Cleanroom Air Diffuser? Get the Aluminum Frame Right

- By:Lisa

- 2025-09-09

- 29

In high-precision industries—advanced manufacturing, biopharmaceuticals, microelectronics packaging—where environmental control demands near-perfection, cleanrooms are no longer mere “dust-free chambers.” They are sophisticated environmental ecosystems with full “vital signs.” At their core lies the air handling and airflow organization system, often referred to by engineers as the “respiratory system”: it “inhales” multi-stage filtered fresh air, “exhales” contaminated return air, and simultaneously maintains temperature, humidity, pressure differentials, and particulate concentrations within tightly controlled thresholds. Supporting this “respiratory system” to operate efficiently, stably, and reproducibly? That’s the job of the structural skeleton built from industrial aluminum profiles.

What Exactly Is an Air Diffuser? — From Functional Definition to Engineering Implementation

Before diving into structural details, we must clarify one core concept: What is an air diffuser?

An air diffuser (also called a ceiling air diffuser, HVAC diffuser, or supply air diffuser) is a terminal device in HVAC systems designed to precisely control the direction, velocity, and distribution pattern of airflow. It’s far more than just an “outlet.” Through carefully engineered geometries—such as linear slots, perforated plates, nozzles, or swirl vanes—it transforms high-velocity, concentrated jets into low-velocity, uniform flows, enabling targeted contaminant removal and even temperature/humidity distribution.

So, what does an air diffuser actually do? It fulfills three primary functions:

- Flow Pattern Control — Dictates whether airflow is laminar, turbulent, or displacement-based.

- Velocity Uniformity — Prevents localized eddies or stagnant zones.

- Pressure Gradient Maintenance — Works with return air diffusers to isolate zones.

In cleanrooms, air diffusers are often integrated with HEPA/ULPA filters to form “filter + diffuser” units—like FFUs (Fan Filter Units) or MAUs (Modular Air Handling Units). Their installation precision, sealing performance, and structural rigidity directly determine whether cleanliness targets can be met.

Core Aerodynamic Elements in Cleanroom Design

The supply air diffuser serves as the terminal actuator of the “respiratory system.” Its role isn’t merely to deliver air—it’s to master flow pattern control and contaminant removal efficiency. Per ISO 14644-4, cleanroom airflow patterns fall into two categories: unidirectional flow (commonly called “laminar flow”) and non-unidirectional flow (“turbulent flow”). The former requires airflow velocities of 0.3–0.5 m/s with directional deviations ≤15° (vertical or horizontal); the latter relies on dilution and air change rates (typically 20–60 ACH) to manage contamination.

Regardless of the mode, the flatness of the diffuser mounting plane, structural rigidity, and sealing integrity critically impact airflow uniformity and vortex suppression. Experimental data shows that if surface flatness deviates beyond ±1mm, local airflow velocity can fluctuate by ±15%, disrupting particle settling paths and degrading cleanliness by 1–2 ISO classes (e.g., ISO 5 → ISO 6).

Moreover, HEPA (H13–H14) and ULPA (U15–U17) filters—the heart of the diffuser assembly—depend on frame sealing integrity, which in turn relies on the dimensional precision of the supporting profile frame. EN1886 mandates that filter housings deform ≤3mm/m under 1500Pa static pressure; otherwise, edge leakage exceeds acceptable limits (Class B requires <0.01% leakage). This rigidity requirement is precisely what aluminum profiles—through optimized cross-sections and alloy strengthening—can reliably deliver.

Structural Material Constraints Imposed by HVAC Subsystems

A cleanroom’s “respiratory system” comprises multiple subsystems: supply plenums, air diffuser arrays, return air plenums, exhaust ducts, and pressure control valve banks. Each imposes specific demands on the supporting structure:

- Supply Plenum: Must remain dimensionally stable under 500–1500Pa static pressure, with smooth interior surfaces (Ra ≤0.8μm) to minimize turbulence and zero outgassing to prevent TVOC contamination.

- Return Air Pathways: Must maintain negative pressure gradients (typically 5–15Pa), be easy to clean and validate (CIP/SIP compatible), and avoid dust traps. Often employs return air diffusers or ventilation diffusers designed to diffuse airflow—not just exhaust it.

- Suspension Systems: Must be lightweight (to reduce floor loading), high specific strength, and vibration-damping (isolate 10–50Hz fan vibrations).

