Sealing the Flavor: Food Processing Doors

- By:hqt

- 2023-12-04

- 29

Food processing doors stand as essential components within the food industry, assuming a pivotal role in preserving the integrity of food products. Far beyond simple barriers, these doors act as staunch sentinels, diligently upholding safety, quality, and efficiency within food processing facilities. Their fundamental objective revolves around the maintenance of an immaculate and hygienic environment, wherein food processing can occur devoid of contamination risks. Within an industry that prizes the utmost standards of cleanliness and product excellence, food processing doors emerge as the initial line of defense. They staunchly thwart the ingress of external contaminants, guarantee precise temperature and humidity control, and seamlessly facilitate the flow of operations. In their absence, these specialized doors, the entire food production process would stand exposed to vulnerabilities, imperiling the industry's unwavering commitment to quality and safety.

Types of Food Processing Doors

Food processing facilities rely on various types of doors to meet specific operational requirements:

Freezer Room Doors

Freezer room doors are designed to insulate and maintain low temperatures, ensuring the preservation of frozen goods. These doors incorporate advanced insulation materials and sealing mechanisms to minimize energy consumption and maintain the integrity of frozen products.

Cleanroom Doors

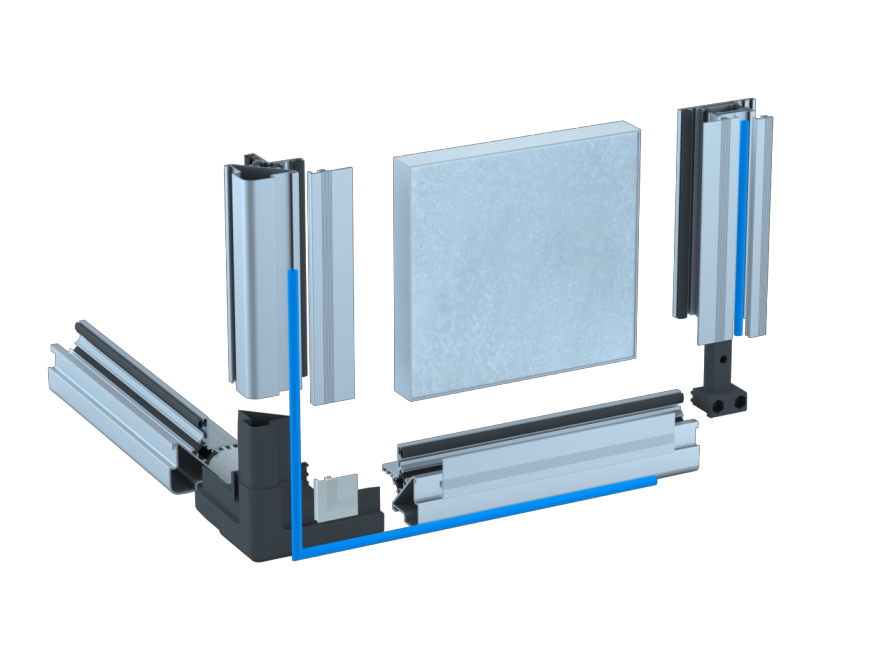

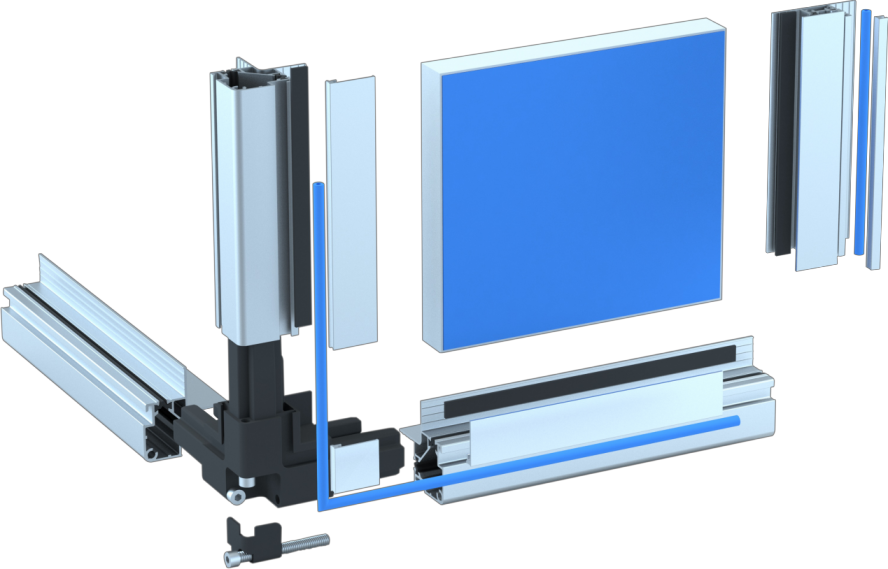

Cleanroom doors are crucial in maintaining sterile environments, particularly in the pharmaceutical and biotech industries. They are constructed with materials that minimize particle generation and ensure controlled airflow to prevent contamination.

