What Are the Best Materials for AC Vent Covers

- By:Lisa

- 2025-11-18

- 29

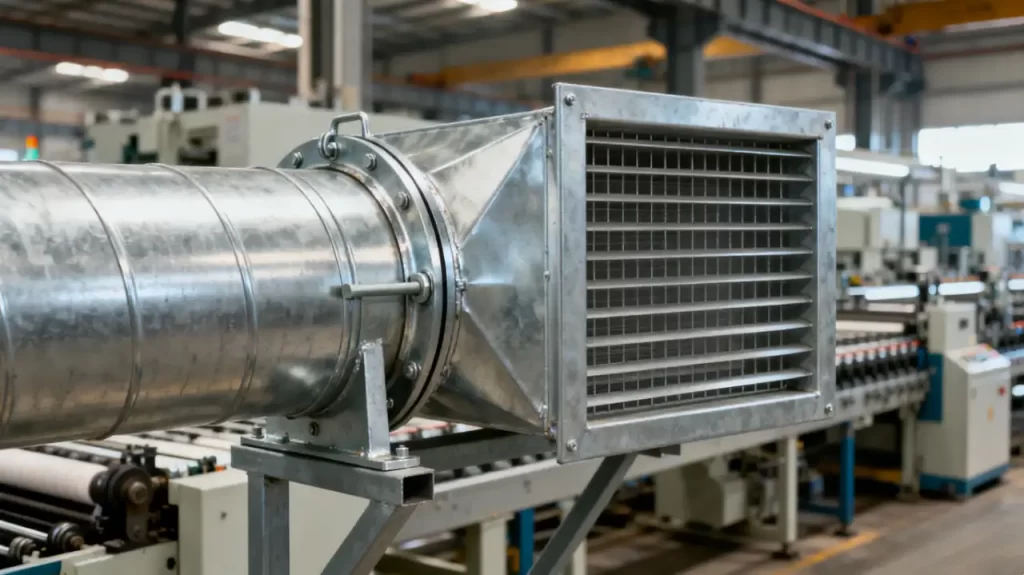

In modern building systems, the performance of an HVAC system doesn’t end at the ductwork — it hinges on the details. Among the most overlooked yet critical components are air diffuser grilles, commonly referred to in residential and light commercial contexts as AC vent covers. These small fixtures don’t just direct airflow — they influence indoor air quality, acoustic comfort, energy efficiency, and long-term system reliability.

Nowhere is this more evident than in high-stakes environments like hospital operating rooms, pharmaceutical cleanrooms, semiconductor fabs, and data centers. In these settings, an AC vent cover that warps, corrodes, or accumulates dust doesn’t just look bad — it compromises containment, increases maintenance burdens, and can even trigger system failures.

Yet, in practice, AC vent covers are often selected based on aesthetics or upfront cost — not durability. According to ASHRAE’s 2022 HVAC Maintenance Cost Analysis Report, while end-use components like vent covers account for less than 3% of initial system investment, they contribute to over 18% of total lifecycle maintenance costs due to premature failure, replacement, and downtime.

Why Material Choice Determines the Long-Term Reliability of AC Vent Covers

Though small and seemingly simple, AC vent covers perform multiple critical functions:

- Airflow control: Directing air via louver angles to achieve laminar, diffused, or swirling patterns

- Backdraft prevention: Blocking contaminated air from entering ducts when the system is off

- Structural support: Holding filters, silencers, or dampers in place

- Aesthetic integration: Blending with ceilings and architectural finishes

- Sealing integrity: In cleanrooms and sterile zones, maintaining airtight connections to prevent leakage

When material selection fails, the consequences cascade:

1.1 Structural Failure: Warping and Collapse

- Engineered plastics (e.g., ABS, PC) undergo creep under sustained heat (>60°C). ASTM D2990 testing shows PC/ABS alloys can deform by 0.8–1.5% over 1,000 hours at 70°C and 5 MPa stress — causing louvers to jam or misalign.

