What You Need to Know About ISO 6 Cleanroom Standards and Regulations

- By:ren

- 2022-12-05

- 29

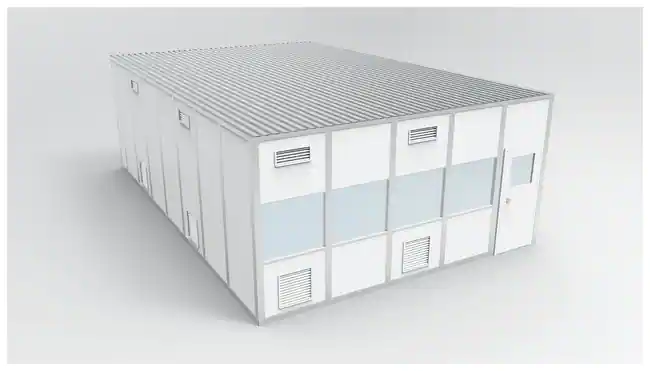

Cleanroom standards and regulations are critical to ensuring safety and quality in a variety of industries, from medical device manufacturing to food packaging. ISO 6, or International Organization for Standardization, is the most widely accepted standard for cleanroom management and operation. ISO 6 sets performance requirements for cleanrooms, such as air pressure, humidity, temperature, and air exchange rate, as well as the materials used for the construction of cleanrooms. ISO 6 also outlines the requirements for personnel and the development of a contamination control program. Adherence to ISO 6 cleanroom standards and regulations is essential to the safety and quality of products and services provided by organizations. Therefore, it is important to understand the details of ISO 6 and the implications of non-compliance.

What is ISO 6 Cleanroom?

ISO 6 describes the minimum air quality and cleanliness standards for rooms used for manufacturing, processing, or medical applications. ISO 6 also outlines the requirements for personnel and the development of a contamination control program. ISO stands for the International Organization for Standardization and 6 is the number assigned to the Standard for Cleanrooms and Cleanrooms Agricultural Buildings. ISO 6 is the most widely accepted standard for cleanroom management and operation. It is a general cleanroom standard that can be applied for most cleanrooms. This means that individual organizations can determine the best way to meet the requirements of the ISO 6 standard for their specific situation and operations. ISO 6 cleanrooms are designed to protect the environment, product, and personnel from pathogens and other contaminants, such as dust and bacteria, that could otherwise negatively affect the quality of products or services. ISO 6 cleanrooms are different from general clean areas, such as kitchens and bathrooms, because they are designed to have very low levels of dust, microbes, and other contaminants.

Benefits of ISO 6 Cleanroom

ISO 6 describes the minimum air quality and cleanliness standards for rooms used for manufacturing, processing, or medical applications. Benefits of ISO 6 include the following: - Protecting the environment, product, and personnel from pathogens and other contaminants - ISO 6 cleanrooms are designed to protect the environment, product, and personnel from microbes and other contaminants, such as dust and bacteria, that could otherwise negatively affect the quality of products or services. - Standardizing cleanroom design, operation, and maintenance - The ISO 6 standard outlines minimum requirements for cleanroom design, operation, and maintenance. Organizations can then design their specific cleanrooms to meet these minimum requirements. - Providing flexibility for a variety of organizations - ISO 6 is a general cleanroom standard that can be applied for most cleanrooms. This means that individual organizations can determine the best way to meet the requirements of the ISO 6 standard for their specific situation and operations. - Communicating cleanroom requirements - ISO 6 cleanroom standards and regulations are critical to ensuring safety and quality in a variety of industries, including medical device manufacturing, pharmaceutical production, food packaging, research, and laboratory settings.

Adherence to ISO 6 standards Cleanroom

ISO 6 cleanrooms are designed to protect the environment, product, and personnel from microbes and other contaminants that could otherwise negatively affect the quality of products or services. Therefore, it is important to understand the details of ISO 6 and the implications of non-compliance. Adherence to ISO 6 standards includes the following: - Understanding the details of ISO 6 - It is important to understand the ISO 6 standard and its requirements for cleanroom design, operation, and maintenance so that organizations can design their specific cleanrooms to meet these minimum requirements. - Considering the organizational implications of non-compliance - Organizations must also consider the organizational implications of non-compliance with ISO 6 standards. For example, a product manufactured in a non-compliant cleanroom may not meet the requirements of a customer.

