The Benefits of Aluminum Clean Room Wall Panels

- By:ren

- 2022-11-03

- 29

Have you ever worked in a clean room? These spaces are designed to be as free of dust, dirt, and other contaminants as is humanly possible. In other words, they need to have as little particulate matter floating around in the air as is possible. Because of this need for cleanliness, many manufacturers will outsource the construction of their clean rooms to third parties who specialize in creating these unique spaces. Clean rooms are often referred to by different names depending on what kind of work is being done there, but the concept remains the same: Keep contaminants out and have nothing inside that could contaminate whatever it is that you’re working on. The purpose of this blog post is to introduce you to some of the different types of aluminum clean room wall panels that can be used in this type of environment.

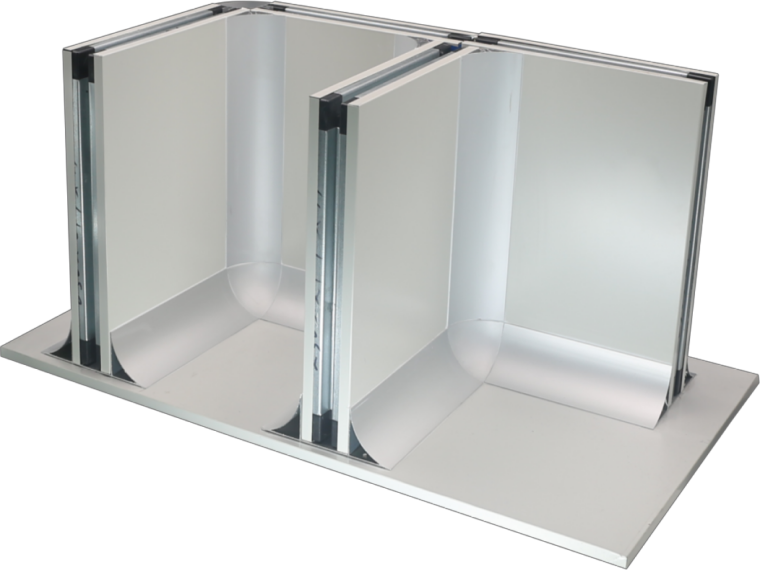

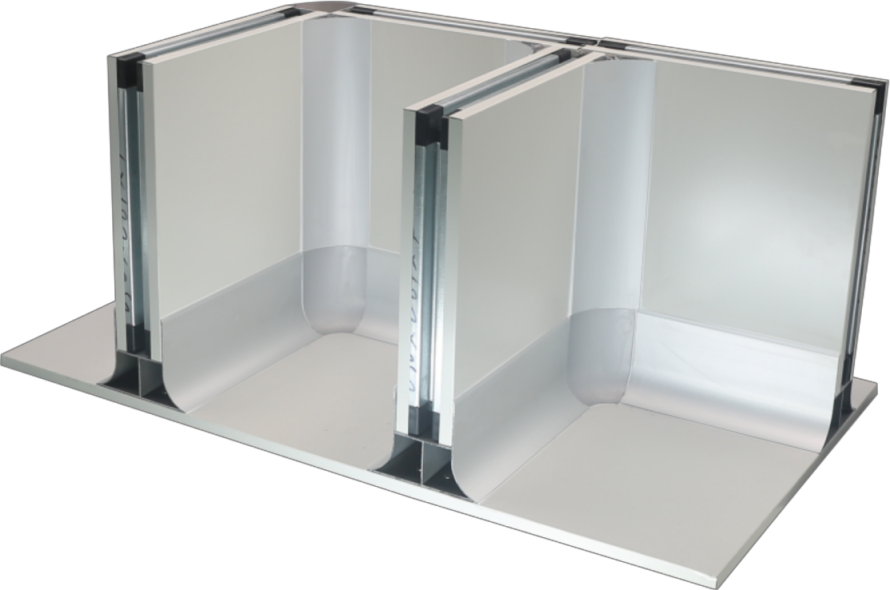

What are aluminum clean room wall panels?