- Galvanized steel corrodes rapidly in humid, sulfur-rich environments. At relative humidity >70%, zinc coating degrades at 8–12 μm/year (ISO 9223 C3). Within 2–3 years, the underlying steel is exposed and begins to rust through.

1.2 Airflow Disruption: Noise and Energy Loss

- Rough edges or poor flatness (>1 mm deviation) increase local resistance coefficients (ζ) by 0.15–0.3, reducing airflow by 3–7%. Fans compensate by increasing speed — consuming 5–10% more energy.

- Real-world measurements show galvanized steel AC vent covers in office spaces generate 42 dB(A) of noise; precision anodized aluminum units operate at just 34 dB(A) — an 8 dB difference perceived as nearly twice as loud.

1.3 Rising Maintenance Costs: Cleaning and Replacement Frequency

- In one hospital case study, plastic AC vent covers required cleaning 3.2 times per year; anodized aluminum required only 1.1. Over three years, maintenance costs for plastic units were 47% higher.

- In a coastal chemical plant, galvanized steel AC vent covers had to be replaced every 18 months. Over a decade, replacement costs exceeded the initial purchase price by 3.6x.

A truly durable AC vent cover must deliver five core attributes:

- Corrosion resistance — withstands moisture, chemicals, salt

- Dimensional stability — no warping, sagging, or creep under thermal load

- Mechanical strength — resists impact and deformation

- Easy-to-clean surface — low particle adhesion, compatible with disinfectants

- Seal compatibility — integrates seamlessly with ceiling systems for airtight performance

Four Primary Materials Compared: Performance Under Real-World Conditions

2.1 Anodized Aluminum: The Gold Standard for Cleanrooms and High-End Applications

6063-T5 or 6061-T6 aluminum alloy is the preferred material for premium commercial and institutional projects. With a density of just 2.7 g/cm³ — one-third that of stainless steel — it reduces ceiling load significantly.

When anodized, the surface forms a hard, ceramic-like layer of aluminum oxide (Al₂O₃), 10–25 μm thick, with a hardness of HV 300–600 — far exceeding the base alloy’s HV 90–120.

2.1.1 Superior Corrosion Resistance

- Survives 1,000+ hours of neutral salt spray (NSS, ISO 9227) with zero red rust — suitable for ISO 9223 C4 environments (moderate industrial, coastal urban).

- Chemically inert across pH 4–9, safe for use near cleaning agents and sterilization systems.

- No metal ion leaching — critical in data centers where corrosion can damage server components.

2.1.2 Thermal Stability

- Coefficient of thermal expansion: 23.6 × 10⁻⁶ /°C. Dimensions remain stable between -40°C and +150°C — ideal for systems with frequent cooling/heating cycles.

- Thermal conductivity: 160–180 W/(m·K) — helps prevent condensation on cold-air diffusers.

2.1.3 Surface Performance

- Post-anodizing surface roughness (Ra) can be controlled to 0.4–0.8 μm — smooth enough to resist dust and microbial buildup.

- Compatible with alcohol, IPA, or hospital-grade disinfectants without degradation.

- UV-resistant for up to 1,000 hours (ISO 4892-2), with minimal fading or chalking.

2.1.4 Compatibility with Modular Systems

- Can be engineered with integrated T-slots, sealing grooves, and mounting holes for seamless integration with cleanroom wall panels and suspended ceiling grids.

- When paired with silicone gaskets, achieves leakage rates <0.1% under 5 Pa differential pressure — meeting ISO 14644-1 Class 5–8 cleanroom requirements.

2.1.5 Sustainability

- Recyclability >95%; recycled aluminum uses only 5% of the energy needed for primary production.

- Meets LEED v4.1 BD+C and GB/T 50378 green building standards for material lifecycle and recycled content.

Best for: Hospitals, pharmaceutical labs, data centers, high-end offices, food processing plants — anywhere hygiene, quiet operation, and longevity matter.

Case Example: Pharmaceutical Cleanroom Upgrade

A manufacturing facility originally used galvanized steel AC vent covers. After 18 months, rust flakes contaminated the cleanroom, causing particle counts to spike to ISO Class 8. Replacing them with anodized aluminum AC vent covers eliminated all corrosion issues. Over three years, particle levels remained consistently at ISO Class 7, and the facility passed its GMP audit without findings. Total cost of ownership dropped 41% over ten years despite a 22% higher initial investment.

