A comprehensive overview: AHU modular framing systems

- By:hqt

- 2023-04-11

- 29

What is meant by AHU modular framing systems?

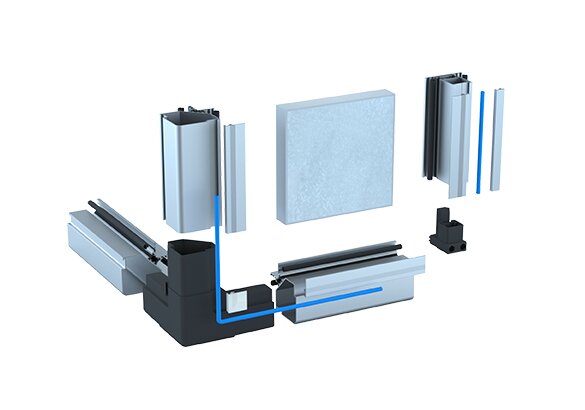

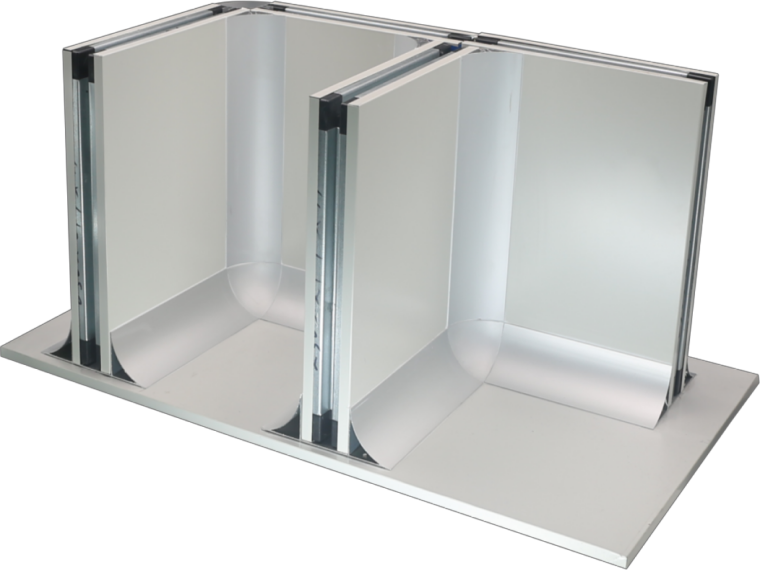

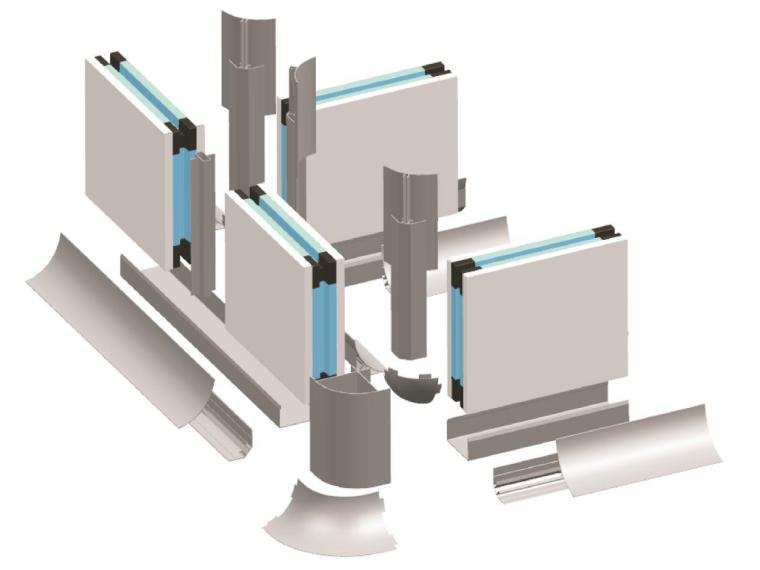

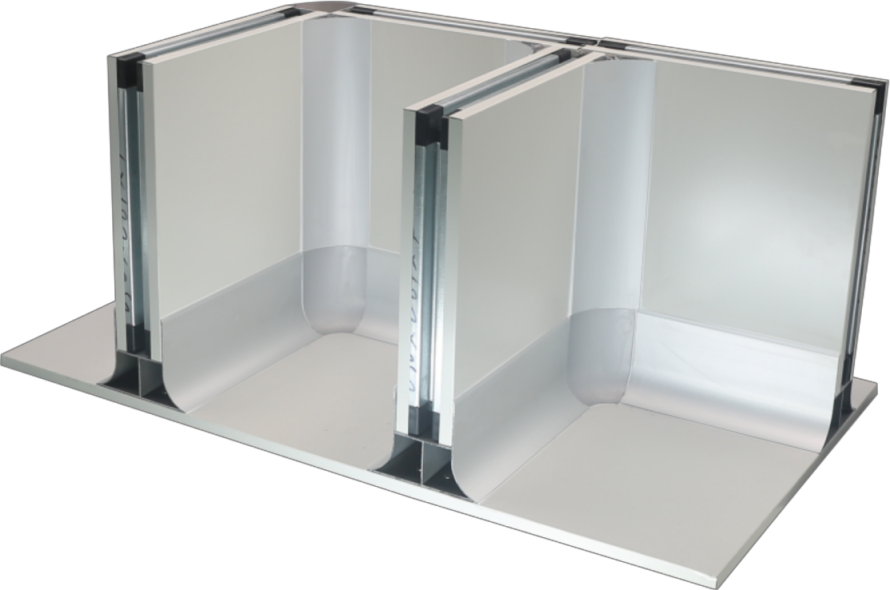

- HVAC (heating, ventilation, and air conditioning) systems employ air handling units, or AHUs, to move and control air. Pre-engineered parts that can be swiftly put together on-site to produce a range of structures are used in a modular frame system, a construction technique. Thus, the term "AHU modular framing systems" refers to the use of pre-engineered modular parts in the building of air handling units. Examples of these modular components are framing supplies, panels, ductwork, and other HVAC parts.

- Numerous advantages of using modular frame systems in AHUs include more flexibility in design and layout, decreased construction time and cost, and increased energy efficiency. Furthermore, the modular structure makes upgrading and replacing individual parts simple, which is useful when some parts need to be maintained or replaced. Generally speaking, using modular frame systems in AHUs may be a useful approach to speed up the building process and provide more effective and adaptable HVAC systems.

AHU remove airborne dust and black smoke:

The most basic centralized system is an all-air, single-zone setup that normally includes fans, heaters, coolers, and filters. The term "AHU" here refers to a return air system. Its fundamental operation is as follows: external fresh air and some inside return airs are combined, and then airborne dust, soot, black smoke, organic particles, and other dangerous elements are removed using a filter. The air in a building or other enclosed area is conditioned and circulated using an air handling unit (AHU). A frame that supports numerous parts, including filters, fans, and heating and cooling coils, is the basic structure of an AHU. The framework that binds these parts together and supports the AHU is called the frame. The size and form of the frame are referred to as the frame profile. AHU frames may be created in a variety of sizes and forms to meet a variety of requirements. They can be made of different materials, such as steel or aluminium.

What are the advantages of modular AHU frame systems?

Due to their various benefits, AHU modular frame systems are becoming more and more common in the market today. By utilizing AHU frame technologies, users may build an AHU to their particular specs and demands while also getting a flexible, extensible system that is simple to modify to meet changing needs. Air handling unit modular frame solutions come with several advantages that may speed up construction and cut costs while enhancing air handling units' performance, efficiency, and sustainability. Using AHU modular frame techniques to build air handling units has several advantages. Following are some of the primary advantages:

- Savings in time and money:

Because many components are pre-engineered and easily installed on-site, modular building may be finished significantly more rapidly than traditional construction techniques. Cutting down on labour and construction time may save a lot of money.

- Flexibility and personalization:

Modular frame systems are easily customizable to satisfy unique design and layout needs. This gives designers of the air handling unit more flexibility and can help guarantee that the finished product will suit the unique requirements of the building and its users.

- Improved quality control:

Greater uniformity and quality control are possible because modular components are frequently produced in a controlled environment off-site. This may lead to an air handling unit of a higher caliber that operates more successfully and effectively.

- Sustainability:

Since it frequently produces less waste and consumes less resources than conventional construction techniques, modular construction might be a more sustainable solution. Additionally, the adaptability and simplicity of replacing individual parts can assist in increasing the air handling unit's lifespan, reducing waste and material usage over time.

- Reduced disruption:

Since much of the construction work may be conducted off-site and then swiftly assembled on-site, modular construction can be less disruptive to building occupants and surrounding properties. This can lessen the commotion caused by building projects, such as dust, noise, and other distractions.

Different applications of Air handling unit modular framing systems:

Several applications call for the employment of air-handling unit modular frame systems. AHU modular frame systems are frequently used for the following purposes:

- Commercial structures:

AHU frame systems are frequently utilized in structures like office buildings, malls, and hospitals that are employed for commercial purposes. These systems may be modified to provide ventilation, heating, and cooling depending on the requirements of the building and its inhabitants.

- Industrial facilities:

AHU frame systems may also be utilized to offer temperature control and ventilation for production areas in industrial facilities, such as factories and manufacturing plants.

- Data centers:

Data centers need to precisely manage the temperature and humidity to guarantee that servers and other electronic equipment are working properly. As technology advances, AHU modular frame systems may offer this degree of control while also being readily changed or replaced.

- Cleanrooms:

In cleanroom settings, such as pharmaceutical production plants and labs, where air quality and cleanliness are crucial, AHU modular frame systems are frequently employed.

- Educational facilities:

AHU modular frame systems can be employed in educational institutions like schools and universities to give students and teachers a cosy and healthy learning environment.

