How to Choose the Right Pharmaceutical Clean Doors for Your Hospital

- By:ren

- 2022-11-30

- 29

In the modern workplace, the importance of maintaining a hygienic environment cannot be overstated. It is essential for businesses to ensure that proper hygiene levels are maintained to safeguard the health of their staff, customers, and visitors. One of the most effective ways to do this is to install pharmaceutical clean doors. These specialized doors are designed to maintain high levels of hygiene in the workplace, providing a safer and healthier atmosphere for everyone. Pharmaceutical clean doors can help to reduce the spread of germs, viruses, and other contaminants, and can also help to maintain a higher level of air quality in the workplace. By implementing a system of pharmaceutical clean doors, businesses can ensure that their staff, customers, and visitors are safe and healthy, creating a much healthier and more productive workplace.

What are pharmaceutical clean doors?

Pharmaceutical clean doors are a type of specialized doors designed to maintain high levels of hygiene—in fact, they’re the highest level of cleanliness that exists on the ISO cleanliness scale. Pharmaceutical clean doors are the best option for businesses looking to maintain a very high level of cleanliness, ensuring that the entire workplace can be kept in a state of pharmaceutical cleanliness. These doors are often used in hospitals and laboratories, where the risk of pathogens and contaminants is high. Pharmaceutical clean doors can be used in any environment where high levels of cleanliness are required, and are often found in food processing, pharmaceutical, and medical facilities. Pharmaceutical clean doors are designed to a high standard, with many safety and hygiene features. They have a smooth, easy-to-clean surface, and can be made from a variety of materials such as stainless steel, plastic, and glass. Pharmaceutical clean doors are strong enough to withstand heavy traffic and daily use, and are often made with automatic or remote-controlled hinges to reduce the risk of manual contamination.

Benefits of using pharmaceutical clean doors

Installing a system of pharmaceutical clean doors can result in many benefits for the workplace. Pharmaceutical clean doors can help to limit the spread of pathogens, increasing the safety of workers and visitors. They can also help to reduce the spread of airborne contaminants, limiting the risk of allergies and respiratory problems among staff, customers, and visitors. Pharmaceutical clean doors can also help to maintain a higher level of air quality, protecting the health and comfort of all staff. When the air quality is lower, staff can experience fatigue, headaches, and difficulty concentrating. Additionally, a lower quality of air can increase the risk of flu infections among staff members, and allergic reactions among customers, visitors, and staff. By installing a system of pharmaceutical clean doors, businesses can ensure that they maintain a much higher level of air quality to protect the health of everyone in their workplace.

Different types of pharmaceutical clean doors

There are many different types of pharmaceutical clean doors available, including sliding and swinging doors, sliding security doors, and bi-fold doors. Sliding pharmaceutical clean doors are most commonly used in laboratories and clean rooms, as they offer added protection against drafts. Swinging pharmaceutical clean doors are more commonly used in hospitals, as they are easier to regulate with regards to air flow. Sliding security pharmaceutical clean doors are designed to keep people out of restricted areas, while bi-fold pharmaceutical clean doors can be opened in a variety of ways to regulate the flow of people and air.

Hygiene standards and regulations

When installing pharmaceutical clean doors, it is important to meet certain hygiene standards and regulations. In order to maintain a high level of cleanliness, businesses need to be mindful of the amount of bacteria present in the air, as well as the amount of bacteria on door and surface areas. The amount of bacteria in the air can be determined by measuring the concentration of particulate matter. It is recommended that the concentration of particulate matter be kept below 10 CFU/m3 (colony forming units per cubic meter), and that the amount of bacteria on door and surface areas be kept below 100 cfu/cm2. Pharmaceutical clean doors help to reduce the amount of bacteria in the air, as well as on surfaces, further reducing the risk of cross-contamination.

Installing and maintaining pharmaceutical clean doors

Installing pharmaceutical clean doors can be a simple and effective way to maintain high levels of cleanliness in a workplace. To help reduce the risk of contamination, it is important to keep the following tips in mind: Use clean and disinfected tools when installing pharmaceutical clean doors. These tools should be cleaned with an appropriate solution before each installation. Ensure that the surfaces that come into contact with the pharmaceutical clean doors are clean and dry. This includes the doorframes and the surfaces that the pharmaceutical clean doors sit against. Ensure that the pharmaceutical clean doors are properly maintained. This includes cleaning and disinfecting the doors regularly, and replacing any worn out sections as necessary. When installing pharmaceutical clean doors, it is important to keep in mind the direction of the open and close cycle. The open cycle is the time during which the door is in motion when it is opened, and the close cycle is the time during which the door is in motion when it is closed. When installing pharmaceutical clean doors, it is important to keep in mind the direction of the open and close cycle so that they are installed correctly. When maintaining pharmaceutical clean doors, it is important to keep the following tips in mind: Clean the surfaces of the pharmaceutical clean doors regularly. This includes the hinges, track, and opening mechanisms. Clean the surfaces that come into contact with the pharmaceutical clean doors regularly. This includes the doorframes and the areas where the pharmaceutical clean doors sit against. Regularly disinfect the pharmaceutical clean doors. This includes cleaning the door surfaces with an appropriate disinfecting solution, and wiping down the door and frame surfaces with a disinfectant solution. It is important to maintain a high level of cleanliness when installing and maintaining pharmaceutical clean doors to help reduce the risk of cross-contamination.