2.2 304 / 316 Stainless Steel: The Ultimate Choice for Extreme Environments

Austenitic stainless steels offer unmatched durability in aggressive environments. 304 stainless (UNS S30400) contains 18% chromium and 8% nickel — suitable for general industrial use. 316 stainless (UNS S31600) adds 2–3% molybdenum, dramatically improving resistance to pitting and crevice corrosion — especially in chloride-rich settings.

2.2.1 Key Performance Comparison

| PROPERTY | 304 STAINLESS | 316 STAINLESS |

|---|---|---|

| Density (g/cm³) | 7.93 | 8.00 |

| Tensile Strength (MPa) | ≥515 | ≥520 |

| Yield Strength (MPa) | ≥205 | ≥210 |

| Salt Spray Resistance (h) | 500–800 | 1,500–2,000+ |

| Molybdenum Content (%) | ≤0.75 | 2.0–3.0 |

316 stainless has a Critical Pitting Temperature (CPT) of over 25°C in 3.5% NaCl solution — far higher than 304’s 5–10°C. This makes it the only viable choice for coastal facilities, swimming pools, or chemical plants.

2.2.2 Fabrication and Installation Notes

- Cut edges must be passivated to remove free iron and restore the passive chromium oxide layer.

- Avoid contact with carbon steel tools — cross-contamination can cause localized rust stains.

- Use non-metallic washers or stainless fasteners to prevent galvanic corrosion.

2.2.3 Sustainability

- Fully recyclable with no loss of properties.

- Carbon footprint: 16–20 kg CO₂e/kg (China Building Materials Carbon Emission Guide) — higher than aluminum, but lower than most plastics.

Best for: Chemical plants, offshore platforms, swimming pool HVAC, electroplating lines, and food processing lines — anywhere exposure to salt, acids, or chlorides is unavoidable.

Case Example: Data Center on a Coastal Island

A data center located on a high-salt island faced chloride levels >400 mg/m³. Initial proposals used 304 stainless — but NORSOK M-001 modeling showed a 67% probability of pitting within five years. The project switched to 316 stainless with laser-cut, mirror-polished finishes. After 42 months of continuous operation, zero corrosion was detected — setting a new benchmark for reliability in extreme climates.

2.3 Engineered Plastics (PC/ABS): Low Cost, High Risk

Polycarbonate (PC), acrylonitrile butadiene styrene (ABS), and their blends are popular in residential and low-budget commercial units due to low tooling costs, design flexibility, and electrical insulation.

2.3.1 Typical Properties

- Heat deflection temperature (HDT): PC = 135°C, ABS = 95°C, PC/ABS blend = 110–120°C

- Tensile strength: PC = 60–70 MPa, ABS = 40–50 MPa

- Flame rating: Often UL94 V-0 or V-2

2.3.2 Long-Term Drawbacks

- Thermal creep: Under continuous warm air (>50°C), PC/ABS creeps 0.5–1.2% per year — leading to misaligned louvers after 2–3 years.

- UV degradation: Exposure to sunlight causes yellowing, embrittlement, and up to 40% loss in impact strength within 6–12 months.

- Static charge: Surface resistivity >10¹² Ω attracts dust and fibers — cleaning becomes frequent and ineffective.

- Environmental impact: Less than 15% are recycled; incineration risks dioxin emissions.

A 2023 study by the China Academy of Building Research found that in humid southern climates, plastic AC vent covers had an average service life of just 3.2 years — compared to over 10 years for anodized aluminum.

Best for: Residential split systems, temporary offices, low-budget rentals — only where cost is the sole driver and lifespan is not a concern.

2.4 Galvanized Steel: An Outdated Solution

Galvanized steel (DX51D+Z) was once the industry standard. Zinc coating (8–20 μm) provides sacrificial protection against rust.

