How Air Dampers Drive Efficiency in High Performance Buildings

- By:Lisa

- 2025-10-30

- 29

In today’s high-performance buildings—from academic medical centers and biosafety labs to data centers and Class A offices—the HVAC system is no longer just about comfort. It’s the backbone of safety, compliance, and operational continuity. Yet this critical infrastructure comes at a steep price: HVAC accounts for 40–60% of total energy use in commercial buildings. In healthcare facilities, that figure often exceeds 55%.

The good news? One of the most effective levers for reducing that load is also one of the most overlooked: the air damper.

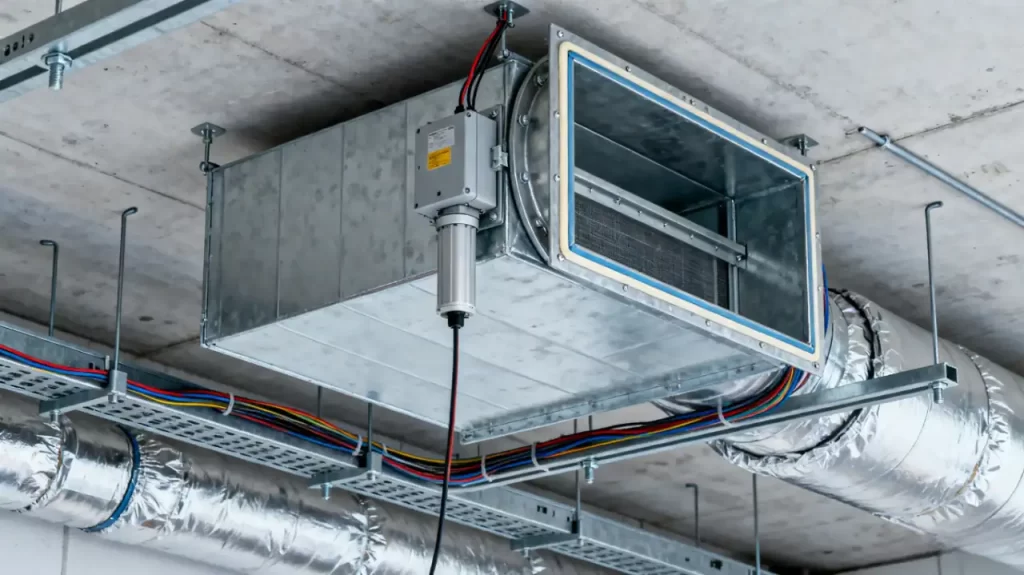

Far from being a simple on/off valve, modern motorized air dampers, driven by reliable air damper actuators, enable precise airflow modulation, dynamic pressure control, and intelligent energy management. And when seamlessly integrated with high-performance aluminum components—like aluminum supply grilles, HVAC diffusers, and custom framing—their impact multiplies.

1. Why High-Stakes Environments Demand Smarter Dampers

Precision Pressure Control

Operating rooms must maintain +8 Pa positive pressure, with fluctuations held to ±2.5 Pa—even when doors open. This requires pressure control dampers for medical facilities that respond in seconds. Similarly, air dampers for negative pressure rooms keep BSL-3 labs safely contained at –30 Pa.

High Air Change Rates

ISO Class 5 cleanrooms demand 300–600 air changes per hour (ACH). That’s only possible with low leakage dampers for cleanrooms that meet AMCA Class I standards (≤0.1% leakage @ 1000 Pa). In labs, laboratory fume hood exhaust dampers dynamically adjust to sash position, maintaining face velocities of 0.4–0.6 m/s.

Long-Term Reliability

These systems must run for 15–20 years with minimal downtime. That’s why modular designs—like aluminum supply grilles with dampers—and digital coordination via BIM models for HVAC dampers are becoming standard.

2. Real-World Impact: Where Dampers Make the Difference

Hospitals: Stabilizing Pressure Without Wasting Energy

Every time an OR door opens, 0.3–0.5 m³ of conditioned air escapes. Without compensation, pressure collapses in seconds.

The fix? Install low leakage dampers for cleanrooms on exhaust branches, linked to door status signals. When the door opens, an automatic damper for cleanroom doors reduces exhaust flow within 1–2 seconds.

Result: One academic medical center saw pressure variation drop from ±4.2 Pa to ±1.8 Pa—and cut HVAC energy use by 18%.

Labs: Safety Meets Efficiency

Modern labs use VAV boxes with integrated dampers that respond in real time. The key is selecting the right modulating damper for exhaust systems—one with ±5% linearity and AMCA-certified leakage performance. Engineers often ask: “How to select an air damper for lab applications?” The answer lies in balancing safety, precision, and serviceability.

Data Centers & Offices

Data center HVAC airflow control relies on duct-mounted air damper actuators to isolate hot and cold aisles. Meanwhile, energy-efficient dampers for commercial HVAC enable zoned comfort in premium offices—supporting LEED and WELL certifications.

3. Four Ways Dampers Save Energy

- Cubic Savings from Fan Laws Fan power scales with the cube of airflow. Reduce airflow to 70% with a motorized air damper for VAV systems, and power drops to just 34%. One 50,000 m² office saved over 500,000 kWh/year.