As their name implies, clean room wall panels are the materials used to construct the walls of clean rooms. The main function of clean room wall panels is to keep contaminants out of the air inside the clean room. Clean room walls are sealed to prevent dust and other dirt particles from getting inside, but they also have air filters to keep contaminated air from getting out. Aluminum is often used because it can be easily sealed and is resistant to corrosion. In addition to preventing contaminants from getting out of a clean room, aluminum clean room wall panels can also be used to help prevent contaminants from getting in. Some clean room wall panels have a porous surface that allows air to pass through them but does not let particles pass. Other walls have a smooth surface that is difficult for dirt and other contaminants to stick to.

How do aluminum clean room wall panels benefit cleanrooms?

As mentioned above, clean rooms have to be as free of contaminants as possible. Even the smallest amount of dirt or dust can contaminate whatever product is being manufactured inside the clean room. Aluminum clean room wall panels help prevent this from happening by keeping contaminants out of the air and off of the products being made. Clean room wall panels also help to keep people inside the clean rooms healthier. When the air inside a clean room is dirtier than the air outside, employees are more likely to get sick. Clean room wall panels help to keep the air inside a clean room cleaner than the air outside so that employees can stay healthy. Clean rooms also have to be designed with a special layout, as they require a lot of space. They usually need to be twice as long as they are wide, with a ceiling at least 10 feet high. Clean room wall panels can be designed and manufactured in a variety of different sizes and shapes to help them fit into the various layouts required by clean rooms.

