Aluminum Profile Cleanroom Doors: Combining Strength and Cleanliness

- By:hqt

- 2024-01-18

- 29

Aluminum Profile Cleanroom Doors, often referred to as cleanroom doors, are specialized entrance solutions designed for controlled environments, such as pharmaceutical facilities, research labs, and semiconductor manufacturing plants. These doors are constructed using aluminum profiles to ensure durability and a clean, sterile environment. The importance of strength and cleanliness in cleanroom doors cannot be overstated. Cleanrooms demand a meticulously controlled environment with minimal contamination risk. The aluminum profile provides the required structural integrity, ensuring the door can withstand the frequent use associated with cleanroom operations while also resisting corrosion in hygienic settings. Furthermore, cleanroom doors are engineered to maintain stringent cleanliness standards, preventing the entry of airborne particles and pathogens. This critical attribute safeguards the sensitive processes and research conducted within cleanrooms, ultimately guaranteeing product quality and worker safety.

The Significance of Cleanroom Doors

Overview of Cleanrooms

Cleanrooms are controlled environments crucial to industries like pharmaceuticals, electronics, and biotechnology. They maintain extremely low levels of airborne particles, contaminants, and microorganisms to ensure the integrity of sensitive processes, research, and production. Contamination within these environments can result in product defects, compromised research, and even health hazards.

Role of Cleanroom Doors in Maintaining Cleanliness

Cleanroom doors play a pivotal role in preserving the pristine conditions of these environments. They serve as barriers that prevent the infiltration of contaminants from adjoining areas. Cleanroom doors are meticulously designed to create airtight seals and feature airlocks to minimize particle transfer during entry and exit. Additionally, they are constructed using materials like aluminum profiles to facilitate easy cleaning, minimizing the risk of particle shedding.

Challenges in Designing Cleanroom Doors

Designing cleanroom doors presents several challenges. These doors must not only meet stringent cleanliness standards but also be structurally robust, reliable, and easy to operate. Achieving a balance between cleanliness and strength can be complex, as any compromise could compromise the integrity of the cleanroom. Moreover, cleanroom doors must adhere to industry-specific regulations and standards, making their design and construction a highly specialized endeavor.