Traditional carbon steel or stainless steel, while strong, suffer from excessive weight, corrosion risk, complex surface treatments, and high thermal conductivity. Industrial aluminum profiles—with their lightweight strength, corrosion resistance, ease of fabrication, and low outgassing—have emerged as the material of choice for cleanroom structural systems.

Material Engineering Advantages of Aluminum Profiles: Why They Dominate Cleanroom Structures

Physical and Chemical Performance Comparison

In cleanroom material selection, aluminum profiles aren’t a compromise—they’re the optimal solution after rigorous performance benchmarking. Below is a comparison of key parameters under cleanroom conditions:

| PERFORMANCE METRIC | 6063-T5 ALUMINUM PROFILE | 304 STAINLESS STEEL | HOT-DIP GALVANIZED STEEL |

|---|---|---|---|

| Density (g/cm³) | 2.7 | 7.9 | 7.85 |

| Tensile Strength (MPa) | 160 | 520 | 370 |

| Specific Strength | 59.3 | 65.8 | 47.1 |

| Surface Roughness Ra (μm) | 0.2–0.4 (anodized) | 0.4–0.8 (polished) | 1.6–3.2 (galvanized) |

| IPA Wipe Resistance (5000x) | No corrosion/discoloration | No corrosion | Coating blisters, rust |

| Thermal Expansion (×10⁻⁶/℃) | 23.6 | 17.3 | 11.7 |

| Thermal Conductivity (W/m·K) | 201 | 16.3 | 51.9 |

Clearly, aluminum excels in lightweighting, surface smoothness, and chemical resistance. Especially in biopharmaceutical cleanrooms requiring frequent IPA, NaClO, or H₂O₂ disinfection, anodized aluminum withstands pH 3–10 cleaners without degradation. Stainless steel, while corrosion-resistant, is costly to polish and can shed “stainless fines”—a hidden particle source.

How Surface Treatments Impact Cleanliness

Aluminum’s cleanroom suitability hinges on precision surface treatments:

- Anodizing: Forms a hard Al₂O₃ layer (10–25μm thick, per AA10–AA25 standards). Hardness up to HV400, salt spray resistance ≥1000 hrs, particle release <10 particles/cm² (per IEST-RP-CC031.1). Ideal for electronics and pharma.

- Electrophoretic Coating: Organic coating deposited via DC field (15–25μm thick). Excellent alkali resistance (pH 12, 72h stable). Suited for high-humidity or CIP/SIP zones.

- PVDF Fluorocarbon Coating: Superior weather and chemical resistance. Withstands HF and other aggressive agents. Used in specialty chemical environments.

Surface roughness (Ra) directly affects dust accumulation. Tests show Ra >0.8μm increases particle adhesion by 3x. Precision-drawn and treated aluminum profiles maintain Ra <0.4μm—far smoother than galvanized steel (>1.6μm)—dramatically reducing cleaning effort and microbial risk.

How to clean air diffusers? Gently wipe with lint-free cloth soaked in 75% IPA. Avoid silicone-, fluorine-, or abrasive-based cleaners—they damage anodized layers or introduce new contaminants. Post-cleaning, perform particle release testing (IEST-RP-CC031.1) to verify cleanliness recovery.

Structural Mechanics Tailored to Cleanroom Demands

Cleanroom structures must maintain geometric stability under static loads, thermal stress, and vibration. Aluminum profiles, through intelligent cross-sections (I-beams, box sections, stiffeners), achieve high moment of inertia (Ix) to resist bending.

Typical FFU ceiling support beam: 60×40mm, 3mm wall thickness, Ix=125,000 mm⁴. Under 1.2m span and 200N/m uniform load (FFU + filter), max deflection δ=0.8mm (<L/1500), compliant with GB 50591-2010.

Connection strength is equally critical. Standard T-nut + hex bolt systems offer ≥2.5kN pull-out resistance per point, meeting seismic Zone 8 (0.2g) requirements. Vibration tests (10–50Hz, 0.3g acceleration) show displacement <0.1mm—preserving diffuser seal integrity.

Five Structural Roles of Aluminum Profiles in Cleanroom HVAC Systems

1. Supply Plenum Frame System — The Backbone for Ceiling Air Diffusers

The supply plenum acts as the “pressure-stabilizing chamber” upstream of air diffusers, converting turbulent, high-speed flow into uniform, low-speed flow before HEPA/ULPA filtration. Aluminum profiles here serve dual roles: rigid skeleton + sealing base.