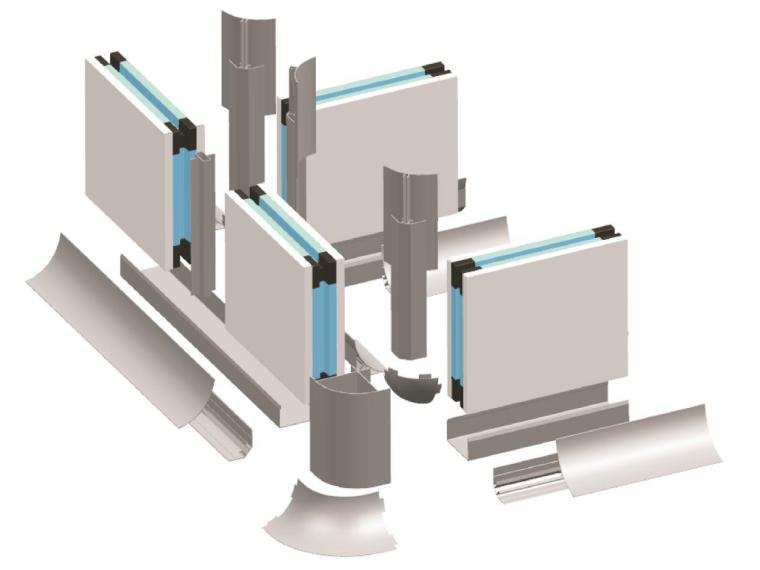

The Different Types of Aluminum Clean Room Wall Panels

There are many different types of aluminum clean room wall panel designs. Below are the most common designs used when constructing clean room walls. - Standard Smooth Panel - This is the most basic clean room wall panel. It is a single sheet of aluminum that is sandwiched between two sheets of cardboard. This design is very easy to install and does not require any specialized tools. However, it does have some disadvantages. Standard smooth panels are more porous than other designs and are more difficult to seal. They are also the least durable type of clean room wall panel. - Aluminium Treadmill Panel - Treadmill panels are slightly more durable than standard smooth panels. They are made of two aluminum sheets and two sheets of plastic sandwiched together between two sheets of cardboard. One of the aluminum sheets and one of the cardboard sheets are attached to one another, and the other two layers are attached to the other aluminum sheet. This creates a seal along the entire edge of the clean room wall. - Aluminum Labyrinth Panel - Labyrinth panels are the most durable type of clean room wall panel. They are made of two aluminum sheets and two sheets of plastic sandwiched tightly between two sheets of cardboard. The two aluminum sheets and two cardboard sheets are attached to one another, and the other two sheets are attached to the other aluminum sheet. This creates a seal along the entire edge of the clean room wall. - Aluminium DuPont Panel - DuPont panels are similar to labyrinth panels in that they are very durable. They are made of three aluminum sheets and three sheets of plastic sandwiched tightly between three sheets of cardboard. The three aluminum sheets and three cardboard sheets are attached to one another and the other three sheets are attached to the other aluminum sheet. This creates a seal along the entire edge of the clean room wall. - Aluminium Electronic Grade Panels - Electronic grade panels are the sturdiest and most durable clean room wall panels. They are made of four aluminum sheets and four sheets of plastic sandwiched between four sheets of cardboard. The four aluminum sheets and four cardboard sheets are attached to one another and the other four sheets are attached to the other aluminum sheet. This creates a seal along the entire edge of the clean room wall.

What Is an Aluminum Clean Room Wall?

Because clean rooms are designed to be as free of contaminants as is possible, they need to be completely sealed off from the rest of the building. The walls of clean rooms are often constructed out of aluminum clean room wall panels. These walls help to keep contaminants out and make sure that nothing inside the clean room can contaminate anything outside of it. When you look at photos of clean rooms, you are probably thinking that all of the walls inside of them are made of the same material. This is not the case. The walls that are used inside of clean rooms have been designed to be completely airtight. They have been fitted with special seals and gaskets to ensure that no air, dust, or other contaminants get inside.

Type I - Standard Smooth Panel

There are many different types of clean room wall panels, but the most basic one is the standard smooth panel. Standard smooth panels are a single sheet of aluminum sandwiched between two sheets of cardboard. These panels are very easy to install and do not require any special tools. However, they are also the least durable type of clean room wall panel and the least resistant to corrosion. Standard smooth panels are not ideal for use in clean rooms that have corrosive chemicals or strong cleaning agents being used inside of them because they can be easily damaged by these chemicals.

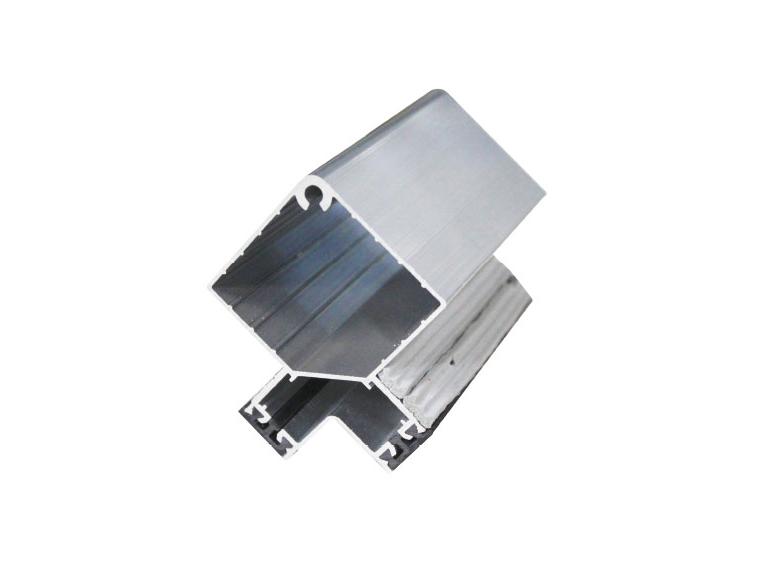

Aluminium Treadmill Panel

Treadmill panels are a little more durable than standard smooth panels. They are made of two aluminum sheets and two sheets of plastic sandwiched between two sheets of cardboard. One of the aluminum sheets and one of the cardboard sheets are attached to one another, and the other two layers are attached to the other aluminum sheet. This creates a seal along the entire edge of the clean room wall. Treadmill panels are a little more resistant to corrosion than standard smooth panels and do not need to be replaced as often. However, they are also more difficult to install and require a specialized sealing tool.

