Construction Of Modern Cosmetic Clean Room

Cosmetic Clean Room Case Overview

Most modern cosmetics contain proteins, vitamins, amino acids, plant extracts, etc. These components provide favorable conditions for the growth and reproduction of microorganisms such as bacteria and molds and are prone to microbial contamination. Therefore, the construction and production environment of modern cosmetic clean rooms is one of the critical factors affecting the quality of cosmetics.

Case customer profile

Guangzhou Shengko Biotechnology Co., Ltd. is a cosmetic OEM/ODM modern and innovative cosmetic manufacturing enterprise integrating product R&D, production and sales services. It has a 100,000-level dust-free workshop of more than 10,000 square meters, and has passed GMPC and ISO22716 International quality management system certification.

Case pain point/demand analysis

With the development of modern biomedicine, the requirements for the control of the number of bacteria and microbial contamination in the dust-free workshop are also constantly increasing, so as to ensure a good production environment for the medical and pharmaceutical, biological research, food production and other industries. Dust-free workshops are inseparable from the electronics, pharmaceutical, bioengineering, medical and health, food, cosmetics and military industries, providing a controlled environment to meet production needs, which will directly affect the quality of products. The number of bacteria in the clean room workshop and the problem of microbial contamination continue to increase. The first thing to solve is the cleanliness of the clean room workshop, and the use of products is a key point.

Case Solutions

E-ZONG provided Shengko Biotechnology with a clean room door and window solution for building a 100,000-level dust-free workshop, and provided a strong material guarantee for the clean environment required for its cosmetic production.

Finished product rendering

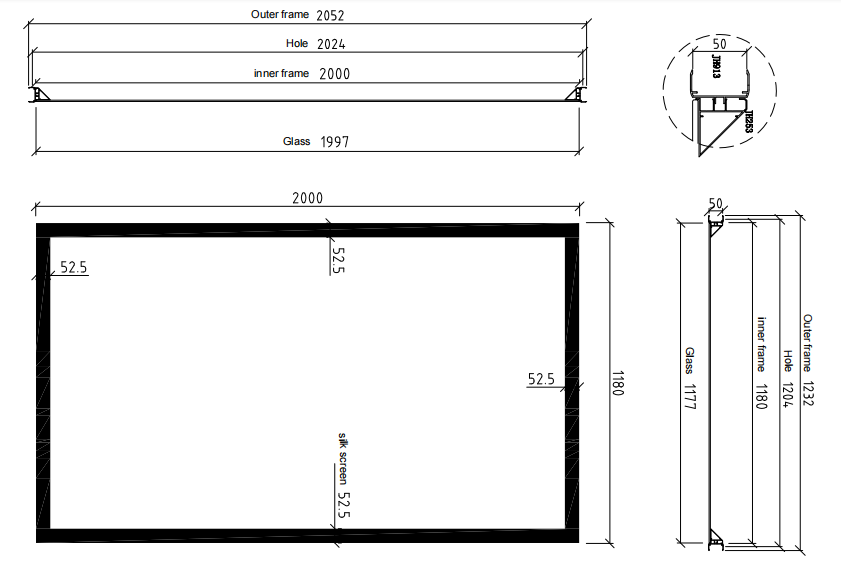

E-ZONG double-layer hollow clean window adopts 5mm thick tempered glass, which is 3-5 times stronger than ordinary glass and not easy to break. When broken by an external force, the fragments will form obtuse-angled fragments similar to honeycombs, reducing the risk of serious injury to the human body. Secondly, nitrogen is filled in the middle of the glass interlayer, and molecular sieve material is added to effectively absorb water vapor and prevent the glass window from fogging due to temperature difference and moisture. The glass windows are clean and bright, with good permeability, which is easy to observe and understand the situation in the workshop. The whole workshop adopts color steel plate clean doors, which are flat and easy to clean, light in weight, anti-collision, soundproof and fireproof, and easy to install. The E-ZONG clean door adopts the fireproof color steel plate that has passed the EU CE certification. At 1000 degrees Celsius, it is effectively flame retardant for 280 minutes, and the fire rating is A2-S2. The door core adopts aviation-grade aluminum honeycomb core material, which has the advantages of light weight, strong compression resistance, sound insulation and noise reduction.

Customer Summary/Evaluation

E-ZONG has been committed to providing customers with high-quality and cost-effective clean door and window solutions, and makes unremitting efforts to create a higher quality and high standard clean space.

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.