Exploring E-ZONG: China Clean Room Aluminum Factory Pioneering

- By:hqt

- 2024-05-17

- 29

Unveil E-ZONG, a forefront China Clean Room Aluminum Factory, dedicated to precision and sustainability in manufacturing. Delve into state-of-the-art technologies ensuring unparalleled product quality and efficiency. Explore eco-conscious practices minimizing environmental footprint while meeting stringent regulatory standards. Gain insights into market trends propelling China's leadership in the clean room aluminum sector. Encounter excellence through E-ZONG's rigorous quality control measures, ensuring steadfast consistency and superior products.

Introduction to Clean Room Aluminum Production

1.1 Definition and Significance

Clean room aluminum production refers to the manufacturing process of aluminum products in controlled environments with minimal pollutants and contaminants. This meticulous production method is crucial for industries requiring high-quality aluminum components, such as electronics, aerospace, and medical equipment. Clean room facilities ensure that the final products meet stringent standards for purity, precision, and performance.

1.2 Prevalence in China

China has emerged as a global leader in clean room aluminum production, with numerous state-of-the-art factories dotting its industrial landscape. Among these, E-ZONG stands out as a Pioneering China Clean Room Aluminum Factory, setting new benchmarks in technology, quality, and sustainability.

Technological Innovations in E-ZONG's Clean Room Aluminum Factory

2.1 Advanced Manufacturing Technologies

E-ZONG employs cutting-edge technologies to streamline its clean room aluminum production. These include precision machining, automated handling systems, and robotic assembly lines. By integrating these technologies, E-ZONG ensures high efficiency and accuracy throughout the manufacturing process.

2.2 Innovative Clean Room Processes

At E-ZONG, innovative clean room processes enhance product quality and consistency. This includes the use of advanced filtration systems to maintain air purity, automated cleaning protocols for equipment and workspaces, and stringent contamination control measures. These processes minimize defects and optimize yield, ensuring that every aluminum product meets exacting standards.

2.3 Contribution to Product Quality and Efficiency

The adoption of advanced technologies and processes at E-ZONG significantly contributes to product quality and efficiency. By reducing human error and variability, these innovations enhance precision and reliability in manufacturing. Moreover, streamlined workflows and optimized production cycles improve overall efficiency, enabling E-ZONG to meet the growing demand for high-quality clean room aluminum products.

Environmental Sustainability Practices at E-ZONG

3.1 Eco-Friendly Initiatives

E-ZONG is committed to environmental sustainability, implementing various initiatives to reduce its carbon footprint and minimize environmental impact. This includes investing in energy-efficient equipment, optimizing production processes to reduce waste generation, and sourcing renewable energy sources wherever possible.

3.2 Energy Consumption Reduction

One of E-ZONG's primary sustainability goals is to reduce energy consumption. To achieve this, the factory has implemented energy-saving measures such as LED lighting, motion sensors to control power usage, and heat recovery systems. These initiatives not only lower operating costs but also contribute to a greener, more sustainable manufacturing process.

3.3 Waste Reduction and Recycling

E-ZONG prioritizes waste reduction and recycling as part of its environmental sustainability efforts. Through initiatives such as material recycling programs, waste segregation, and composting, the factory minimizes landfill waste and maximizes resource efficiency. Additionally, E-ZONG collaborates with suppliers to source eco-friendly materials and packaging, further reducing its environmental footprint.

Quality Control and Assurance Measures at E-ZONG

4.1 Stringent Quality Control Measures

E-ZONG prioritizes quality control throughout its clean room aluminum production process. Stringent measures are in place to monitor and regulate every stage of manufacturing, from raw material procurement to final product inspection. This includes comprehensive material testing, dimensional accuracy checks, and surface finish evaluations to ensure that all products meet exacting standards.

4.2 Ensuring Product Quality and Consistency

The implementation of robust quality control measures at E-ZONG ensures product quality and consistency. By conducting rigorous inspections and quality checks at each production step, deviations or defects are promptly identified and rectified. This results in consistently high-quality clean room aluminum products that meet or exceed customer expectations.

4.3 Examples of Quality Assurance Protocols

E-ZONG employs various quality assurance protocols to uphold its commitment to excellence. These include statistical process control (SPC) techniques to monitor production variability, real-time monitoring systems to detect anomalies, and continuous improvement initiatives to address any identified quality issues. Additionally, E-ZONG conducts regular audits and assessments to ensure compliance with internal quality standards and industry regulations.

Market Trends and Growth Potential in the Clean Room Aluminum Industry

5.1 Current Market Trends

The clean room aluminum industry is experiencing significant growth, driven by increasing demand from sectors such as electronics, automotive, and aerospace. Market trends indicate a rising preference for lightweight, durable, and corrosion-resistant aluminum components, fueling the expansion of clean room aluminum production facilities like E-ZONG. Moreover, advancements in technology and manufacturing processes are enhancing product performance and expanding application possibilities.

