Double Leaf Cleanroom Door Improves Workflow Efficiency in Medical Device Assembly Lines

- By:hqt

- 2025-05-26

- 29

Double Leaf Cleanroom Door plays a key role in modern assembly lines. It offers a smooth barrier between clean zones. Workers pass through without delays or contamination risks. The door's wide opening suits large equipment and team movement. Its reliable seals keep dust and particles out. This boosts product quality in medical device production.

More facilities are now replacing traditional single doors with double leaf options. Why? Because the design supports faster operations without sacrificing cleanliness. It's simple, reliable, and fits perfectly into strict cleanroom standards.

Whether you are managing a large production line or a small sterile lab, upgrading to a Double Leaf Cleanroom Door can make a big difference. In this article, we explore how this smart solution is helping medical device assembly lines work better and faster.

The Need for Smarter Cleanroom Solutions

Growing Demand in Medical Device Manufacturing

Medical device manufacturing is growing rapidly. More companies are building cleanrooms to ensure product safety and quality. These environments must meet strict hygiene and airflow standards. Doors play a key role in keeping these areas clean and efficient.

Importance of Cleanroom Workflow Efficiency

Workflow efficiency affects production speed and staff performance. If movement is blocked or delayed, operations slow down. A smooth entry and exit system helps avoid such delays. That's why door design matters in every cleanroom.

Enter the Double Leaf Cleanroom Door

The Double Leaf Cleanroom Door is an ideal solution. It allows wide access for both staff and large equipment. It reduces contact and lowers the risk of contamination. This door supports high-speed operations and keeps the cleanroom secure.

Core Benefits of the Double Leaf Cleanroom Door

Seamless Workflow for Personnel and Equipment

The Double Leaf Cleanroom Door opens wide, allowing people and tools to pass easily. This saves time and energy. There is less waiting, less crowding, and more space to move freely. Teams can work faster and with fewer stops.