Overview of ISO 6 performance requirements

ISO 6 cleanrooms are designed to protect the environment, product, and personnel from microbes and other contaminants that could otherwise negatively affect the quality of products or services. Performance requirements outlined by the ISO 6 standard include the following: - Air pressure - Air pressure within a cleanroom is often below the outside pressure to prevent outside contaminants from entering the room. - Air flow rate - The air flow rate is the amount of air that is exchanged in the room per hour. - Humidity - Humidity within a cleanroom is often below 50 percent relative humidity to prevent the growth of mold and bacteria. - Temperature - Temperature within a cleanroom is often below 27 degrees Celsius to prevent the growth of bacteria. - Level of contamination - The level of contamination in a room is determined by the amount of microbes in the room.

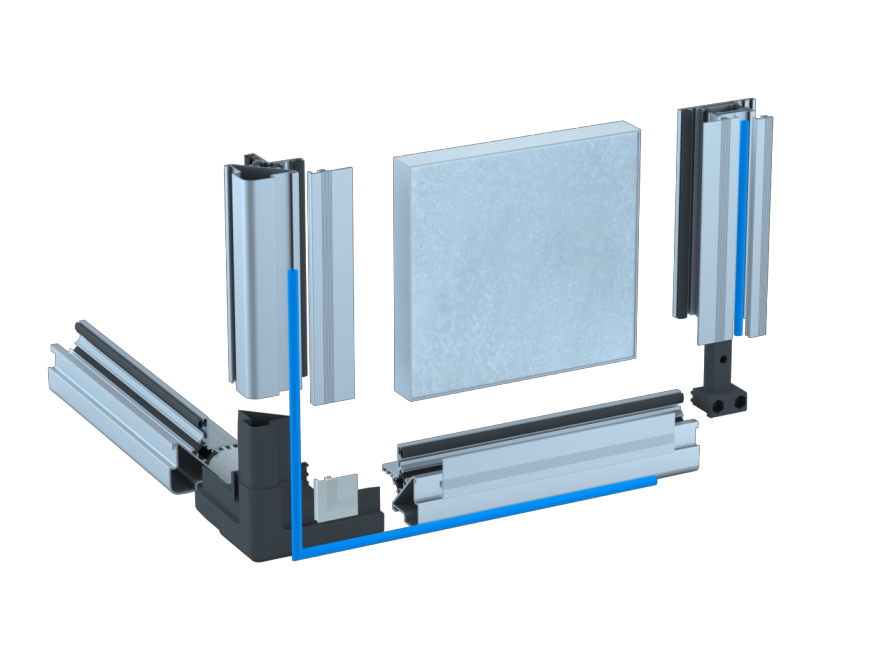

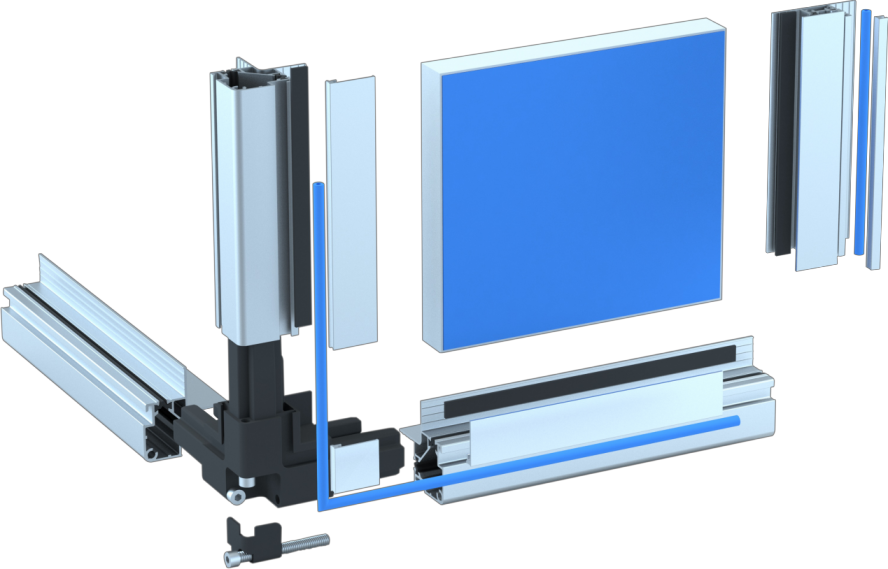

Materials used for cleanroom construction

The ISO 6 standard outlines materials used for cleanroom construction. These materials include the following: - Floor - Floors should be designed with smooth, non-porous surfaces, such as concrete or stainless steel, to prevent the growth of pathogens. - Walls and ceilings - Walls and ceilings should be designed with smooth, non-porous surfaces, such as stainless steel, to prevent the growth of pathogens. - Doors and windows - Doors and windows should be designed with smooth, non-porous surfaces, such as steel, to prevent the growth of pathogens. - Floors and walls - Floors and walls should be designed with smooth, non-porous surfaces, such as steel or concrete, to prevent the growth of pathogens.

Personnel requirements

ISO 6 cleanrooms are designed to protect the environment, product, and personnel from microbes and other contaminants that could otherwise negatively affect the quality of products or services. Personnel requirements outlined by the ISO 6 standard include the following: - Vaccinations - Persons who work in a cleanroom should have up-to-date vaccinations, such as influenza and hepatitis, to minimize the risk of infection and contamination. - Clothing - Persons who work in a cleanroom should wear clothing that minimizes the risk of contaminating products and the cleanroom. - Head, hand, and foot protection - Heads, hands, and feet are the primary sources of contamination on the body and should be protected to minimize the risk of contamination. - Other sources of contamination - Other sources of contamination in the cleanroom should be minimized, such as animals and plants, to prevent the risk of contamination.

Development of a contamination control program