Typical structure: 60×40mm T-slot main beams, 40×40mm square tube cross members, forming a grid. HEPA filter frames slot into T-slots, sealed with EPDM gaskets. Side panels: 5mm anodized aluminum, riveted in place.

Key design specs:

- Internal static pressure: 800–1200Pa (ensures flow uniformity)

- Frame deformation: <1.5mm/m (EN1886 Class B)

- Airflow uniformity: ±5% (per ANSI/ASHRAE 110)

- Leakage rate: <0.01% (smoke test verified)

In a 12-inch wafer fab, a plenum built with 6061-T6 high-strength aluminum showed only 0.8mm/3m deformation after 3 years—zero filter leakage, particle levels stable at ISO Class 3.

The ceiling air diffusers here use plug-in designs, enabling tool-free, rapid replacement—ideal for commercial diffusers or hospitality-grade units requiring frequent maintenance.

2. Return Wall/Column System — Structural Carrier for Return Air Diffusers

The return system is the “exhalation channel” of the respiratory system. Aluminum-built return walls/columns must offer smooth interiors, adjustable porosity, and easy maintenance.

Structure: 80×40mm uprights with guide rails, 50×30mm cross beams, perforated aluminum panels (Φ6mm holes, 60% open area). Interior anodized to Ra=0.3μm, withstands >500 VHP sterilization cycles without corrosion.

Airflow optimization: Panels tilted inward 5° to guide smooth airflow entry. CFD simulations show 40% reduction in eddy zones. Adjustable louvers at base balance return airflow, maintaining pressure differentials within ±1Pa.

In a vaccine filling suite, return diffusers integrate particle sensors—real-time data feeds to BMS for dynamic airflow adjustment, stabilizing ISO 5 (Grade A) conditions.

3. Duct Suspension & Seismic Bracing — Load-Bearing Base for Duct-Mounted Diffusers

Ductwork is the “trachea” of the system. Aluminum suspension systems outperform traditional steel with lightweighting, dust-free assembly, and field adjustability.

Components: M8 aluminum hangers + chloroprene rubber pads (60 Shore A hardness), natural frequency >15Hz—effectively isolating fan vibrations (typically 25–35Hz). Rods: Φ12 solid aluminum, anodized, tensile strength ≥180MPa.

Adjustability: Threaded height adjustment (±50mm range) for BIM model alignment. Expansion joints every 10m compensate for thermal growth (ΔL=α·ΔT·L, α=23.6×10⁻⁶/℃).

Load rating: 80kg per hanger (including 1.4 dynamic factor), safety factor ≥3.0. In a data center cleanroom, aluminum hangers supported a 1.2-ton MAU for 3 years—zero loosening, vibration <1.8mm/s (per ISO 10816-3).

Widely used to suspend duct-mounted diffusers, especially in non-unidirectional zones where mounting precision directly affects airflow uniformity.

4. Equipment Platforms & Maintenance Walkways — Operational Backbone for Commercial Diffusers

HVAC equipment (fans, valves, sensors) demands regular access. Aluminum platforms/walkways must deliver load capacity, slip resistance, safety, and cleanliness.

Structure: 6063-T6 80×60mm main beams, 30×3mm anti-slip grating (EN14121 Class 3), 100mm toe-kick plates. Uniform load: 5kN/m² (~500kg/m²); point load: 2kN (tools + technician).

Safety: Φ32 handrails, hidden hex fasteners (no exposed sharp edges). Scratch-resistant anodized finish (Ra=0.5μm), withstands repeated 75% ethanol wiping.

In an antibody drug production suite, integrated cable trays and pneumatic line brackets reduced maintenance time by 30% and minimized human contamination risk—especially valuable in high-risk zones requiring frequent plug-in diffuser replacement.

5. Airtight Door Frames & Pass-Through Integration — Sealing Platform for Diffuser Grilles

Airtight doors and pass-throughs are critical pressure barriers. Aluminum’s dimensional precision and surface consistency make it ideal for door frames.

Frame design: Dual-chamber profile with embedded EPDM gasket grooves. 30% compression yields ≥2N/mm contact pressure. CNC-machined corners (R≥3mm) prevent airflow separation and eddies.

Interlock integration: Pre-tapped M12×1.5 holes for pressure sensors, electromagnetic locks, position switches. Leakage rate <0.1 m³/h·m when closed (per ISO 14644-4).