5.2 Factors Driving Growth in China

China's clean room aluminum industry is poised for substantial growth due to several key factors. The country's robust manufacturing infrastructure, skilled workforce, and strategic investments in research and development contribute to its competitive advantage in this sector. Additionally, the growing emphasis on environmental sustainability and regulatory compliance further incentivizes China Clean Room Aluminum Factory like E-ZONG to adopt cleaner production practices and expand their market presence.

5.3 Future Opportunities and Challenges

Despite the promising growth prospects, the clean room aluminum industry also faces challenges and uncertainties. Fluctuations in raw material prices, geopolitical tensions, and evolving consumer preferences are among the factors that could impact market dynamics. However, with innovation and adaptability, China Clean Room Aluminum Factory like E-ZONG can capitalize on emerging opportunities such as the transition to electric vehicles, urbanization, and infrastructure development.

Regulatory Compliance and Standards in E-ZONG's Operations

6.1 Regulatory Frameworks in China

E-ZONG operates in compliance with stringent regulatory frameworks governing clean room aluminum production in China. These regulations encompass various aspects, including environmental protection, workplace safety, product quality, and export standards. By adhering to these regulations, E-ZONG ensures the integrity of its operations and products while upholding its commitment to responsible manufacturing practices.

6.2 Adherence to International Standards

In addition to domestic regulations, E-ZONG also adheres to international quality standards and certifications to enhance its market competitiveness. These standards, such as ISO 9001 for quality management and ISO 14001 for environmental management, demonstrate E-ZONG's commitment to meeting global benchmarks for excellence and sustainability. Adherence to international standards not only enhances customer confidence but also facilitates access to international markets.

6.3 Importance of Regulatory Compliance

Regulatory compliance is paramount for E-ZONG's market competitiveness and long-term sustainability. By adhering to regulatory requirements and international standards, E-ZONG mitigates risks associated with legal liabilities, reputational damage, and market access barriers. Moreover, regulatory compliance fosters trust and credibility among customers, suppliers, and stakeholders, reinforcing E-ZONG's position as a reliable and responsible industry leader.

Conclusion: E-ZONG's Role in Shaping the Future of Clean Room Aluminum Production

E-ZONG exemplifies leadling China Clean Room Aluminum Factory, combining technological innovation with environmental sustainability. As the demand for high-quality aluminum products continues to grow across industries, E-ZONG's commitment to excellence and eco-friendliness sets a benchmark for the global manufacturing sector. By prioritizing quality, efficiency, and sustainability, E-ZONG is not only shaping the future of clean room aluminum production but also contributing to a cleaner, greener planet.

-

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment

-

Top Aluminium Profile Manufacturers in China: Leading the Global Market

-

The Evolution of Air Tight Sliding Doors

-

AHU Aluminium Profile: A Comprehensive Guide

-

The Importance of Choosing the Right Cleanroom Door in Vietnam

-

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety

-

The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities!

-

Unlock the Possibilities with AJ Manufacturing Doors

-

Make a Statement with Manufactured Home Interior Doors!

-

what is aluminum profile? Aluminum Profiles for Your Home is the best option

-

High Speed Clean Room Doors Cut Contamination Risk

-

Dustproof Cleanroom Door Innovation for Sterile Spaces

-

How Cleanroom Half Glass Swing Door Enhances Sterile Access

-

Why Custom Cleanroom Aluminum Profile Matters Today

-

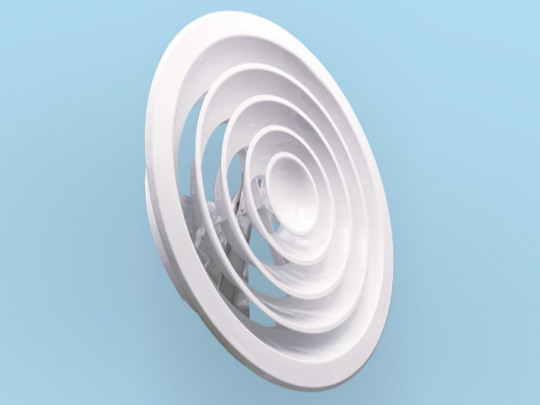

Smart Ceiling Air Diffuser: Dampers Add Full Control

-

E-ZONG: Trusted Air Tight Sliding Cleanroom Door Manufacturer

-

Top Benefits of Clean Room Roll Up Door Systems

-

Cleanroom Glass Door Innovations You Should Know

-

Improve Airflow With the Right Air Diffuser Vent

-

Why Every Laboratory Needs a Sealed Cleanroom Door

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.

.jpg)

Speak Your Mind