- Eliminate Over-Pressurization Traditional systems run at 120% airflow “just in case.” Smart control via HVAC dampers with aluminum frames cuts total supply air by 19% annually.

- Maximize Free Cooling During mild weather, economizer dampers for free cooling bring in filtered outdoor air—bypassing chillers entirely. But this only works if the aluminum-framed damper for AHUs is truly airtight.

- Simplify Commissioning & Maintenance

- HVAC system balancing with dampers ensures design intent is met.

- Aluminum diffusers with built-in dampers allow maintenance in under two minutes.

- Always include a damper leakage test for HVAC systems during commissioning.

4. The Integration Advantage: Why Aluminum Matters

It’s not just what damper you choose—it’s how it fits.

- Precision Fit: Standardized interfaces between HVAC dampers and aluminum frames eliminate field modifications and leakage paths.

- Airtight Sealing: Mechanical gaskets (not silicone) ensure compliance with fire/smoke damper hospital code requirements like NFPA 90A.

- Smart Coordination: Link HVAC damper control to building automation systems for real-time optimization. Use low-torque dampers for small ducts where space is tight.

- Future-Proofing: Enable damper coordination with automatic doors to maintain pressure during peak traffic.

5. Practical Recommendations

- Specify AMCA-certified dampers in all critical applications.

- Prioritize energy-saving air dampers for commercial buildings in early design.

- Choose aluminum return air grilles with dampers for clean aesthetics and performance.

- Require BIM-ready assemblies to reduce coordination errors and speed up installation.

Frequently Asked Questions

Q: How do I select an air damper for a laboratory?

A: Look for a modulating damper for exhaust systems with ≤±5% linearity, AMCA Class I leakage rating, and BMS compatibility. Always validate against your risk assessment.

Q: What damper specs are needed for an ISO Class 5 cleanroom?

A: Use low leakage dampers for cleanrooms with ≤0.1% leakage, smooth internal surfaces, and non-shedding finishes—ideally a precision airflow damper for cleanroom ISO 5.

Q: How can aluminum grilles integrate with dampers?

A: Opt for aluminum supply grilles with dampers pre-installed, or ensure standardized mounting interfaces—no field cutting or sealing required.

Q: What codes govern dampers in hospitals?

A: Comply with fire/smoke damper hospital code standards like NFPA 90A and ASHRAE 170. Ensure automatic dampers for cleanroom doors support ±2.5 Pa stability.

Q: How is damper leakage tested?

A: Perform a damper leakage test for HVAC systems per AMCA 500-D at 1000 Pa. For critical spaces, accept only ≤0.1% leakage (AMCA Class I).

-

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment -

Top Aluminium Profile Manufacturers in China: Leading the Global Market

Top Aluminium Profile Manufacturers in China: Leading the Global Market -

The Evolution of Air Tight Sliding Doors

The Evolution of Air Tight Sliding Doors -

AHU Aluminium Profile: A Comprehensive Guide

AHU Aluminium Profile: A Comprehensive Guide -

The Importance of Choosing the Right Cleanroom Door in Vietnam

The Importance of Choosing the Right Cleanroom Door in Vietnam -

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety -

.jpg) The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities!

The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities! -

Unlock the Possibilities with AJ Manufacturing Doors

Unlock the Possibilities with AJ Manufacturing Doors -

Make a Statement with Manufactured Home Interior Doors!

Make a Statement with Manufactured Home Interior Doors! -

what is aluminum profile? Aluminum Profiles for Your Home is the best option

what is aluminum profile? Aluminum Profiles for Your Home is the best option

-

How to Extend the Life of Your Exterior Steel Door

How to Extend the Life of Your Exterior Steel Door -

What Are the Best Materials for AC Vent Covers

What Are the Best Materials for AC Vent Covers -

Ceiling Vent Covers Labeled Fire-Rated? Here’s How to Verify

Ceiling Vent Covers Labeled Fire-Rated? Here’s How to Verify -

Upgrading Lab Doors: When to Replace vs. When to Retrofit?

Upgrading Lab Doors: When to Replace vs. When to Retrofit? -

Stainless Steel Door vs. Alternatives in Cleanrooms

Stainless Steel Door vs. Alternatives in Cleanrooms -

Ceiling Vent Care Tips to Boost HVAC Efficiency Year Round

Ceiling Vent Care Tips to Boost HVAC Efficiency Year Round -

How Air Dampers Drive Efficiency in High Performance Buildings

How Air Dampers Drive Efficiency in High Performance Buildings -

Why Semiconductor Manufacturing Can’t Function Without Cleanrooms

Why Semiconductor Manufacturing Can’t Function Without Cleanrooms -

How to Select the Right Floor Vent for Cleanrooms

How to Select the Right Floor Vent for Cleanrooms -

How to Clean and Maintain AC Registers for Peak HVAC Performance

How to Clean and Maintain AC Registers for Peak HVAC Performance

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.

Speak Your Mind