Other Specialized Doors

Other specialized doors include blast freezer doors, which enable rapid cooling and preservation of perishable items, and airlock doors, which manage airflow to enhance hygiene and safety during personnel and material transfer.

Key Features of Food Processing Doors

Airtight Seals

Airtight seals are essential to prevent the infiltration of contaminants and maintain controlled environments. These seals utilize specific gasket materials and sealing mechanisms to ensure a secure barrier.

Easy Cleaning and Maintenance

Food processing doors should have smooth surfaces and seamless joints to facilitate easy cleaning and sanitation. Accessibility for inspection and repairs is crucial to uphold hygiene standards.

Resistance to Moisture, Chemicals, and Temperature Fluctuations

Food processing environments are often exposed to moisture, chemicals, and temperature variations. Doors must be designed to resist corrosion and deterioration, using suitable materials and coatings.

Durability and Longevity

The durability of food processing doors is critical, as they are subjected to frequent use and potential wear and tear. Choosing doors that can withstand these conditions and have a longer lifespan can reduce maintenance costs and enhance overall operational efficiency.

Benefits of Food Processing Doors

Prevention of Contamination

Food processing doors are crucial in preventing contaminant intrusion and maintaining the hygiene and safety of the production environment. Their airtight seals and specialized designs act as barriers against dust, pathogens, and foreign particles, ensuring product quality and compliance with industry standards.

Reduction of Energy Loss

Food processing facilities often require controlled environments with specific temperature and humidity levels. Food processing doors, particularly freezer room doors, are vital in reducing energy loss by providing effective insulation. This results in lower energy consumption and cost savings over time.

Facilitation of Smooth Workflow

Food processing doors are designed to enhance operational efficiency by allowing for the seamless movement of materials, equipment, and personnel. Airlock doors, for example, help maintain separate environments while enabling the efficient transfer of goods, thereby streamlining workflow and minimizing disruptions.

Preservation of Product Integrity and Flavor

Food quality and flavor are paramount in the industry. Food processing doors contribute to product integrity by maintaining optimal processing conditions. Precise temperature and humidity control and contamination prevention help preserve the taste, texture, and overall quality of food products.

Future Trends and Innovations

Emerging Technologies in Food Processing Door Design

The future of food processing doors lies in the integration of advanced technologies. This includes the development of doors equipped with sensors and monitoring systems to ensure real-time data on environmental conditions. Smart door systems may also feature automated opening and closing based on predetermined criteria, enhancing efficiency and reducing human error.

Sustainability and Energy-Efficient Solutions

Sustainability is becoming increasingly important in the food industry. Future food processing doors will likely incorporate eco-friendly materials and energy-efficient designs to align with sustainability goals. This can include energy recovery systems and improved insulation to reduce energy consumption further.

Integration of Automation and Smart Features

Automation is a key trend in the food processing industry, and food processing doors are no exception. Advanced control systems may allow for remote monitoring and operation of doors, enhancing convenience and efficiency. Integration with the broader automation infrastructure of food processing facilities can lead to smoother, more synchronized operations.

As the food industry evolves, food processing doors will play an ever more critical role in maintaining food safety, quality, and efficiency. Embracing emerging technologies and sustainability principles while optimizing automation and smart features will shape the future of food processing door design and functionality, further advancing the industry's capabilities.

To Sum Up

In summary, food processing doors play an essential role as protectors of food safety, quality, and operational efficiency. These purpose-built barriers safeguard against contamination, enhance energy efficiency, optimize workflow, and safeguard the essence of food flavors within the industry. With a commitment to embracing emerging technologies and sustainable practices, the future of food processing doors holds the promise of continued advancements, ensuring the industry's ability to consistently meet and surpass crucial standards while preserving the taste of success.