E-ZONG Cleanroom Doors Aluminum Profile

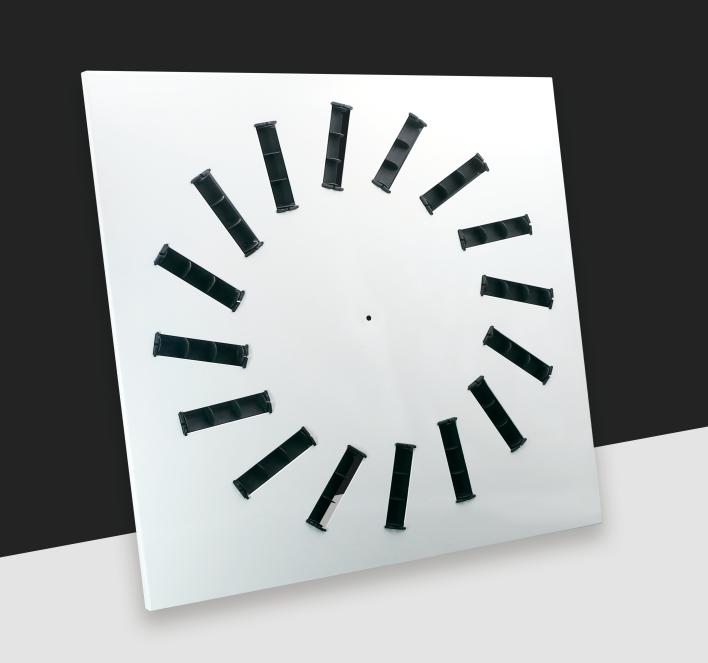

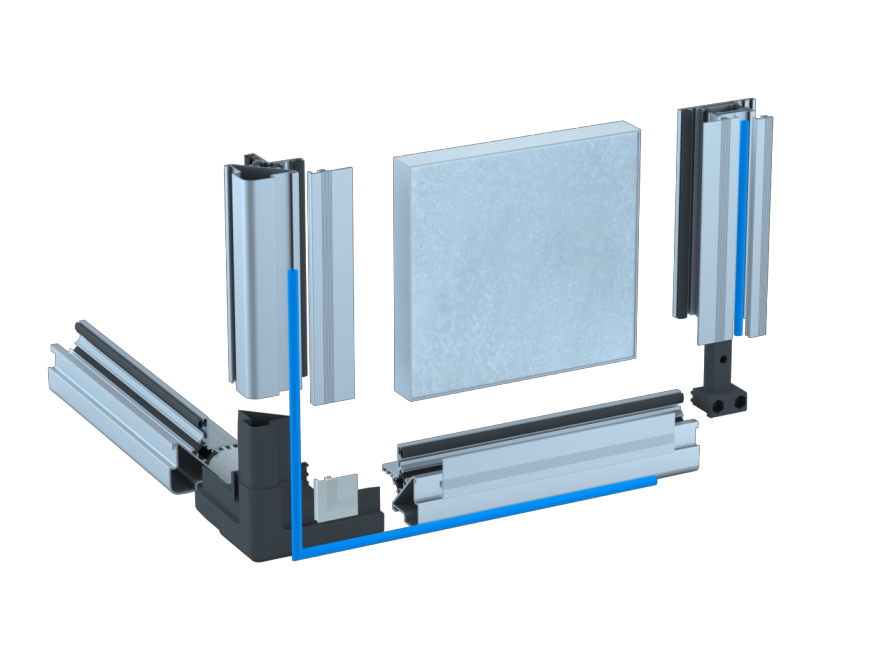

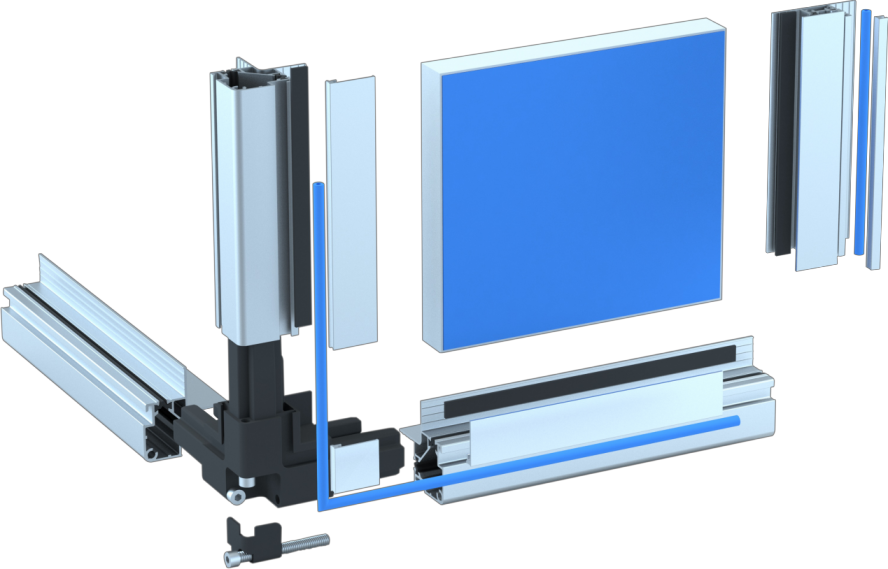

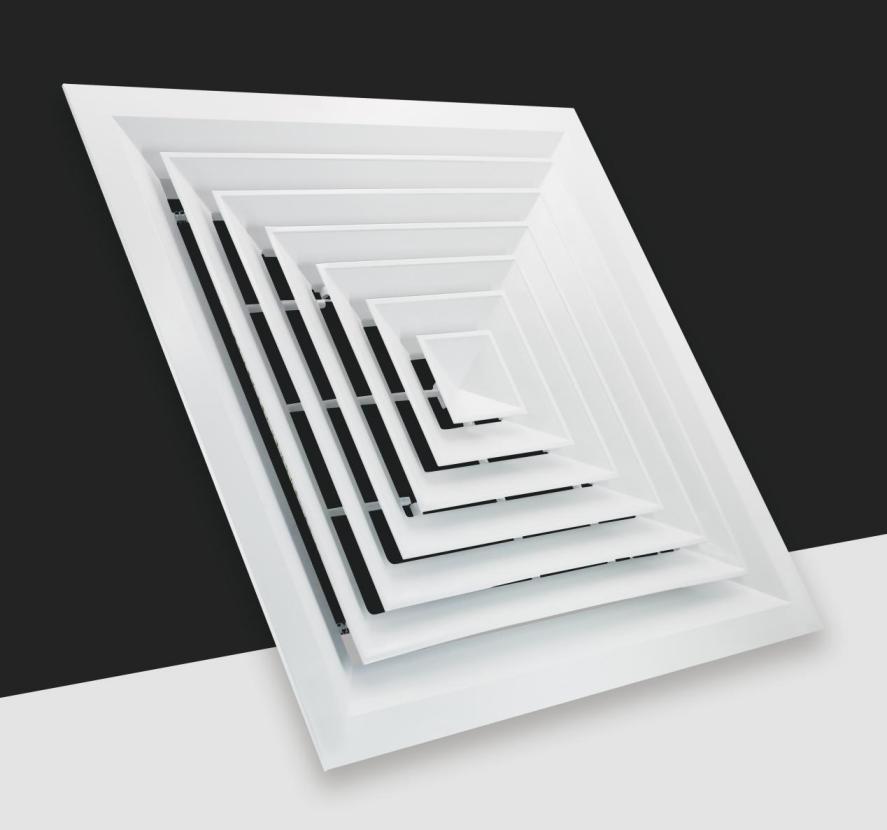

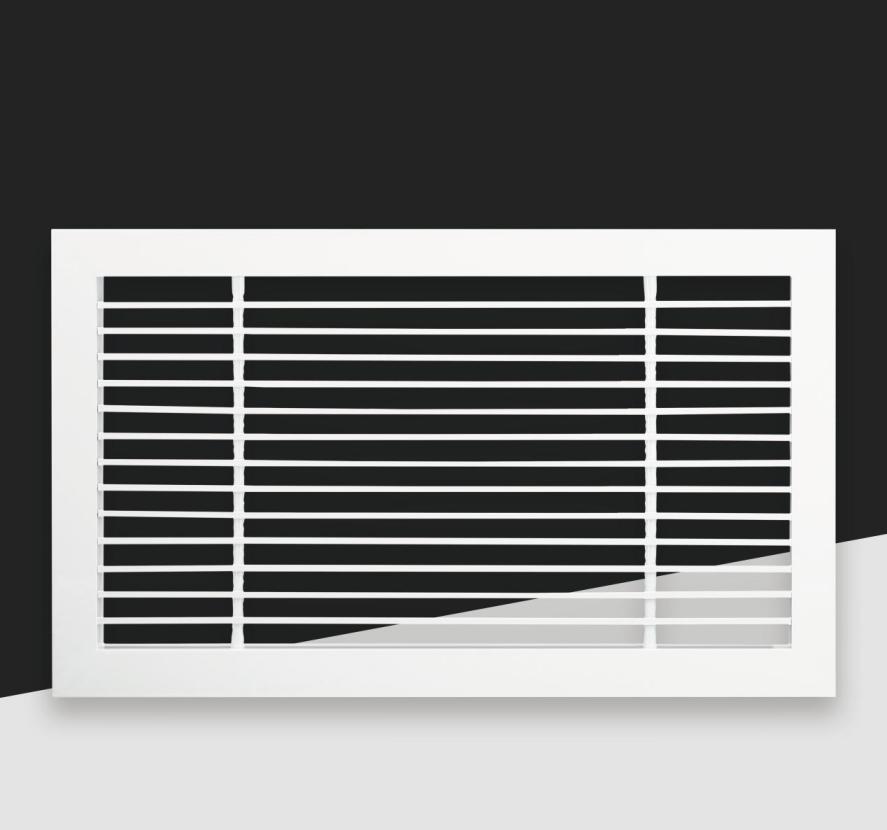

Purification Products Cleanroom Aluminum Series

Characteristics of Aluminum as a Material:

Cleanroom aluminum profiles are essential components that complement modular cleanroom sandwich wall panels in cleanroom projects. These profiles boast distinctive characteristics, making them indispensable in ensuring the success of cleanroom endeavors. Their specialized accessory system exhibits stability, exquisite craftsmanship, and exceptional product quality. They seamlessly integrate with cleanroom sandwich panels, doors, and windows, providing a comprehensive and unified solution for your cleanroom needs.

Advantages of Aluminum Profile Cleanroom Doors:

Cleanroom aluminum profiles offer a multitude of advantages that render them highly suitable for cleanroom environments. Their lightweight nature belies their exceptional strength and durability, enabling them to withstand the demanding and rigorous conditions within cleanroom facilities. Furthermore, these profiles are inherently resistant to corrosion and effortless to clean, ensuring that they maintain their structural integrity and sterility even with extended use.