ISO 6 cleanrooms are designed to protect the environment, product, and personnel from microbes and other contaminants that could otherwise negatively affect the quality of products or services. Contamination control programs are developed to address potential sources of contamination in a cleanroom. The ISO 6 standard outlines the following elements of a contamination control program: - Risks - Risks for contamination in a cleanroom should be identified and assessed to determine the best ways to minimize the risk of contamination. - Controls - Controls should be implemented to minimize the risk of contamination. - Monitoring - Monitoring should be implemented to measure the effectiveness of the controls and identify adjustments needed to improve the effectiveness of the controls. - Review - The effectiveness of the controls and the contamination control program should be reviewed periodically to ensure that the program is still effective.

Implications of non-compliance

ISO 6 cleanrooms are designed to protect the environment, product, and personnel from microbes and other contaminants that could otherwise negatively affect the quality of products or services. However, these rooms are different from general clean areas, such as kitchens and bathrooms, because they are designed to have very low levels of dust, microbes, and other contaminants. Therefore, it is important to understand the details of ISO 6 and the implications of non-compliance. Non-compliance with ISO 6 standards may result in the following: - Product recalls - Products manufactured in a non-compliant cleanroom may not meet the requirements of a customer and will most likely result in a product recall. - Unsafe working conditions - Non-compliant cleanrooms may have unsafe working conditions that lead to accidents and injuries. - Environmental issues - Non-compliant cleanrooms may result in environmental issues, such as water and soil contamination.

Resources for ISO 6 compliance

ISO 6 cleanroom standards and regulations are critical to ensuring safety and quality in a variety of industries, from medical device manufacturing to food packaging. ISO 6 cleanrooms are designed to protect the environment, product, and personnel from microbes and other contaminants that could otherwise negatively affect the quality of products or services. However, these rooms are different from general clean areas, such as kitchens and bathrooms, because they are designed to have very low levels of dust, microbes, and other contaminants. Organizations can achieve ISO 6 compliance by understanding the details of the ISO 6 standard and the implications of non-compliance. END

-

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment -

Top Aluminium Profile Manufacturers in China: Leading the Global Market

Top Aluminium Profile Manufacturers in China: Leading the Global Market -

The Evolution of Air Tight Sliding Doors

The Evolution of Air Tight Sliding Doors -

AHU Aluminium Profile: A Comprehensive Guide

AHU Aluminium Profile: A Comprehensive Guide -

The Importance of Choosing the Right Cleanroom Door in Vietnam

The Importance of Choosing the Right Cleanroom Door in Vietnam -

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety -

.jpg) The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities!