Many AHU frame profiles have the same characteristics:

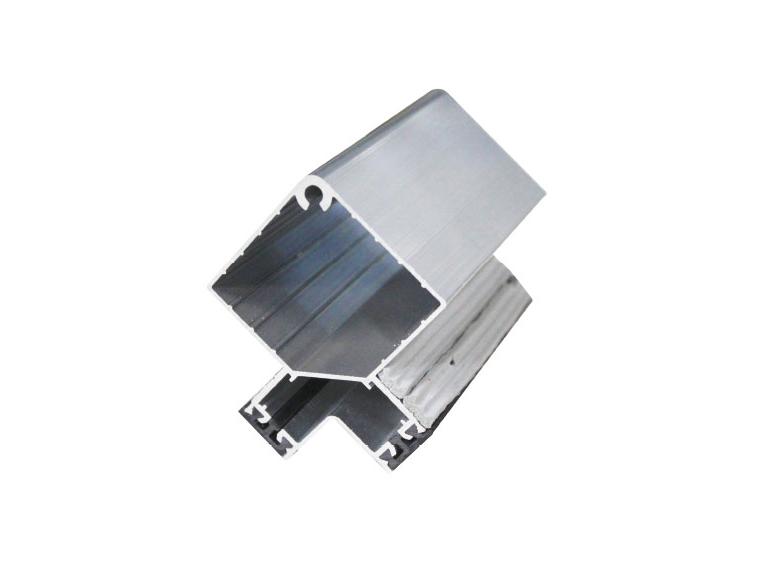

- Materials used: AHU frames can be built of steel, aluminum, or other materials, each with pros and cons.

- Material thickness: The AHU frame's strength and endurance will be influenced by the material thickness utilized in its construction.

- The frame's form might vary depending on the size and kind of unit. AHU frames can also have various profiles.

- The frame's dimensions: AHU frames are available in various dimensions to meet the needs of various HVAC (heating, ventilation, and air conditioning) systems and building types.

- When choosing an AHU for a particular application, it's crucial to keep the frame profile of the unit in mind. When choosing an AHU for a particular application, it's crucial to consider the frame profile. Selecting an AHU with a frame that is sturdy and long-lasting enough to hold up the unit's parts and endure the strains of typical operation is critical.

Conclusion:

AHU modular frame systems are adaptable, effective, and sustainable solutions for regulating indoor air quality and comfort in various applications requiring air handling units. Our products are among the highest quality in the industry and are made with various CNC machining equipment. E-ZONG now employs over 300 people, and its facility spans more than 30,000 square meters. We have more than 26 years of experience in the development sector and have a strong foundation in project management and quality assurance.

-

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment -

Top Aluminium Profile Manufacturers in China: Leading the Global Market

Top Aluminium Profile Manufacturers in China: Leading the Global Market -

The Evolution of Air Tight Sliding Doors

The Evolution of Air Tight Sliding Doors -

AHU Aluminium Profile: A Comprehensive Guide

AHU Aluminium Profile: A Comprehensive Guide -

The Importance of Choosing the Right Cleanroom Door in Vietnam

The Importance of Choosing the Right Cleanroom Door in Vietnam -

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety -

.jpg) The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities!

The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities! -

Unlock the Possibilities with AJ Manufacturing Doors

Unlock the Possibilities with AJ Manufacturing Doors -

Make a Statement with Manufactured Home Interior Doors!

Make a Statement with Manufactured Home Interior Doors! -

what is aluminum profile? Aluminum Profiles for Your Home is the best option

what is aluminum profile? Aluminum Profiles for Your Home is the best option

-

Designing a Flexible Clean Room Aluminum Profile System

Designing a Flexible Clean Room Aluminum Profile System -

Look for in Cleanroom Aluminum Profile Wholesaler. Here to Know

Look for in Cleanroom Aluminum Profile Wholesaler. Here to Know -

HVAC Air Diffusion Products Myths Debunked: What You Really Need to Know

HVAC Air Diffusion Products Myths Debunked: What You Really Need to Know -

Why Opt Aluminum Profiles For Air Handling Units: Custom Service

Why Opt Aluminum Profiles For Air Handling Units: Custom Service -

Understanding Doors & Windows for Cleanrooms Seals Solutions:

Understanding Doors & Windows for Cleanrooms Seals Solutions: -

Options for Doors in a Cleanroom: Which Type is Right for You?

Options for Doors in a Cleanroom: Which Type is Right for You? -

6 Considerations In Choosing Clean Room Doors

6 Considerations In Choosing Clean Room Doors -

Cleanroom Doors Sliding Doors: Which Is Best for Your Facility?

Cleanroom Doors Sliding Doors: Which Is Best for Your Facility? -

Choosing the Right Hygienic Doors for Your Facility

Choosing the Right Hygienic Doors for Your Facility -

Cleanroom Aluminum Profile Wholesale Market: Key Trends and Insights

Cleanroom Aluminum Profile Wholesale Market: Key Trends and Insights

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.

Speak Your Mind