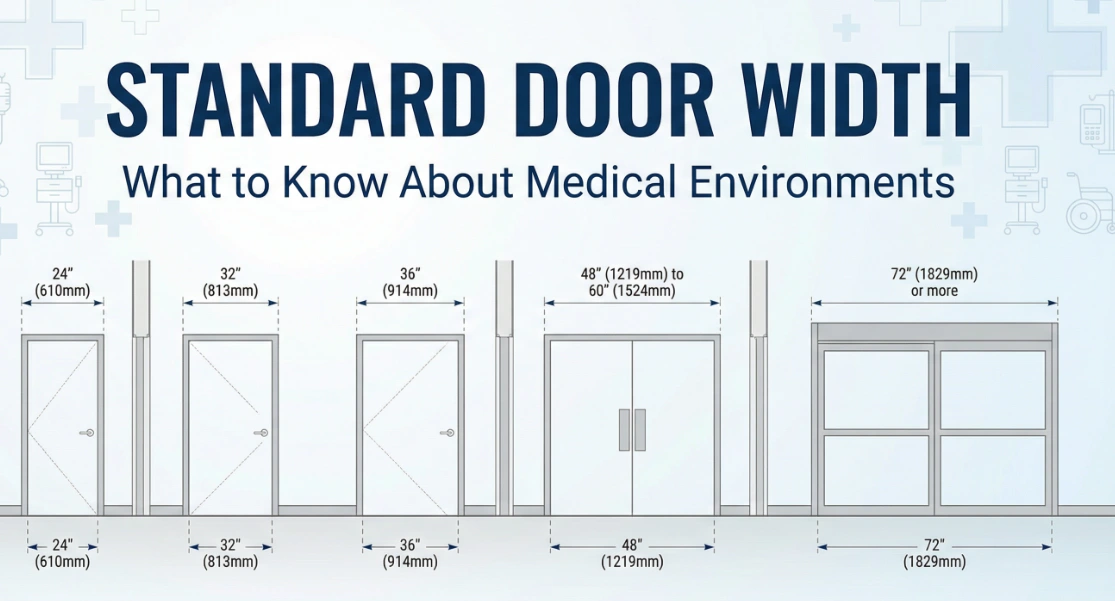

| Max Clearance | Up to 2000mm+ | Usually capped at 1000mm |

| Air Leakage Risk | Moderate (requires center seal) | Low (single perimeter seal) |

| Traffic Speed | Fast (bidirectional) | Slower (unidirectional) |

| ISO Compatibility | ISO 5 - ISO 8 | ISO 1 - ISO 8 |

Technical Comparison: Layout and Spatial Dynamics

When designing a cleanroom layout, the "arc of movement" is a critical safety consideration. You must account for the space required for the door to swing without striking personnel or equipment.

Space Needs for the Dual-Panel Configuration

A double swing door divides the total opening width between two panels. This means each individual panel has a shorter swing radius than a single door of the same total width. For example, a 1800mm opening with two 900mm panels requires less "depth" in the hallway to open than a massive 1200mm single door would. This makes the dual-panel system surprisingly effective in wider corridors where you need to move large items but cannot afford a deep swing into the room.

Space Needs for Single Swing Door

The single swing door is the king of the "corner entry." It is often tucked into the corner of a room, swinging against a wall to minimize its impact on the floor plan. However, managers must be careful to ensure that the door does not open into the path of the air handling unit’s supply diffusers, as this can disrupt the laminar flow.

Workflow Impact and Ergonomics

Consider the "hands-full" scenario. A researcher carrying a tray of sensitive samples prefers a double swing door that can be nudged open with a shoulder or an elbow. In contrast, a single swing door often requires a manual handle turn, which increases the risk of touch-contamination. Modern cleanrooms are increasingly moving toward automated swing doors or hands-free sensors to mitigate this risk.

Contamination Control: The Science of Sealing

The primary function of any cleanroom door is to act as a barrier against particulates, microbes, and pressure loss.

Airflow and Pressure Differentials

Cleanrooms rely on positive or negative air pressure to keep contaminants at bay. When a door opens, it creates a "pressure drop." A double swing door must be equipped with high-quality meeting stiles—the vertical edge where the two doors meet—to ensure that air doesn't whistle through the center gap. For more on how these components integrate with the wider HVAC system, see our guide on cleanroom doors mastering leakage and sealing tech.