In a gene therapy cleanroom, pass-through frames integrated RFID readers and UV-C lamp mounts—no drilled holes, no seal compromise. Post-sterilization particle recovery <5 minutes. Diffuser grilles here feature removable designs for easy cleaning validation and part replacement.

Key Design & Selection Specifications

Profile Cross-Section Design: Mandatory Engineering Standards

Cleanroom structural design must comply with:

- ISO 14644-4: Materials must not become particle sources (test per IEST-RP-CC031.1).

- GB 50591-2010: Structural deflection ≤L/500; connections must remain tight.

- IEST-RP-CC031.3: Outgassing (TVOC) <1μg/cm²·h (tested at 23°C/50%RH/24h).

Cross-sections require FEA validation under combined loads: max static pressure (1500Pa) + equipment weight + thermal stress (ΔT=30°C). Recommended alloys: 6063-T5 or 6061-T6 (yield strength ≥150MPa).

Connection System Cleanliness Controls

Fasteners are potential contamination sources—select carefully:

- Bolts/Nuts: A2-70 stainless or matching aluminum (avoid galvanic corrosion).

- Thread Sealants: Use PTFE tape or Loctite 243 anaerobic sealant—never silicone (outgasses).

- Installation: Prefer T-nuts + hex bolts for “no exposed fasteners,” minimizing cleaning dead zones.

Torque control: M8 bolts at 25N·m, calibrated with digital torque wrench—prevents over-tightening (deformation) or under-tightening (vibration loosening).

Thermal & Vibration Compatibility Design

Thermal bridging and vibration transmission are silent killers:

- Thermal Breaks: Insert nylon spacers (λ=0.25W/m·K) at insulation penetrations to reduce condensation and energy loss.

- Vibration Isolation: Use chloroprene mounts (dynamic stiffness <500N/mm, transmissibility <10% at 10–50Hz).

- Thermal Expansion Compensation: Install expansion joints every 10m, allowing ΔL=7mm (for ΔT=30°C) to prevent stress buildup.

Real-World Failure Cases & Engineering Solutions

Case 1: Profile Warping → FFU Seal Failure

Project: Semiconductor packaging fab, ISO 5 cleanroom, 6063-T5 aluminum FFU ceiling.

Failure: Particle counts spiked after 6 months. Smoke test revealed HEPA frame leakage.

Data: Laser scan showed 3.2mm mid-span sag—exceeding EN1886 Class B limit (3mm/m).

Root Cause: Material creep—6063-T5 exhibits ~0.15% strain/year at 35°C, causing slow deformation under static pressure.

Solution:

- Upgrade to 6061-T6 (40% better creep resistance)

- Add longitudinal stiffeners (spacing reduced from 1200mm to 600mm)

- Install diagonal bracing inside plenum for triangular stability

Result: After 1 year, deformation <0.5mm, leakage <0.005%.

Case 2: Surface Corrosion → Particle Contamination

Project: Cell therapy lab, anodized aluminum return diffusers.

Failure: White powder appeared post-VHP sterilization; particle alarms triggered.

Data: EDS identified AlF₃—corrosion from trace HF in cleaning agents.

Root Cause: Anodized layer pitted and flaked under HF exposure.

Solution:

- Switch to PVDF fluorocarbon coating (25μm thick, withstands 5% HF for 24h)

- Reformulate cleaners—eliminate fluorine-containing ingredients

- Add post-sterilization rinse cycle (3x DI water flushes)

Result: Particle release dropped from 120 to <5 particles/cm².

Case 3: Loose Connections → Airflow Short-Circuiting

Project: Aseptic fill-finish suite, standard nut fasteners on ceiling hangers.

Failure: Pressure swings ±8Pa, laminar flow disrupted, particle counts exceeded limits.

Data: Vibration tests showed 0.3mm joint displacement (>0.1mm allowable).

Root Cause: Fan vibration loosened nuts, shifting plenum and breaking diffuser seals.

Solution:

- Replace with DIN 6796 Belleville washers for constant preload

- Torque M8 bolts to 25N·m + apply red anti-loosening marks

- Add lateral bracing to form spatial truss structure

Result: Pressure stabilized to ±1Pa; airflow uniformity restored to ±3%.

Aluminum profiles don’t just support cleanrooms—they breathe life into them. Precision-engineered, chemically resilient, and mechanically intelligent, they’re the silent architects of contamination control. In the high-stakes world of clean environments, the right skeleton doesn’t just hold things up—it holds standards up.

