Maintaining a sterile environment with the use of cleanroom doors interlocks

- By:ren

- 2022-08-16

- 29

What is meant by cleanroom door interlocks?

- An interlock is a mechanism that delays opening a door until the one before it has been closed. Doing this prevents pollutants from being brought in from outside. Cleanroom door interlocks are crucial to maintaining a cleanroom. Installing them will guarantee the cleanliness of your cleanroom and the purity of your goods.

- The cleanroom environment is created by applying air filtration and pressurization and observing stringent guidelines for attire, tools, and conduct. Making sure the doors are correctly sealed and an efficient interlock mechanism is one of the most crucial parts of maintaining a cleanroom.

The primary purpose of cleanroom doors interlocks:

- These cleanroom doors interlock's primary function is to stop people from bringing pollutants into the room. They are used in conjunction with an airlock system. You may ensure that your cleanroom stays clean and that your product isn't polluted by installing an interlock.

- You understand how crucial it is to keep pollutants out if you are in charge of keeping a cleanroom in working order. Installing interlocks on cleanroom doors is one method to do this.

- These cleanrooms require a spotless environment to prevent contamination by dust particles, bacteria, or other contaminants. Door interlock systems must be installed on all access points to ensure a clean working environment.

- In a cleanroom setting, a door is not simply a door. Understanding how doors, interlocks, and airflow interact is crucial for preserving the integrity of the controlled environment.

- A door is the first line of protection against external pollutants in a cleanroom. It's crucial to have doors that seal well and are constructed of simple materials to clean and disinfect.

How do cleanroom doors do interlocks work?

The interlock door system is an electronic safety feature in many clean rooms. It ensures that personnel cannot enter or exit the room without first opening the door from the inside. An interlocking system is essentially two electrically linked doors so that one door cannot open until the other has closed. You enter the first door with identification, which must close behind you before the second door opens and lets you in.

Cleanroom doors interlocks parts:

A cleanroom door interlock system consists of two parts:

- The door seal:

The door seal is a device that prevents contaminants from entering the clean room when the door is open.

- The door interlock:

Door interlocks are devices installed inside the door frame to ensure that the door cannot be opened unless the door has been properly sealed.

Interlocking systems prevent the door's opening if the door seal is not closed correctly or if there is an obstruction in the doorway. To install a door interlock system, the door must first be equipped with a door seal.

Applications of cleanroom doors interlocks in various fields:

- These doors keep impurities inside the cleanroom from leaving and keep them from entering from the outside. Many businesses employ cleanrooms, such as food processing, medicines, and semiconductor production. Integral circuits and other sensitive electronic components are produced in the semiconductor industry, for instance, in cleanrooms.

- The electronics might potentially be harmed by any impurities that enter the cleanroom. That is why having doors with interlocks is crucial.

- These doors are used in pharmaceuticals, biotechnology, aerospace, food processing, medical equipment, and many other industries.

- These Cleanroom door interlocks are designed to prevent accidental opening of doors during cleaning operations. Many manufacturers have adopted the application of door interlocks as an effective way to ensure safety in clean rooms.

How do maintain cleanroom door interlocks?

These doors are essential to maintaining a clean environment and keeping workers safe. These doors require maintenance to ensure their proper function. There are following steps that must follow to keep the maintenance of these door interlocks.

- Regular cleaning

- Checking for damage

- Make sure they are working properly

What are the benefits of cleanroom door interlocks?

Cleanroom Door Interlock System (CDIS) helps ensure that the door is shut and locked when the operator leaves the room. It ensures that no one opens the door without authorization. CDIS prevents unauthorized access to the cleanroom by preventing the door from being opened if an individual has no authorized access. There are many advantages, but some important are as follows in given below:

- Protects from contamination:

A cleanroom doors interlocks have several advantages, including limiting contamination and lowering the possibility of accidents. A door interlock can also increase a cleanroom's effectiveness by preventing unauthorized door openings.

- Keep environment sterile:

To stop the transmission of illness, it is essential to keep the environment sterile. Ensuring that cleanroom doors and interlocks are installed is one method. This will make it easier to guarantee that no pollutants are carried into the cleanroom and that only authorized employees may enter.

- Saves energy:

This door interlock system has been developed to reduce the time spent opening and closing doors in cleanrooms. These interlocks can be used on any type of door, including cleanroom doors. This innovative product reduces energy costs while improving productivity.

- Improved air quality:

These door interlocks are essential for maintaining high-quality air flow in clean rooms. They prevent contaminated air from entering the clean room. A new technology that has been developed enables easy access to a clean room environment without compromising its air quality.

Conclusion:

Cleanroom Doors Interlocks prevent contamination by blocking airflow through open doorways. They are available on our website, and their configurations meet your needs. With our Door Interlocking System, you can prevent contamination from entering or leaving your facility. EZONG has been providing quality door interlocks for many years. Our unique sealing system improved air quality by reducing contaminants from entering the clean room environment. They have been installed at various institutions and facilities across the globe. It is also an excellent solution for reducing cleaning costs. With its unique design, this product makes cleaning more accessible and safer. Check out our website for more information on this product and buy them.

-

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment

-

Top Aluminium Profile Manufacturers in China: Leading the Global Market

-

The Evolution of Air Tight Sliding Doors

-

AHU Aluminium Profile: A Comprehensive Guide

-

The Importance of Choosing the Right Cleanroom Door in Vietnam

-

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety

-

The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities!

-

Unlock the Possibilities with AJ Manufacturing Doors

-

Make a Statement with Manufactured Home Interior Doors!

-

what is aluminum profile? Aluminum Profiles for Your Home is the best option

-

High Speed Clean Room Doors Cut Contamination Risk

-

Dustproof Cleanroom Door Innovation for Sterile Spaces

-

How Cleanroom Half Glass Swing Door Enhances Sterile Access

-

Why Custom Cleanroom Aluminum Profile Matters Today

-

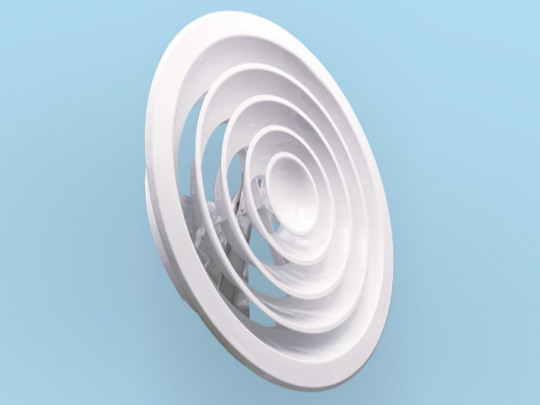

Smart Ceiling Air Diffuser: Dampers Add Full Control

-

E-ZONG: Trusted Air Tight Sliding Cleanroom Door Manufacturer

-

Top Benefits of Clean Room Roll Up Door Systems

-

Cleanroom Glass Door Innovations You Should Know

-

Improve Airflow With the Right Air Diffuser Vent

-

Why Every Laboratory Needs a Sealed Cleanroom Door

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.

.jpg)

Speak Your Mind