Custom Floor Vent Solutions for Cleanroom Doors and Wall Systems

- By:Lisa

- 2025-09-30

- 29

Seamless Integration, Precision Airflow, and Compliance in Critical Environments

The Strategic Role of Floor Vents in Modern Cleanroom Design

In pharmaceutical, biotech, semiconductor, and healthcare facilities, maintaining air cleanliness isn’t optional—it’s foundational. ISO 14644-1 classifies cleanrooms from ISO Class 1 to Class 9, with performance hinging on stable, unidirectional airflow. At floor level, the floor vent serves as a critical interface for return air, directly influencing pressure control, particle removal, and regulatory compliance.

Yet standard floor vents often fail in high-performance environments—especially near automatic doors or modular wall systems—where gaps, protrusions, or poor airflow design create contamination risks. This is why custom floor vent solutions have become essential in advanced cleanroom projects.

This article explores how precision-engineered floor vents can be seamlessly integrated with cleanroom architecture to ensure performance, compliance, and long-term reliability.

Unique Engineering Challenges at the Door-Wall-Floor Interface

Spatial Conflicts During Installation

Automatic or airtight swing doors often house motors or sensors within the bottom 30–60 mm of the frame. Standard floor vents, typically only 25–40 mm tall, cannot fit without compromising wall integrity or protruding above finished flooring—creating tripping hazards and obstructing automated cleaning equipment.

Airflow Disturbance from Door Operation

Per ASHRAE, a single automatic door cycle can introduce 30–50 m³/h of uncontrolled air in under 0.5 seconds. When floor air vents are positioned too close to the door threshold, this transient pressure drop creates vortices that pull contaminants into the return path—undermining laminar flow.

Leakage Through Gaps

GB 50333-2013 requires a dynamic pressure differential of at least 2.5 Pa in operating rooms. Yet a 1-mm gap spanning 1 meter can leak ~12 m³/h at 8 Pa—enough to destabilize room pressurization. Standard floor vents rarely seal perfectly against door frames, creating hidden leakage paths.

Cleaning Dead Zones

China’s GMP guidelines require equipment to be “easy to clean and free of hygiene dead zones.” Protruding floor vents trap particles and microbes, frequently triggering FDA 483 observations.

Core Design Principles for High-Performance Custom Floor Vents

Material Selection: Aluminum vs. Stainless Steel

While stainless steel floor vent units offer strength, they are heavy, prone to condensation, and costly. In contrast, aluminum floor grille systems—fabricated from high-purity 6063-T5 alloy—deliver superior performance:

- Impurity content <0.35% ensures zero particle shedding

- Surface roughness Ra ≤ 0.8 μm meets ISO 14644-4

- Anodized finishes provide exceptional corrosion resistance

Flush-Mount Installation for Seamless Integration

The flush mount floor vent is now a benchmark in modern cleanroom design:

- Perfectly level with epoxy or PVC flooring (±0.5 mm tolerance)

- Rounded edges prevent snagging during cleaning

- Tool-free grilles enable rapid maintenance

Field data shows flush mount floor vent installations increase automated scrubber coverage from 82% to 99%.

Airflow Optimization Beyond Passive Openings

A high-performance floor return vent cover isn’t just a cover—it’s an active airflow management device:

- Adjustable dampers allow ±15% fine-tuning of return volume

- Micro-perforated patterns reduce face velocity to 1.5–2.5 m/s, minimizing turbulence

- CFD-validated designs ensure airflow uniformity within ±10% across the critical zone

Deep Integration with Cleanroom Door Systems

Advanced custom HVAC return grille units are engineered to work in concert with automatic doors:

- Pre-coordinated cutouts align with door bottom seals

- Dual-seal design prevents short-circuiting

- Integrated conduit channels support pressure or airflow sensors for BMS connectivity

Compliance and Certification Requirements

Every HVAC floor return grille must satisfy:

- ISO 14644-4: Surfaces must be smooth and non-shedding

- China GMP (2010): Equipment must be “easy to clean and corrosion-resistant”

- GB 50333-2013: Return grilles must eliminate dust traps

Reputable suppliers provide material certificates, particle-shedding test reports (per IEST-RP-CC021.3), and performance curves for HVAC return vent units.

Industry-Specific Applications

Pharmaceutical & Biotech Cleanrooms

In ISO Class 5 zones, custom floor vent units feature ≤1.0 mm perforations and Ra ≤ 0.4 μm surfaces. One vaccine manufacturer saw Grade A particle compliance rise from 92% to 99.6% after implementation.

Hospital Operating Rooms & Isolation Wards

Flush mount floor vent systems integrated with automatic doors maintain dynamic pressure differentials ≥2.8 Pa—critical for JCI accreditation. In negative-pressure rooms, HVAC return vent units with real-time feedback ensure rapid pressure stabilization.

Semiconductor & Electronics Manufacturing

Class 1–100 environments demand aluminum floor grille units with ultra-high purity and electrostatic dissipation. A 12-inch wafer fab reported a 60% drop in photolithography particle excursions after upgrading.

Modular & Prefab Cleanrooms

Easy clean floor vent modules are factory-assembled with wall panels, enabling “plug-and-play” field installation—cutting on-site labor by 30–50%.