-

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment -

Top Aluminium Profile Manufacturers in China: Leading the Global Market

Top Aluminium Profile Manufacturers in China: Leading the Global Market -

The Evolution of Air Tight Sliding Doors

The Evolution of Air Tight Sliding Doors -

AHU Aluminium Profile: A Comprehensive Guide

AHU Aluminium Profile: A Comprehensive Guide -

The Importance of Choosing the Right Cleanroom Door in Vietnam

The Importance of Choosing the Right Cleanroom Door in Vietnam -

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety -

.jpg) The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities!

The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities! -

Unlock the Possibilities with AJ Manufacturing Doors

Unlock the Possibilities with AJ Manufacturing Doors -

Make a Statement with Manufactured Home Interior Doors!

Make a Statement with Manufactured Home Interior Doors! -

what is aluminum profile? Aluminum Profiles for Your Home is the best option

what is aluminum profile? Aluminum Profiles for Your Home is the best option

-

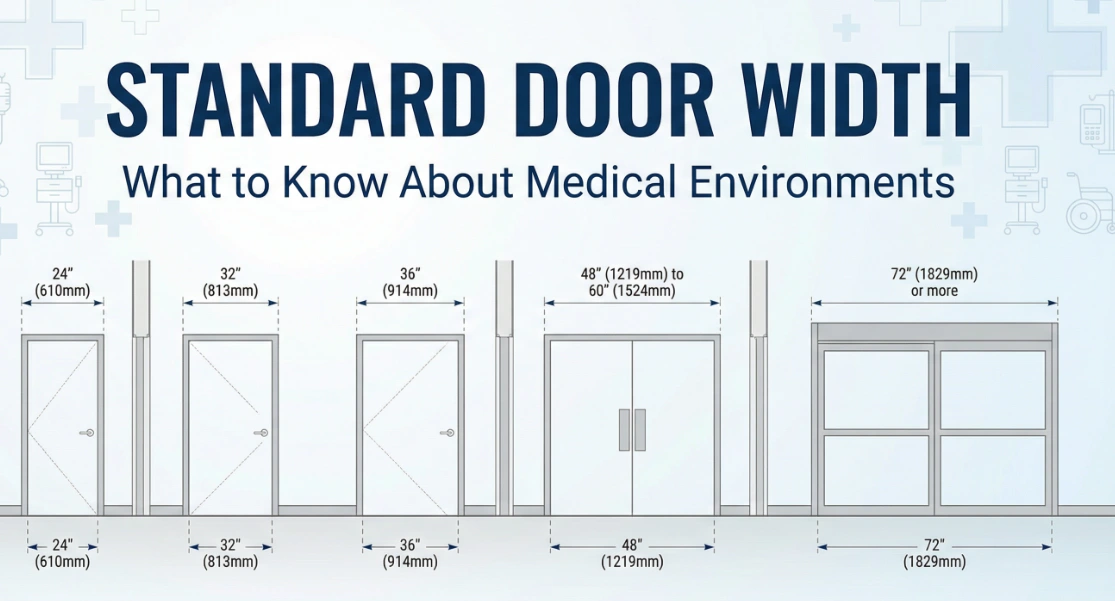

What to Know About Standard Door Width in Medical Environments

What to Know About Standard Door Width in Medical Environments -

What Is a Return Air Vent and Why Does It Matter in HVAC

What Is a Return Air Vent and Why Does It Matter in HVAC -

Top Materials for Durable Pharma Clean Room Doors

Top Materials for Durable Pharma Clean Room Doors -

Hospital Cleanroom Door Design Requirements

Hospital Cleanroom Door Design Requirements -

Swing Doors vs Standard Doors: Which Is Right for Your Facility

Swing Doors vs Standard Doors: Which Is Right for Your Facility -

Cleanroom Door Materials Explained: Key Types and Applications

Cleanroom Door Materials Explained: Key Types and Applications -

How Do Different Vent Grills Impact Medical Cleanrooms

How Do Different Vent Grills Impact Medical Cleanrooms -

Controlled Environment vs Air Clean Room Differences Explained

Controlled Environment vs Air Clean Room Differences Explained -

How to Extend the Life of Your Exterior Steel Door

How to Extend the Life of Your Exterior Steel Door -

What Are the Best Materials for AC Vent Covers

What Are the Best Materials for AC Vent Covers

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.

Speak Your Mind