The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities! -

Unlock the Possibilities with AJ Manufacturing Doors

Unlock the Possibilities with AJ Manufacturing Doors -

Make a Statement with Manufactured Home Interior Doors!

Make a Statement with Manufactured Home Interior Doors! -

what is aluminum profile? Aluminum Profiles for Your Home is the best option

what is aluminum profile? Aluminum Profiles for Your Home is the best option

-

Guide to Doors Clean Room: Ensuring Contamination Control

Guide to Doors Clean Room: Ensuring Contamination Control -

Introducing Guangdong Clean Room Aluminum Company: E-ZONG

Introducing Guangdong Clean Room Aluminum Company: E-ZONG -

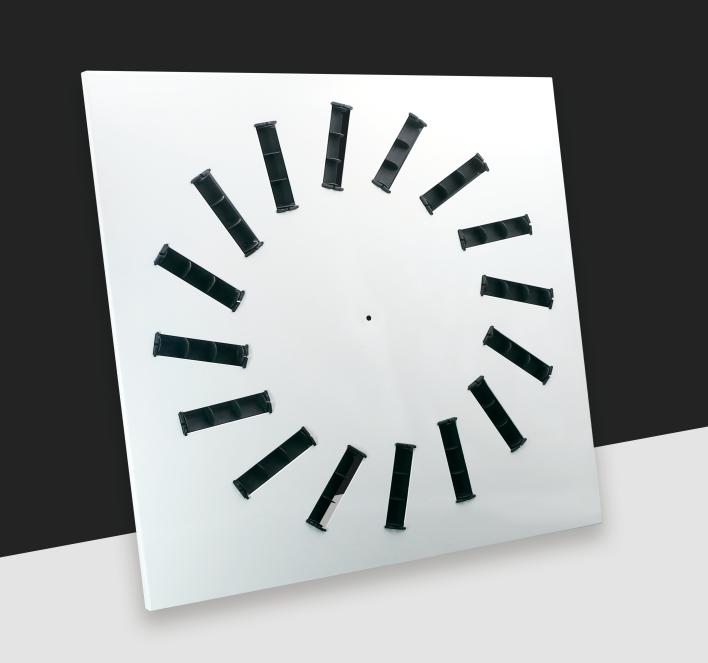

Cost-Effectiveness of Bulk Purchasing Air Diffuser

Cost-Effectiveness of Bulk Purchasing Air Diffuser -

Makeup Air Handling Unit: Here to Know

Makeup Air Handling Unit: Here to Know -