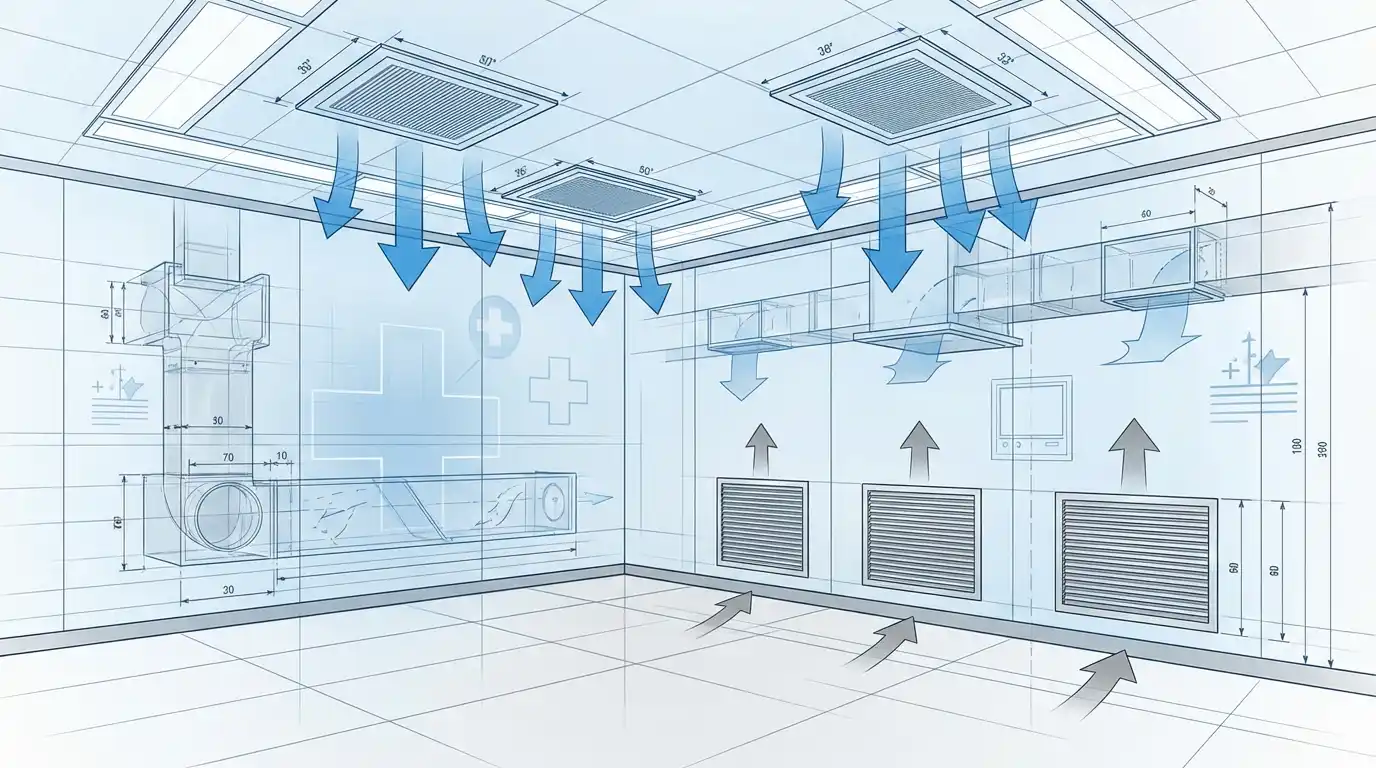

Enhanced Airtightness and Contamination Control

Air leaks can ruin a cleanroom. That's why airtight design is important. Our Double Leaf Cleanroom Door uses high-quality gaskets. These seals prevent outside air, dust, and particles from entering. This keeps the environment stable and clean.

Durable Design for High-Frequency Use

Cleanroom doors are opened many times a day. The Double Leaf Cleanroom Door is made for that. Its strong materials resist wear and cleaning chemicals. It stays in good shape, even after years of use. Maintenance is easy and cost-effective.

How Double Leaf Doors Transform Assembly Lines

Case Studies from Medical Device Facilities

Many companies have upgraded to the Double Leaf Cleanroom Door. In one medical device plant, switching to this door cut movement delays. Another site reported better control of airflow and fewer cleanroom breaches. These doors make a real difference.

Reduction in Production Downtime

Old doors can cause delays. They get stuck, don't seal well, or are too narrow. The Double Leaf Cleanroom Door solves these problems. With smooth operation and strong seals, downtime is reduced. This means more output and less stress for the team.

Improved Cleanroom Compliance and Safety

Safety and compliance are top priorities. The Double Leaf Cleanroom Door meets industry standards like GMP. Its rounded corners prevent injuries. Clear panels offer better visibility. Staff move safely and supervisors stay in control without opening the door.

Double Leaf Cleanroom Door by E-ZONG

GMP-Compliant, Easy-to-Clean Construction

Our Double Leaf Cleanroom Door is designed to meet GMP requirements. It is smooth and easy to clean. No dust or particles collect on the surface. This helps maintain hygiene inside the cleanroom. It is ideal for medical and food production environments.

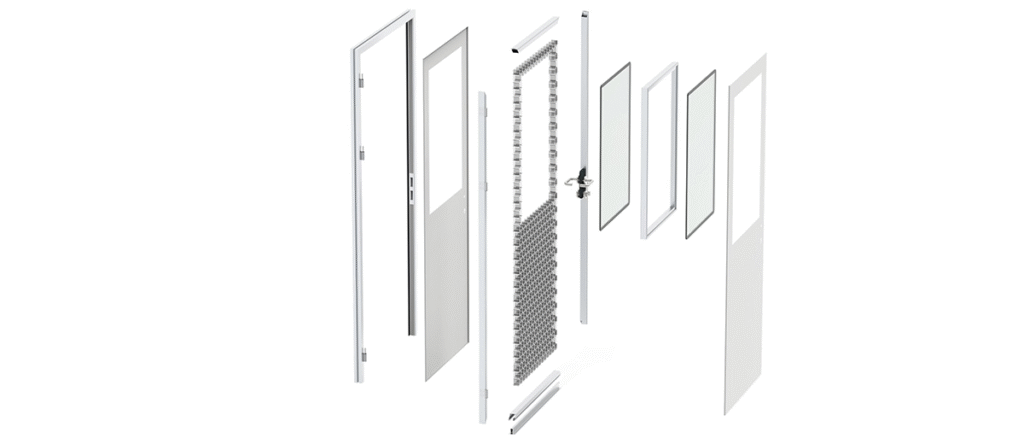

Advanced Sealing Gaskets for Airtight Protection

We use high-quality sealing gaskets in every Double Leaf Cleanroom Door. These gaskets create a strong seal when the door closes. This helps keep the air inside clean and prevents contamination. It also supports better airflow control inside the room.

Arc-Corner Design for Collision Safety

Safety is important in every cleanroom. Our Double Leaf Cleanroom Door has rounded arc corners. This reduces the chance of injury. The door is also impact-resistant and built to handle daily movement. It protects both people and equipment.