The importance of air quality in the workplace

Air quality is a crucial factor in maintaining a healthy and productive workplace. Poor air quality can lead to a wide range of health issues, including allergies, respiratory problems, and fatigue. Additionally, low air quality can make employees less productive, as they may experience difficulty concentrating or even feel too uncomfortable to perform at their best. It is important to implement practices and equipment to help improve the air quality in the workplace, including the use of pharmaceutical clean doors. When air quality is lower, it contains more particles, including bacteria, allergens, and other contaminants. When air particles are above normal levels, they can affect the health of those in the workplace, causing problems such as allergies, respiratory issues, and cognitive impairment. By reducing the amount of contaminants in the air, businesses can improve the overall air quality of the workplace, protecting the health and productivity of their staff.

Ensuring a hygienic work environment

When it comes to protecting the health of your customers and visitors, it is important to ensure that your business maintains a hygienic environment. This means that every surface and item in the workplace must be kept clean and free of contaminants. Pharmaceutical clean doors are designed to provide the highest level of cleanliness, and are the best option for businesses looking to maintain a very high level of hygiene. These specialized doors are designed to reduce the risk of cross-contamination, keeping everything in the workplace clean and safe. When the environment is kept clean and free of contaminants, everyone is much less likely to get sick, and everyone can go home feeling healthy and happy. When a business uses pharmaceutical clean doors, they can help to reduce the risk of cross-contamination, keeping everything in the workplace clean and safe.

Cost-effectiveness of pharmaceutical clean doors

One of the best things about pharmaceutical clean doors is that they are cost-effective. Installing a system of pharmaceutical clean doors helps to protect the health and safety of both employees and visitors, as well as protecting the investment made in high-end machinery and equipment. Pharmaceutical clean doors can help to reduce the risk of cross-contamination, as well as the risk of damage caused by cleaning chemicals. Pharmaceutical clean doors can help to extend the lifespan of expensive machinery and equipment, protecting the investment made in these items. Additionally, pharmaceutical clean doors can help to reduce the risk of legal action against your business, as they help to protect the health and safety of your employees and visitors. Pharmaceutical clean doors are designed to help reduce the risk of cross-contamination, keeping the workplace clean and safe for everyone. By implementing a system of pharmaceutical clean doors, businesses can ensure that visitors and employees are safe and healthy, creating a much healthier and more productive work

-

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment

-

Top Aluminium Profile Manufacturers in China: Leading the Global Market

-

The Evolution of Air Tight Sliding Doors

-

AHU Aluminium Profile: A Comprehensive Guide

-

The Importance of Choosing the Right Cleanroom Door in Vietnam

-

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety

-

The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities!

-

Unlock the Possibilities with AJ Manufacturing Doors

-

Make a Statement with Manufactured Home Interior Doors!

-

what is aluminum profile? Aluminum Profiles for Your Home is the best option

-

High Speed Clean Room Doors Cut Contamination Risk

-

Dustproof Cleanroom Door Innovation for Sterile Spaces

-

How Cleanroom Half Glass Swing Door Enhances Sterile Access

-

Why Custom Cleanroom Aluminum Profile Matters Today

-

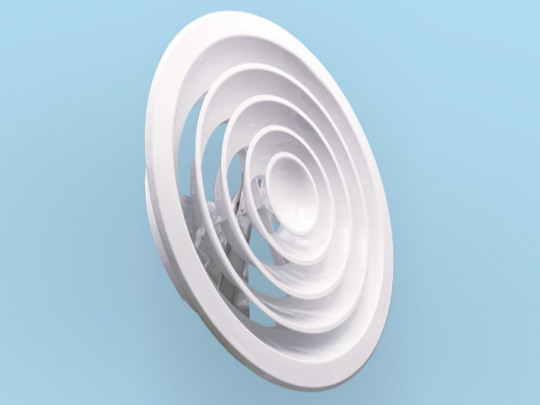

Smart Ceiling Air Diffuser: Dampers Add Full Control

-

E-ZONG: Trusted Air Tight Sliding Cleanroom Door Manufacturer

-

Top Benefits of Clean Room Roll Up Door Systems

-

Cleanroom Glass Door Innovations You Should Know

-

Improve Airflow With the Right Air Diffuser Vent

-

Why Every Laboratory Needs a Sealed Cleanroom Door

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.

.jpg)

Speak Your Mind