Aluminum Labyrinth Panel

Labyrinth panels are the most durable type of clean room wall panel. They are made of two aluminum sheets and two sheets of plastic sandwiched between two sheets of cardboard. The two aluminum sheets and two cardboard sheets are attached to one another, and the other two sheets are attached to the other aluminum sheet. This creates a seal along the entire edge of the clean room wall. Labyrinth panels are the most resistant to corrosion of the three types of panels listed above and are the best choice for clean rooms that contain chemicals or cleaning agents that can damage other types of panels. However, they are also the most difficult to install and require a specialized sealing tool and specialized tools to cut them down to the proper size.

Aluminium DuPont Panel

DuPont panels are very similar to labyrinth panels in that they are the most durable and corrosion-resistant type of clean room wall panel. DuPont panels are made of three aluminum sheets and three sheets of plastic sandwiched between three sheets of cardboard. The three aluminum sheets and three cardboard sheets are attached to one another and the other three sheets are attached to the other aluminum sheet. This creates a seal along the entire edge of the clean room wall. DuPont panels are the most corrosion-resistant type of clean room wall panels, but they are also the most difficult to install and require a specialized sealing tool.

Aluminium Electronic Grade Panels

Electronic grade panels are the sturdiest and most durable clean room wall panels. They are made of four aluminum sheets and four sheets of plastic sandwiched between four sheets of cardboard. The four aluminum sheets and four cardboard sheets are attached to one another and the other four sheets are attached to the other aluminum sheet. This creates a seal along the entire edge of the

-

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment -

Top Aluminium Profile Manufacturers in China: Leading the Global Market

Top Aluminium Profile Manufacturers in China: Leading the Global Market -

The Evolution of Air Tight Sliding Doors

The Evolution of Air Tight Sliding Doors -

AHU Aluminium Profile: A Comprehensive Guide

AHU Aluminium Profile: A Comprehensive Guide -

The Importance of Choosing the Right Cleanroom Door in Vietnam

The Importance of Choosing the Right Cleanroom Door in Vietnam -

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety -

.jpg) The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities!

The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities! -

Unlock the Possibilities with AJ Manufacturing Doors

Unlock the Possibilities with AJ Manufacturing Doors -

Make a Statement with Manufactured Home Interior Doors!

Make a Statement with Manufactured Home Interior Doors! -

what is aluminum profile? Aluminum Profiles for Your Home is the best option

what is aluminum profile? Aluminum Profiles for Your Home is the best option

-

Designing a Flexible Clean Room Aluminum Profile System

Designing a Flexible Clean Room Aluminum Profile System -

Look for in Cleanroom Aluminum Profile Wholesaler. Here to Know

Look for in Cleanroom Aluminum Profile Wholesaler. Here to Know -

HVAC Air Diffusion Products Myths Debunked: What You Really Need to Know

HVAC Air Diffusion Products Myths Debunked: What You Really Need to Know -

Why Opt Aluminum Profiles For Air Handling Units: Custom Service

Why Opt Aluminum Profiles For Air Handling Units: Custom Service -

Understanding Doors & Windows for Cleanrooms Seals Solutions:

Understanding Doors & Windows for Cleanrooms Seals Solutions: -

Options for Doors in a Cleanroom: Which Type is Right for You?

Options for Doors in a Cleanroom: Which Type is Right for You? -

6 Considerations In Choosing Clean Room Doors

6 Considerations In Choosing Clean Room Doors -

Cleanroom Doors Sliding Doors: Which Is Best for Your Facility?

Cleanroom Doors Sliding Doors: Which Is Best for Your Facility? -

Choosing the Right Hygienic Doors for Your Facility

Choosing the Right Hygienic Doors for Your Facility -

Cleanroom Aluminum Profile Wholesale Market: Key Trends and Insights

Cleanroom Aluminum Profile Wholesale Market: Key Trends and Insights

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.

Speak Your Mind