Sealing and Particle Control

Particle emission from the door’s own hardware (hinges, latches) is a hidden danger. High-quality cleanroom doors use "flush-mount" designs where the hinges and glass observation windows are level with the door surface. This leaves no ledge for dust to accumulate. Whether you choose a single or dual-panel system, the materials must be non-shedding and resistant to the aggressive vapors used in VHP (Vaporized Hydrogen Peroxide) decontamination.

Cleaning and Maintenance Protocols

Sanitization is a daily reality. A double swing door has a more complex cleaning surface due to the center gap and the second set of hinges. However, when manufactured with smooth, medical-grade finishes, the time difference in cleaning is negligible.

- Daily: Wipe down handles and push plates with 70% IPA.

- Weekly: Inspect the bottom drop-seals for wear.

- Monthly: Check that the dual panels are still perfectly aligned to prevent center-seal gaps.

Material Science in Cleanroom Construction

What's inside your door is just as important as the surface. The durability of a double swing door depends heavily on its core and skin thickness.

Steel vs. Stainless Steel

Most B2B cleanroom projects opt for powder-coated galvanized steel or 304/316L stainless steel. Stainless steel is the gold standard for pharmaceutical environments because it withstands heavy moisture and chemical cleaning without rusting.

Core Materials: The Internal Integrity

- Aluminum Honeycomb: This is the preferred core for most high-tech cleanrooms. It is incredibly light, which reduces the strain on the hinges of a double swing door, yet it provides immense structural rigidity.

- Urethane Foam: Excellent for thermal insulation, often used in cold-room cleanrooms.

- Rockwool: Used when fire rating is the primary concern.

The 6mm Impact Advantage

In heavy industrial cleanrooms, carts and trolleys often bump into the doors. Some premium doors feature a reinforced outer skin or specialized internal reinforcements. Having a robust impact resistance ensures that the door doesn't dent; a dented door is a "dirty" door, as it creates a pocket where bacteria can grow.

Functionality and Access Control

Personnel Access and Emergency Egress

Safety regulations (such as NFPA or local fire codes) often dictate the size of doors required for emergency exits. A double swing door is frequently the designated fire exit for a cleanroom suite because it allows for the fastest mass evacuation. It can be fitted with "panic bars" that stay flush with the surface to maintain cleanroom standards while ensuring life safety compliance.

Equipment Movement and Logistics

If your facility involves "Modular Cleanroom" components that need periodic replacement, the dual-panel system is non-negotiable. Trying to squeeze a 1200mm-wide crate through a 900mm single door results in damaged door frames and compromised seals.

| Door Type | Best Suited for Equipment | Ease of Transit |

|---|---|---|

| Double Swing Door | Large bioreactors, conveyor belts | 10/10 |

| Single Swing Door | Small lab carts, handheld tools | 6/10 |

Compliance and Industry Standards

Navigating the regulatory landscape of ISO 14644 and GMP (Good Manufacturing Practice) is the most challenging part of facility management.

ISO 14644 and Air Leakage

ISO standards don't explicitly say "you must use a double swing door," but they do mandate specific air change rates and particle counts. If your door leaks air, your AHU has to work harder, increasing energy costs and the risk of a "failed" room.

GMP and Documentation

For FDA-regulated industries, every component in the cleanroom must have a paper trail. This includes:

- Material Certifications: Proving the steel and core are non-toxic.

- Air Leakage Tests: Quantifying the "hermetic" quality of the door.

- Fire Rating Certificates: Essential for insurance and safety.

E-ZONG provides a comprehensive documentation package with every installation, ensuring that when the auditors arrive, you have everything ready for a smooth inspection.

Common Selection Pitfalls to Avoid

- Undersizing the Door: Choosing a single swing door for an area that will eventually need to house large equipment.

- Ignoring the Swing Direction: Installing a door that swings into a narrow corridor, creating a safety hazard.

- Cheaping out on Hardware: A double swing door is only as good as its hinges. Low-quality hinges will sag over time, ruining the center seal.

Choosing the Right Door: A Decision Framework

To help you decide, we have categorized the most common cleanroom scenarios and provided our expert recommendation.

Scenario A: The High-Traffic Corridor

If your door connects a primary gowning room to the main production floor, the traffic will be constant.

- Recommendation: Double swing door.

- Why: It handles the volume of people and allows for bidirectional flow without "traffic jams."

- Checklist: Ensure it has large vision panels (observation windows) so staff can see if someone is coming from the other side.

Scenario B: The Small Analytic Lab

A quiet room with one or two technicians working on sensitive assays.