Customizing HVAC Systems Parts for Building Specific Needs

Customizing HVAC Systems Parts for Building Specific Needs -

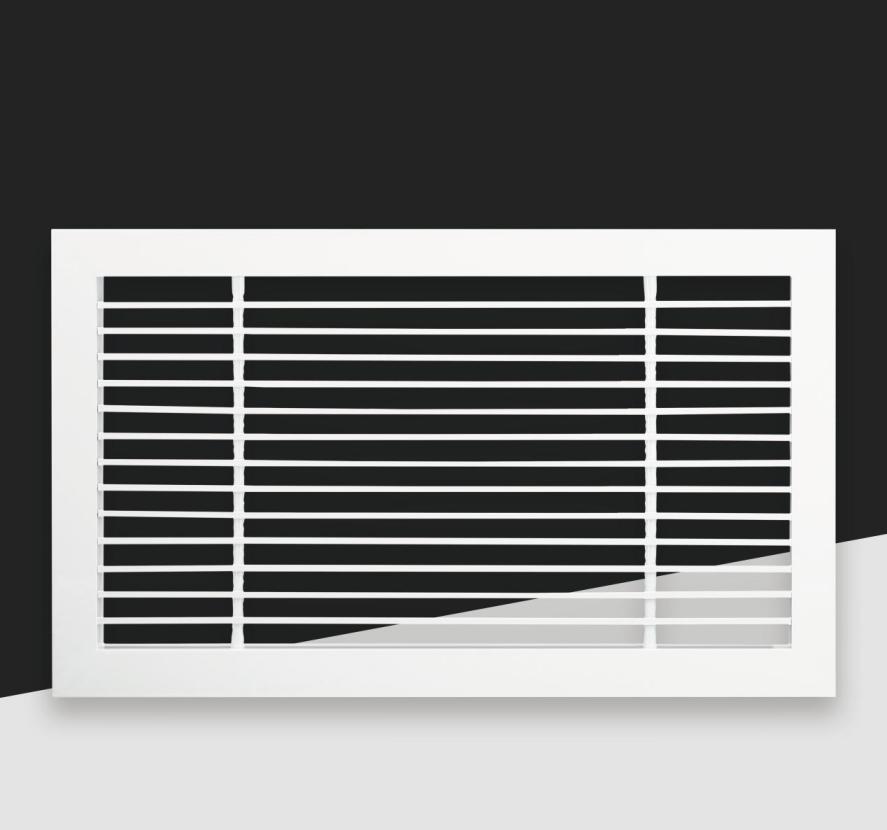

How Return Air Diffuser Enhances HVAC Efficiency for Your Projects

How Return Air Diffuser Enhances HVAC Efficiency for Your Projects -

Exploring the Versatility of Swing Glass Door

Exploring the Versatility of Swing Glass Door -

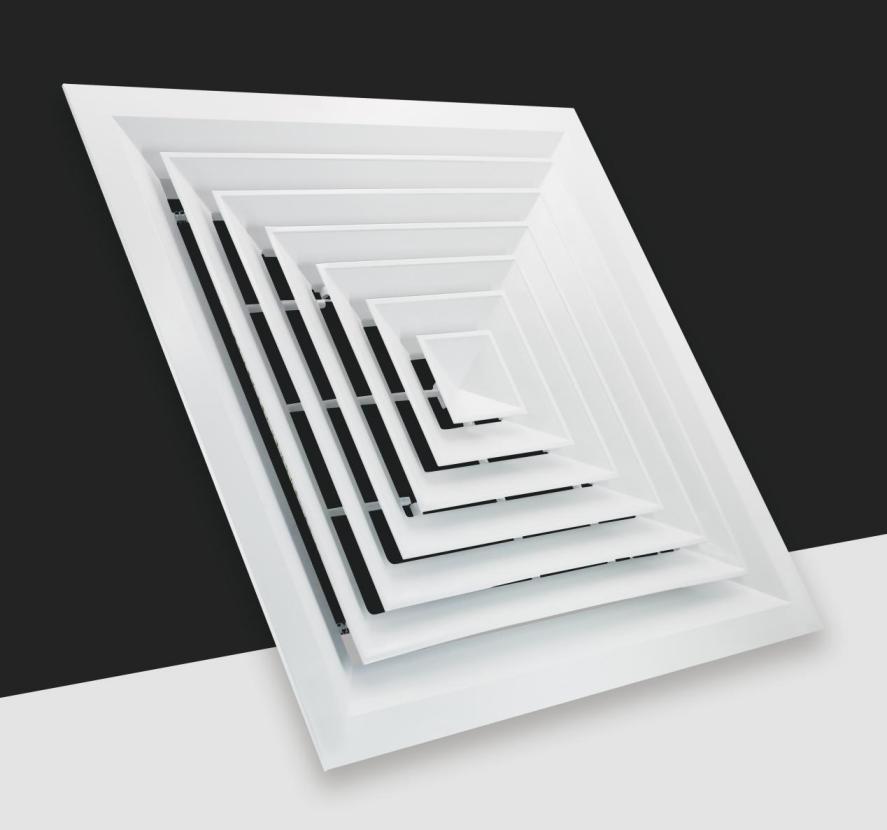

Choosing Quality: Why Linear Diffuser Grille is Essential in Modern Design

Choosing Quality: Why Linear Diffuser Grille is Essential in Modern Design -

Introduction to Clean Room High Speed Doors: Let’s Dive into

Introduction to Clean Room High Speed Doors: Let’s Dive into -

High-Quality Clean Room Double Door for Medical and Health

High-Quality Clean Room Double Door for Medical and Health

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.

Speak Your Mind