2.4.1 Short-Term Advantages

- Lowest upfront cost — 50–70% cheaper than aluminum

- High strength (yield strength ≥280 MPa)

- Easy to stamp and form

2.4.2 Long-Term Failures

- Zinc depletion: In humid, sulfur-rich environments, zinc corrodes at 5–10 μm/year. Within 2–3 years, the protective layer is gone.

- White rust: In sealed or high-humidity storage, zinc hydroxide and carbonate form a powdery white residue — unsightly and corrosive.

- Edge corrosion: Cutting or punching destroys the zinc coating, creating galvanic cells that accelerate rust at cut edges.

ASHRAE Guideline 11-2022 explicitly warns: “Galvanized steel should not be used for exposed AC vent covers in non-arid climates unless additional protective coatings are applied.”

Verdict: Only acceptable in dry warehouses or temporary structures. Not recommended for any long-term or mission-critical facility.

Five Common Misconceptions About AC Vent Cover Materials

Misconception 1: “Aluminum corrodes easily — not suitable for humid areas.”

Reality: Anodized aluminum performs better than galvanized steel in 85% RH, 40°C environments for over 1,000 hours. The oxide layer is chemically inert.

Misconception 2: “Stainless steel never rusts.”

Reality: 304 stainless will pit in chloride-rich environments (e.g., near pools or coasts). Always choose 316 for coastal or chemical zones.

Misconception 3: “Plastic is cheaper overall.”

Reality: When you factor in replacement, cleaning, and downtime, plastic’s total cost of ownership (TCO) exceeds metal by 30–50% over five years.

Misconception 4: “AC vent covers are just decorative.”

Reality: Modern AC vent covers are engineered components — integrating seals, mounting slots, and filter supports. Poor design compromises air tightness, hygiene, and system performance.

Performance Comparison: Real-World Test Results

Below are results from third-party testing labs (National Air Conditioning Equipment Quality Supervision & Inspection Center, 2024), following GB/T 10125 and ISO 4628 standards:

| MATERIAL | SALT SPRAY (960H) MASS LOSS (%) | 85°C/85% RH AGING (1000H) DIMENSION CHANGE (%) | SURFACE DEFECT RATING (ISO 4628) |

|---|---|---|---|

| Anodized Aluminum | <0.5 | <0.1 | ≤2 (Minor discoloration) |

| 316 Stainless Steel | <0.1 | <0.05 | 0 (No change) |

| PC/ABS Plastic | 3.2 | 1.8 | 4 (Severe chalking) |

| Galvanized Steel | 6.7 (White rust) | 0.3 | 5 (Large-scale flaking) |

These numbers don’t lie. In harsh conditions, aluminum and stainless steel outperform plastics and galvanized steel by orders of magnitude.

How to Choose the Right Material: A Practical Selection Guide

Use the table below to match material to environment, based on ISO 9223 corrosion levels and GB/T 50033 climate zones.

| APPLICATION CONTEXT | RECOMMENDED MATERIAL | AVOID | KEY CONSIDERATIONS |

|---|---|---|---|

| Hospitals / Cleanrooms | Anodized aluminum or 316 stainless | Plastic | Must meet ISO 14644; non-shedding, sterilizable |

| Data Centers | High-purity aluminum + anodized | Any ferrous material | Non-magnetic, low particle emission, excellent thermal conductivity |

| Coastal / Island Facilities | 316 stainless or thick-film anodized aluminum | Galvanized steel, plastic | Chloride >300 mg/m³ demands high pitting resistance |

| Commercial Offices | Anodized aluminum | Galvanized steel | Balance cost, quiet operation, and aesthetics |

| Industrial Plants (oil mist) | 304 stainless | Plastic | Resists oil, grease, and thermal cycling |

| Residential Homes | Anodized aluminum or PC/ABS | Galvanized steel | Cost-sensitive; moderate performance acceptable |

Installation Best Practices

- Metal AC vent covers: Never install with carbon steel fasteners — use stainless or non-metallic spacers to prevent galvanic corrosion.

- Plastic AC vent covers: Allow 0.5–1.0 mm expansion gap per meter to prevent buckling.