- Recommendation: Single swing door.

- Why: Space-saving and easier to maintain a perfect hermetic seal for ultra-stable air pressure.

- Checklist: Look for a flush-mount design to keep the small room feeling open and easy to clean.

Scenario C: The Air Pressure Sensitive Zone

An airlock or "bubble" pass-through where maintaining a 15-pascal pressure differential is critical.

- Recommendation: Custom Sealed Single or Double Door.

- Why: The sealing technology is more important than the door type here.

- Checklist: Focus on "interlocking" systems—where one door cannot open until the other is fully closed.

E-ZONG: Your Partner in Cleanroom Excellence

With over two decades of experience, E-ZONG has seen the evolution of cleanroom technology firsthand. We don't just sell doors; we provide solutions for contamination control. Our engineering team works with you from the planning stage to ensure that your double swing door or single swing door configuration is optimized for your specific ISO class.

Our Service Pillars:

- Planning & Design: We analyze your floor plan to suggest the most efficient door "arcs."

- Product Customization: From 6mm thick impact-resistant skins to specialized vision panel shapes.

- Compliance Consulting: We ensure every door meets the latest ISO and GMP guidelines, providing the documentation needed for successful audits.

FAQ

What is the main difference between a double swing door and a single swing door?

A double swing door has two panels that open from the center. A single swing door has one panel that opens one way. Double swing doors give wider access. Single swing doors save space.

How do cleanroom doors help control contamination?

Cleanroom doors use tight seals and smooth surfaces. These features block dust and germs. Staff can clean them easily. Good doors help keep the air clean and protect sensitive work.

Can both door types meet ISO and GMP standards?

Yes. Both double swing and single swing doors can meet ISO and GMP standards. The key is proper installation, regular cleaning, and using doors with strong seals. E-ZONG designs doors to support these requirements.

Which door is easier to maintain?

Single swing doors are simpler. They have fewer moving parts. This makes cleaning and repairs faster. Double swing doors need more checks because they have more hinges and panels.

When should a facility choose a double swing door?

A facility should pick a double swing door for busy areas. These doors help when staff move large carts or equipment. They also work well during shift changes or emergencies.

-

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment -

Top Aluminium Profile Manufacturers in China: Leading the Global Market

Top Aluminium Profile Manufacturers in China: Leading the Global Market -

The Evolution of Air Tight Sliding Doors

The Evolution of Air Tight Sliding Doors -

AHU Aluminium Profile: A Comprehensive Guide

AHU Aluminium Profile: A Comprehensive Guide -

The Importance of Choosing the Right Cleanroom Door in Vietnam

The Importance of Choosing the Right Cleanroom Door in Vietnam -

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety -

.jpg) The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities!

The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities! -

Unlock the Possibilities with AJ Manufacturing Doors

Unlock the Possibilities with AJ Manufacturing Doors -

Make a Statement with Manufactured Home Interior Doors!

Make a Statement with Manufactured Home Interior Doors! -

what is aluminum profile? Aluminum Profiles for Your Home is the best option

what is aluminum profile? Aluminum Profiles for Your Home is the best option

-

Steel vs. Glass Sealed Door for Modern Cleanroom Needs

Steel vs. Glass Sealed Door for Modern Cleanroom Needs -

Double Swing Door vs. Single: Which Fits Your Cleanroom Needs

Double Swing Door vs. Single: Which Fits Your Cleanroom Needs -

Unit Ventilator Explained: Meeting Modern HVAC Needs

Unit Ventilator Explained: Meeting Modern HVAC Needs -

Supply vs. Return HVAC Grilles: Healthcare Selection Guide

Supply vs. Return HVAC Grilles: Healthcare Selection Guide -

Linear Diffuser: The Secret to Modern HVAC Comfort & Design

Linear Diffuser: The Secret to Modern HVAC Comfort & Design -

What to Know About Standard Door Width in Medical Environments

What to Know About Standard Door Width in Medical Environments -

What Is a Return Air Vent and Why Does It Matter in HVAC

What Is a Return Air Vent and Why Does It Matter in HVAC -

Top Materials for Durable Pharma Clean Room Doors

Top Materials for Durable Pharma Clean Room Doors -

Hospital Cleanroom Door Design Requirements

Hospital Cleanroom Door Design Requirements -

Swing Doors vs Standard Doors: Which Is Right for Your Facility

Swing Doors vs Standard Doors: Which Is Right for Your Facility

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.

Speak Your Mind