Half Glass Swing Door for Visibility and Control

Ideal for Supervision in Controlled Environments

The Half Glass Swing Door is perfect for areas that need observation. Its glass panel allows supervisors to see inside without opening the door. This helps monitor workflow while keeping the cleanroom sealed.

Food-Grade Coating with Anti-Fouling Performance

We use a food-grade surface coating on the Half Glass Swing Door. It is safe, non-toxic, and easy to clean. The anti-fouling surface keeps the door looking clean and professional, even with frequent use in demanding environments.

Flexible Sizes and Quick Installation

Each Half Glass Swing Door is available in different sizes. We design it to fit your specific layout. Installation is fast and simple. This helps reduce downtime during upgrades or renovations.

Why E-ZONG Leads the Cleanroom Door Market

27 Years of Experience and Innovation

At E-ZONG, we have over 27 years of experience in the cleanroom industry. We focus on making high-quality products like the Double Leaf Cleanroom Door and the Half Glass Swing Door. Our team is always looking for better ways to serve your needs.

Precision Engineering and Quality Materials

We use advanced production tools and follow strict quality control. Every Double Leaf Cleanroom Door we make is built to last. Our materials are strong, cleanroom-safe, and designed for long-term use. We care about every detail.

Trusted Supplier in South China's Cleanroom Industry

E-ZONG is based in Guangzhou and serves all of South China. Many cleanroom builders trust us as their long-term partner. We are proud to offer reliable products that meet the highest standards in medical, food, and electronic industries.

Closing: Elevate Your Cleanroom with E-ZONG's Proven Solutions

E-ZONG offers cleanroom doors designed to meet modern challenges. Our Double Leaf Cleanroom Door and Half Glass Swing Door help improve workflow, safety, and cleanliness. Each product is made for high performance and easy maintenance. We understand your industry's needs and deliver solutions that fit. With over 27 years of experience, E-ZONG is your trusted partner for cleanroom success. Choose E-ZONG—where efficiency and compliance go hand in hand.

-

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment

-

Top Aluminium Profile Manufacturers in China: Leading the Global Market

-

The Evolution of Air Tight Sliding Doors

-

AHU Aluminium Profile: A Comprehensive Guide

-

The Importance of Choosing the Right Cleanroom Door in Vietnam

-

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety

-

The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities!

-

Unlock the Possibilities with AJ Manufacturing Doors

-

Make a Statement with Manufactured Home Interior Doors!