Common Applications of Aluminum Profile Cleanroom Doors:

Cleanroom aluminum profiles come in various shapes and sizes, making them incredibly versatile and adaptable to diverse construction requirements. They can be designed with features like T-slots, facilitating modular configurations that seamlessly integrate with other cleanroom equipment and systems. Additionally, these profiles can be powder-coated or anodized, offering enhanced protection against wear and tear while improving their overall aesthetic appeal.

Combining Strength and Cleanliness

Design Considerations for Strength

Structural Integrity:

When designing aluminum profile cleanroom doors, one of the primary considerations is ensuring structural integrity. These doors must withstand frequent use in cleanroom environments while maintaining their shape and stability. Aluminum profiles provide the necessary strength, as they are robust and capable of enduring mechanical stress.

Durability:

Cleanroom doors are subjected to rigorous conditions, including temperature variations and potential exposure to chemicals or cleaning agents. Therefore, durability is paramount. Aluminum's inherent resistance to corrosion and rust makes it an ideal choice for cleanroom doors. It ensures the doors can withstand the harsh environment, delivering long-lasting performance.

Design Considerations for Cleanliness

Air-tight Seals:

To maintain the required cleanliness levels within cleanrooms, it is imperative that cleanroom doors create air-tight seals. Any gaps or leaks could allow contaminants to infiltrate the controlled environment. Aluminum profile cleanroom doors are designed with precision to create these tight seals, preventing the ingress of particles and microbes.

Smooth Surface Finishes:

Cleanroom doors must have smooth surface finishes to minimize the risk of particle shedding. Aluminum profiles can be manufactured with precision, resulting in sleek and contamination-resistant surfaces. This design consideration helps uphold the cleanliness standards of the cleanroom.

Balancing Strength and Cleanliness in Aluminum Profile Cleanroom Doors

Balancing strength and cleanliness is a critical aspect of designing aluminum profile cleanroom doors. The inherent strength of aluminum profiles ensures the doors can withstand physical stress and maintain their structural integrity. Simultaneously, their smooth, contaminant-resistant surfaces and air-tight seals contribute to maintaining the required cleanliness levels within the cleanroom.

Achieving this balance is essential because a compromise in either strength or cleanliness could jeopardize the effectiveness of the cleanroom. Aluminum profile cleanroom doors exemplify the successful fusion of these two vital aspects, providing a reliable and durable solution for controlled environments where cleanliness and structural robustness are non-negotiable.

Manufacturing and Construction

Materials and Components

The manufacturing of aluminum profile cleanroom doors begins with carefully selected materials. High-quality aluminum profiles are used for their strength and corrosion resistance. Precision engineering ensures the profiles are cut, shaped, and joined with meticulous attention to detail. Gaskets and seals, often made from materials like silicone or EPDM, are integrated to create air-tight seals. These components are designed to withstand the demanding cleanroom environment.

Assembly and Installation

The assembly of cleanroom doors involves the integration of various components, including aluminum profiles, gaskets, and hardware such as handles and locks. Precision is crucial to ensure a seamless fit and optimal functionality. During installation, the doors are positioned within the cleanroom wall openings, and meticulous care is taken to maintain cleanliness. Proper sealing and alignment are critical to prevent air leakage and contamination.

Quality Control Measures

Quality control is a pivotal aspect of manufacturing aluminum profile cleanroom doors. Rigorous inspections and testing procedures are employed to verify structural integrity, air-tightness, and overall performance. These doors are subjected to stringent quality standards to ensure they meet the cleanliness and durability requirements of cleanroom environments.

Maintenance and Cleaning

Routine Maintenance Practices

To ensure the longevity and performance of aluminum profile cleanroom doors, routine maintenance is essential. This includes inspecting seals and gaskets for wear or damage, lubricating hinges and moving parts, and checking for any signs of wear and tear. Regular maintenance prevents unexpected issues and ensures that the doors continue to function effectively.

Cleaning Procedures for Aluminum Profile Cleanroom Doors

Cleanroom doors themselves require cleaning to maintain cleanliness standards. Cleaning procedures involve using non-abrasive, compatible cleaning agents to wipe down the aluminum surfaces, gaskets, and other components. Care is taken to prevent particle shedding during the cleaning process, and doors are often cleaned in conjunction with the surrounding cleanroom area.