- Cleanroom applications: Always use silicone gaskets with compression clips to ensure airtight seals (≤0.1% leakage at 5 Pa differential).

Maintenance and Lifecycle Costs: The Hidden Economics

| MATERIAL | AVG. CLEANING FREQUENCY (PER YEAR) | EXPECTED LIFESPAN | COMMON FAILURE MODES |

|---|---|---|---|

| Anodized Aluminum | 1–2 | 10+ years | None |

| 316 Stainless Steel | 1 | 15+ years | None |

| PC/ABS Plastic | 3–4 | 3–5 years | Louver warping, yellowing, cracking |

| Galvanized Steel | 2–3 (plus rust removal) | 5–8 years | Rust, flaking, seal failure |

Pro Tip: If rust has already appeared, cleaning and painting with epoxy-zinc primer + polyurethane topcoat may offer temporary relief — but it’s a band-aid. The only permanent fix is replacement with a corrosion-resistant material.

Conclusion: Material Choice Is a Long-Term Investment

AC vent covers may be small, but they are not insignificant. In high-performance environments — hospitals, labs, data centers, and cleanrooms — the material you choose directly impacts indoor air quality, operational reliability, and total cost of ownership.

Anodized aluminum and stainless steel are no longer “premium upgrades.” They are standard requirements for any facility that values longevity, hygiene, and efficiency.

While plastic and galvanized steel may seem cheaper upfront, their hidden costs — frequent replacement, labor-intensive cleaning, downtime, and compliance risks — make them the most expensive options in the long run.

As green building standards and sustainable operations become mandatory, materials that are durable, recyclable, and low-maintenance will dominate the market. Choosing the right AC vent cover isn’t about saving a few dollars today — it’s about ensuring your facility performs reliably, safely, and cost-effectively for decades.

-

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment -

Top Aluminium Profile Manufacturers in China: Leading the Global Market

Top Aluminium Profile Manufacturers in China: Leading the Global Market -

The Evolution of Air Tight Sliding Doors

The Evolution of Air Tight Sliding Doors -

AHU Aluminium Profile: A Comprehensive Guide

AHU Aluminium Profile: A Comprehensive Guide -

The Importance of Choosing the Right Cleanroom Door in Vietnam

The Importance of Choosing the Right Cleanroom Door in Vietnam -

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety -

.jpg) The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities!

The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities! -

Unlock the Possibilities with AJ Manufacturing Doors

Unlock the Possibilities with AJ Manufacturing Doors -

Make a Statement with Manufactured Home Interior Doors!

Make a Statement with Manufactured Home Interior Doors! -

what is aluminum profile? Aluminum Profiles for Your Home is the best option

what is aluminum profile? Aluminum Profiles for Your Home is the best option

-

How to Extend the Life of Your Exterior Steel Door

How to Extend the Life of Your Exterior Steel Door -

What Are the Best Materials for AC Vent Covers

What Are the Best Materials for AC Vent Covers -

Ceiling Vent Covers Labeled Fire-Rated? Here’s How to Verify

Ceiling Vent Covers Labeled Fire-Rated? Here’s How to Verify -

Upgrading Lab Doors: When to Replace vs. When to Retrofit?

Upgrading Lab Doors: When to Replace vs. When to Retrofit? -

Stainless Steel Door vs. Alternatives in Cleanrooms

Stainless Steel Door vs. Alternatives in Cleanrooms -

Ceiling Vent Care Tips to Boost HVAC Efficiency Year Round

Ceiling Vent Care Tips to Boost HVAC Efficiency Year Round -

How Air Dampers Drive Efficiency in High Performance Buildings

How Air Dampers Drive Efficiency in High Performance Buildings -

Why Semiconductor Manufacturing Can’t Function Without Cleanrooms

Why Semiconductor Manufacturing Can’t Function Without Cleanrooms -

How to Select the Right Floor Vent for Cleanrooms

How to Select the Right Floor Vent for Cleanrooms -

How to Clean and Maintain AC Registers for Peak HVAC Performance

How to Clean and Maintain AC Registers for Peak HVAC Performance

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.

Speak Your Mind