-

what is aluminum profile? Aluminum Profiles for Your Home is the best option

-

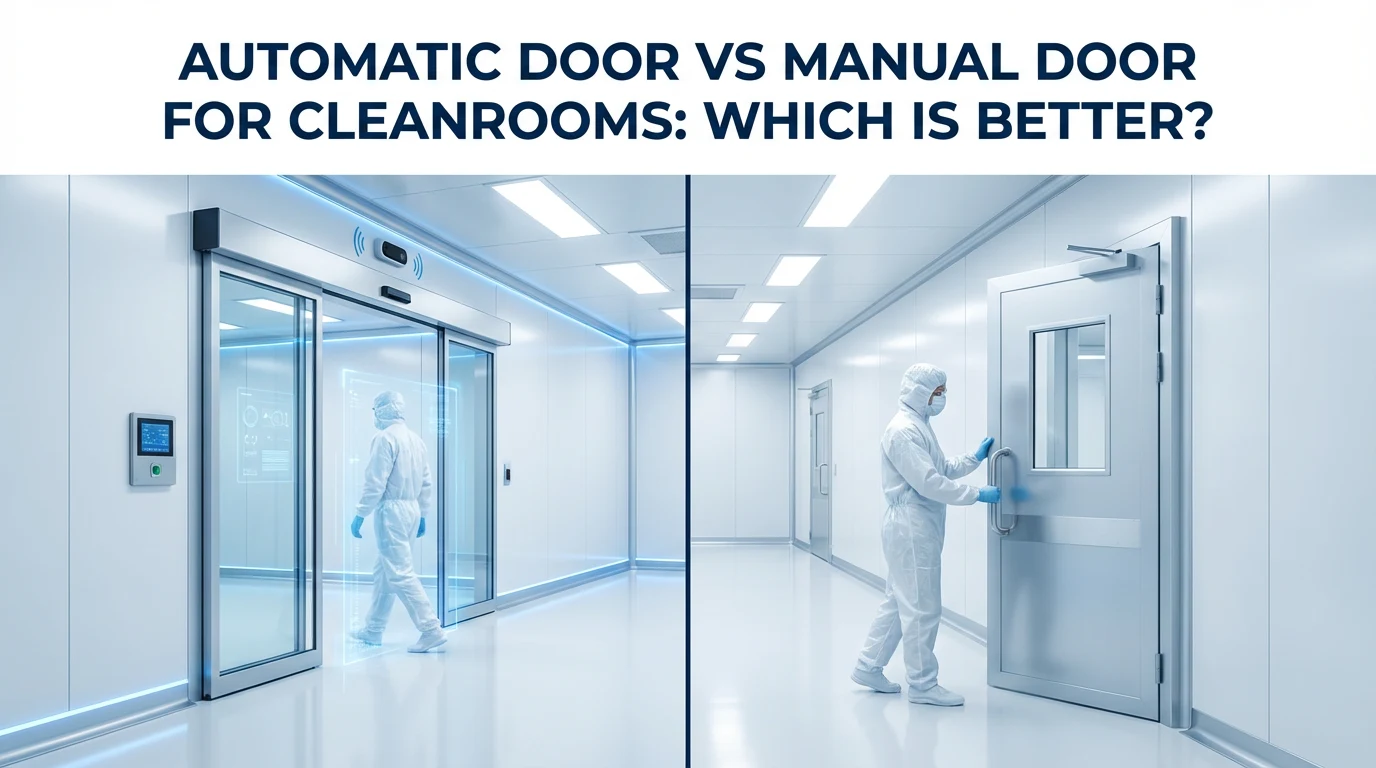

Automatic Door vs Manual Door for Cleanrooms: Which Is Better

-

Steel vs. Glass Sealed Door for Modern Cleanroom Needs

-

Double Swing Door vs. Single: Which Fits Your Cleanroom Needs

-

Unit Ventilator Explained: Meeting Modern HVAC Needs

-

Supply vs. Return HVAC Grilles: Healthcare Selection Guide

-

Linear Diffuser: The Secret to Modern HVAC Comfort & Design

-

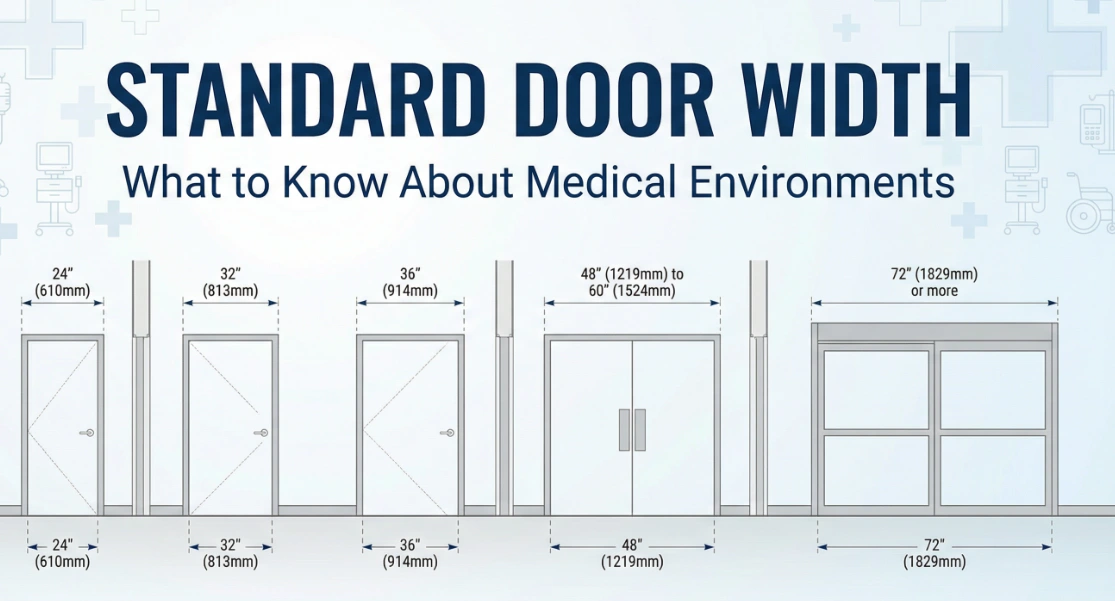

What to Know About Standard Door Width in Medical Environments

-

What Is a Return Air Vent and Why Does It Matter in HVAC

-

Top Materials for Durable Pharma Clean Room Doors

-

Hospital Cleanroom Door Design Requirements

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.

.jpg)

Speak Your Mind