-

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment -

Top Aluminium Profile Manufacturers in China: Leading the Global Market

Top Aluminium Profile Manufacturers in China: Leading the Global Market -

The Evolution of Air Tight Sliding Doors

The Evolution of Air Tight Sliding Doors -

AHU Aluminium Profile: A Comprehensive Guide

AHU Aluminium Profile: A Comprehensive Guide -

The Importance of Choosing the Right Cleanroom Door in Vietnam

The Importance of Choosing the Right Cleanroom Door in Vietnam -

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety -

.jpg) The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities!

The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities! -

Unlock the Possibilities with AJ Manufacturing Doors

Unlock the Possibilities with AJ Manufacturing Doors -

Make a Statement with Manufactured Home Interior Doors!

Make a Statement with Manufactured Home Interior Doors! -

what is aluminum profile? Aluminum Profiles for Your Home is the best option

what is aluminum profile? Aluminum Profiles for Your Home is the best option

-

Guide to Doors Clean Room: Ensuring Contamination Control

Guide to Doors Clean Room: Ensuring Contamination Control -

Introducing Guangdong Clean Room Aluminum Company: E-ZONG

Introducing Guangdong Clean Room Aluminum Company: E-ZONG -

Cost-Effectiveness of Bulk Purchasing Air Diffuser

Cost-Effectiveness of Bulk Purchasing Air Diffuser -

Makeup Air Handling Unit: Here to Know

Makeup Air Handling Unit: Here to Know -

Customizing HVAC Systems Parts for Building Specific Needs

Customizing HVAC Systems Parts for Building Specific Needs -

How Return Air Diffuser Enhances HVAC Efficiency for Your Projects

How Return Air Diffuser Enhances HVAC Efficiency for Your Projects -

Exploring the Versatility of Swing Glass Door

Exploring the Versatility of Swing Glass Door -

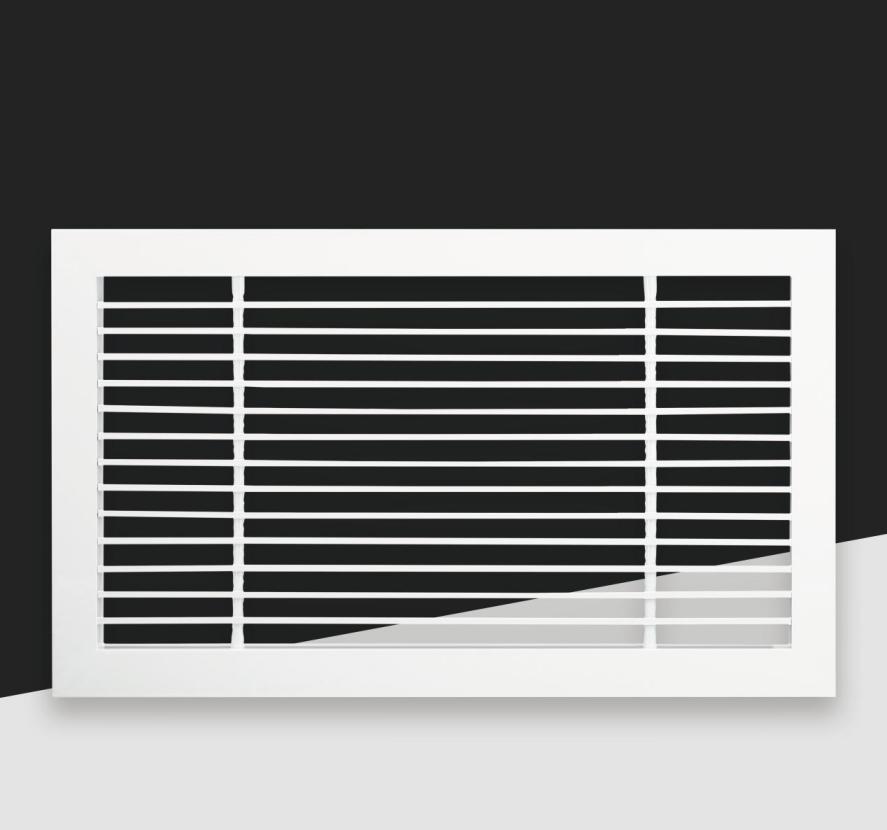

Choosing Quality: Why Linear Diffuser Grille is Essential in Modern Design

Choosing Quality: Why Linear Diffuser Grille is Essential in Modern Design -

Introduction to Clean Room High Speed Doors: Let’s Dive into

Introduction to Clean Room High Speed Doors: Let’s Dive into -

High-Quality Clean Room Double Door for Medical and Health

High-Quality Clean Room Double Door for Medical and Health

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.

Speak Your Mind