Ensuring Longevity and Efficiency

Proper maintenance and cleaning not only extend the lifespan of aluminum profile cleanroom doors but also ensure their continued efficiency in maintaining cleanliness. Regular inspections can detect any potential issues early, allowing for timely repairs or replacements. By investing in maintenance and cleaning, cleanroom operators can optimize the performance and reliability of their doors.

Future Trends and Innovations

Advancements in Aluminum Profile Cleanroom Door Technology

As technology evolves, so does the design and functionality of cleanroom doors. Advancements may include enhanced sealing mechanisms, improved insulation properties, and innovations in door opening mechanisms for touchless operation, promoting greater cleanliness and convenience.

Sustainability and Eco-friendly Options

In response to environmental concerns, future trends may see the development of eco-friendly and sustainable materials for cleanroom doors. Additionally, energy-efficient designs and materials that minimize heat transfer and reduce energy consumption could become more prevalent.

Integration of Smart Technologies

The integration of smart technologies into cleanroom doors is on the horizon. This may involve IoT-based monitoring systems for real-time status updates, access control solutions with biometrics or RFID, and automation features to optimize door operation in response to cleanliness requirements.

In Closing

In conclusion, E-ZONG Aluminum Profile Cleanroom Doors exemplify the perfect synergy of strength and cleanliness in the realm of controlled environments. With meticulously designed aluminum profiles, these doors offer exceptional structural integrity and durability, capable of withstanding the rigors of cleanroom operations. Their inherent resistance to corrosion and ease of cleaning ensures that they maintain their pristine condition, upholding stringent cleanliness standards. The careful consideration of design factors, such as air-tight seals and smooth surface finishes, ensures that these doors effectively safeguard the cleanliness and sterility of cleanroom environments. Moreover, their adaptability, ease of maintenance, and integration of future innovations position E-ZONG Aluminum Profile Cleanroom Doors as a pivotal component in maintaining the integrity and efficiency of cleanroom facilities, both now and in the dynamic landscape of tomorrow's controlled environments.

-

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment -

Top Aluminium Profile Manufacturers in China: Leading the Global Market

Top Aluminium Profile Manufacturers in China: Leading the Global Market -

The Evolution of Air Tight Sliding Doors

The Evolution of Air Tight Sliding Doors -

AHU Aluminium Profile: A Comprehensive Guide

AHU Aluminium Profile: A Comprehensive Guide -

The Importance of Choosing the Right Cleanroom Door in Vietnam

The Importance of Choosing the Right Cleanroom Door in Vietnam -

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety -

.jpg) The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities!

The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities! -

Unlock the Possibilities with AJ Manufacturing Doors

Unlock the Possibilities with AJ Manufacturing Doors -

Make a Statement with Manufactured Home Interior Doors!

Make a Statement with Manufactured Home Interior Doors! -

what is aluminum profile? Aluminum Profiles for Your Home is the best option

what is aluminum profile? Aluminum Profiles for Your Home is the best option

-

Guide to Doors Clean Room: Ensuring Contamination Control

Guide to Doors Clean Room: Ensuring Contamination Control -

Introducing Guangdong Clean Room Aluminum Company: E-ZONG

Introducing Guangdong Clean Room Aluminum Company: E-ZONG -

Cost-Effectiveness of Bulk Purchasing Air Diffuser

Cost-Effectiveness of Bulk Purchasing Air Diffuser -

Makeup Air Handling Unit: Here to Know

Makeup Air Handling Unit: Here to Know -

Customizing HVAC Systems Parts for Building Specific Needs

Customizing HVAC Systems Parts for Building Specific Needs -

How Return Air Diffuser Enhances HVAC Efficiency for Your Projects

How Return Air Diffuser Enhances HVAC Efficiency for Your Projects -

Exploring the Versatility of Swing Glass Door

Exploring the Versatility of Swing Glass Door -

Choosing Quality: Why Linear Diffuser Grille is Essential in Modern Design

Choosing Quality: Why Linear Diffuser Grille is Essential in Modern Design -

Introduction to Clean Room High Speed Doors: Let’s Dive into

Introduction to Clean Room High Speed Doors: Let’s Dive into -

High-Quality Clean Room Double Door for Medical and Health

High-Quality Clean Room Double Door for Medical and Health

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.

Speak Your Mind