Case Study: Operating Room Retrofit in a Tier-3 Hospital

Challenge: Upgrade six ISO Class 5 operating rooms while retaining existing automatic doors. Limited 35 mm clearance under door frames; existing PVC flooring could not be altered.

Solution:

- L-shaped custom HVAC return grille embedded into door frame recess

- Brushed anodized finish matching wall panels

- Quick-release floor return vent cover for filter access

- Sensor conduit integrated for BMS connection

Results:

- Static pressure: 8.2 Pa; dynamic minimum: 2.8 Pa

- Full compliance with JCI standards

- Filter replacement time reduced from 20 minutes to 3 minutes

Conclusion: From Component to System Enabler

The floor vent has evolved from a passive duct termination into a mission-critical system component. In high-stakes environments, choosing a partner with proven expertise in custom floor vent design, flush mount floor vent integration, and aluminum floor grille manufacturing ensures long-term compliance and operational resilience.

Looking ahead, next-generation easy clean floor vent systems will incorporate smart sensing and adaptive airflow control—transforming cleanrooms into dynamic, responsive environments.

-

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment -

Top Aluminium Profile Manufacturers in China: Leading the Global Market

Top Aluminium Profile Manufacturers in China: Leading the Global Market -

The Evolution of Air Tight Sliding Doors

The Evolution of Air Tight Sliding Doors -

AHU Aluminium Profile: A Comprehensive Guide

AHU Aluminium Profile: A Comprehensive Guide -

The Importance of Choosing the Right Cleanroom Door in Vietnam

The Importance of Choosing the Right Cleanroom Door in Vietnam -

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety -

.jpg) The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities!

The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities! -

Unlock the Possibilities with AJ Manufacturing Doors

Unlock the Possibilities with AJ Manufacturing Doors -

Make a Statement with Manufactured Home Interior Doors!

Make a Statement with Manufactured Home Interior Doors! -

what is aluminum profile? Aluminum Profiles for Your Home is the best option

what is aluminum profile? Aluminum Profiles for Your Home is the best option

-

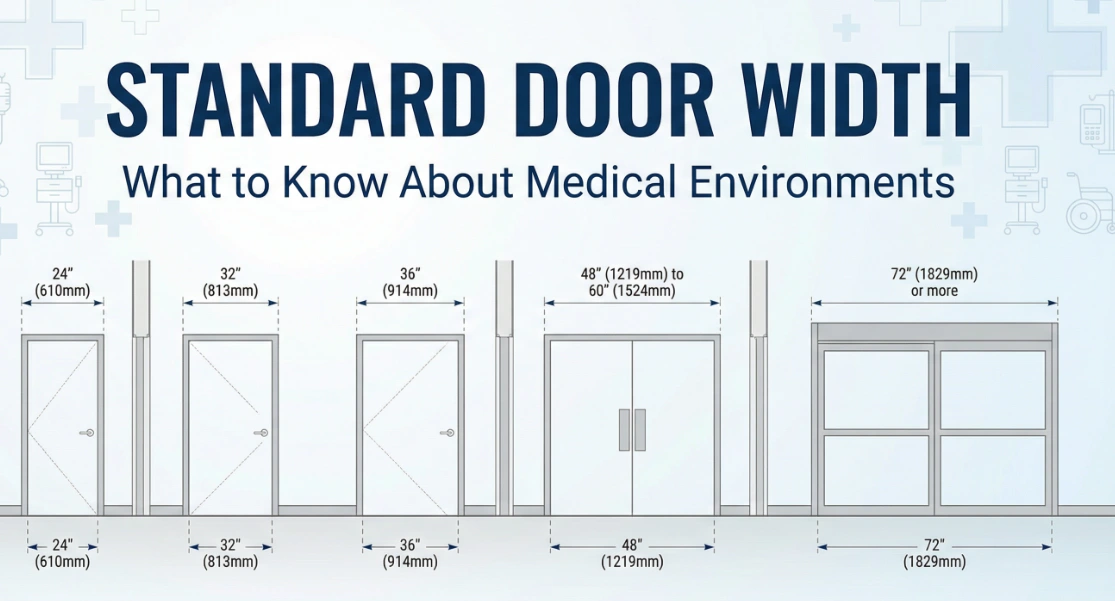

What to Know About Standard Door Width in Medical Environments

What to Know About Standard Door Width in Medical Environments -

What Is a Return Air Vent and Why Does It Matter in HVAC

What Is a Return Air Vent and Why Does It Matter in HVAC -

Top Materials for Durable Pharma Clean Room Doors

Top Materials for Durable Pharma Clean Room Doors -

Hospital Cleanroom Door Design Requirements

Hospital Cleanroom Door Design Requirements -

Swing Doors vs Standard Doors: Which Is Right for Your Facility

Swing Doors vs Standard Doors: Which Is Right for Your Facility -

Cleanroom Door Materials Explained: Key Types and Applications

Cleanroom Door Materials Explained: Key Types and Applications -

How Do Different Vent Grills Impact Medical Cleanrooms

How Do Different Vent Grills Impact Medical Cleanrooms -

Controlled Environment vs Air Clean Room Differences Explained

Controlled Environment vs Air Clean Room Differences Explained -

How to Extend the Life of Your Exterior Steel Door

How to Extend the Life of Your Exterior Steel Door -

What Are the Best Materials for AC Vent Covers

What Are the Best Materials for AC Vent Covers

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.

Speak Your Mind