Cleanroom Aluminum Profile Installation Guide

- By:Lisa

- 2025-08-14

- 29

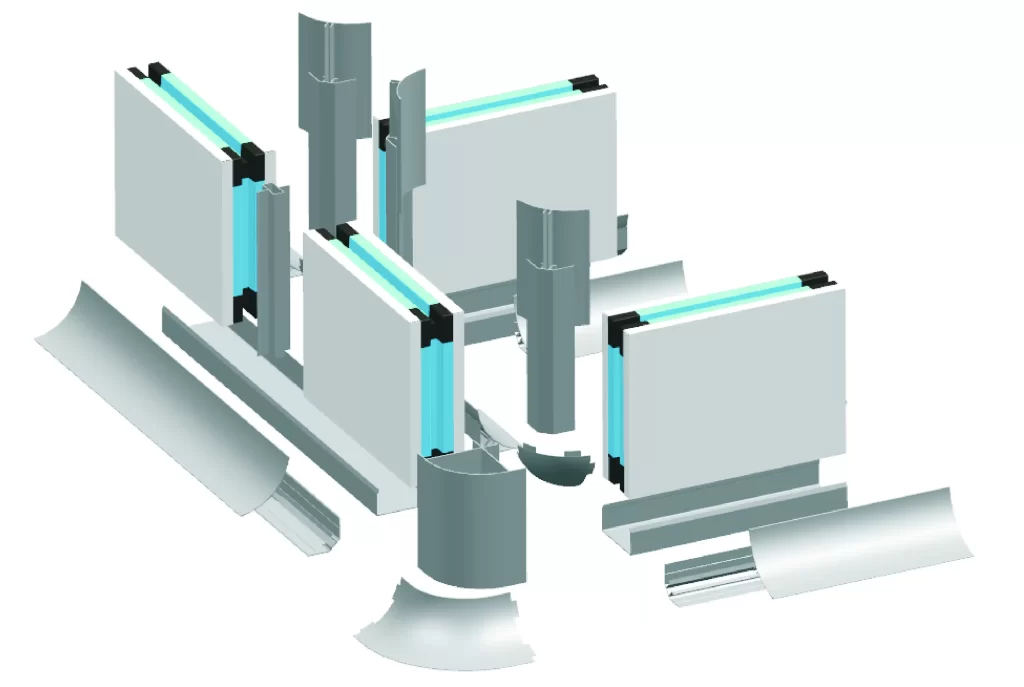

Creating controlled environments for industries like pharmaceuticals, electronics, and biotechnology demands precision to meet ISO 14644-1 air purity standards. Aluminum profiles provide robust structural support and airtight connections, minimizing contamination risks. However, minor installation errors can compromise sealing, affecting product quality. Designed for cleanroom technicians, facility managers, and DIY enthusiasts, this guide offers clear steps to build a compliant cleanroom environment.

Setting up a cleanroom framework requires meticulous attention, akin to assembling a high-tech instrument. For instance, T-slot profiles suit flexible, adjustable setups, whereas modular profiles are ideal for durable, long-term structures. With proper tools and preparation, the process becomes streamlined. Therefore, this guide covers material selection, installation, and maintenance to help you avoid pitfalls and ensure optimal cleanroom performance.

Before starting, thoroughly assess project needs and site conditions. Cleanrooms require strict control of temperature, humidity, and surface flatness, which impact profile alignment. Consequently, preparation involves selecting suitable profiles and gathering tools like laser levels and power drills for efficient, precise setup.

Tools and Materials Needed

To achieve a high-quality profile installation, the right tools and materials are essential. For example, laser levels, power drills, tape measures, and screwdrivers ensure accurate measurements and secure fastening. Additionally, key materials include aluminum profiles (T-slot or modular, ISO 14644-1 compliant), sealing gaskets, fasteners, and cleanroom-compliant cleaning solutions to maintain airtightness and cleanliness.

Material Requirements

Selecting high-quality cleanroom profiles ensures durability and airtightness. Specifically, anodized aluminum profiles offer corrosion resistance and easy cleaning, aligning with GMP (Good Manufacturing Practice) standards. Moreover, silicone or EPDM sealing gaskets provide long-term sealing, while stainless steel bolts prevent rust. Finally, cleanroom-compliant cleaning solutions avoid air contamination.

Tools and Materials Checklist

- Tools:

- Laser Level: Guarantees precise alignment of profiles.

- Power Drill: Secures profiles and panels efficiently.

- Tape Measure: Delivers accurate space measurements.

- Screwdriver (Electric or Manual): Tightens bolts securely.

- Fine-Tooth Cutting Saw: Cuts profiles to exact lengths.

- Materials:

- Aluminum Profiles: T-slot or modular with anodized finish.

- Sealing Gaskets: Silicone or EPDM, resistant to aging.

- Fasteners: Stainless steel bolts and nuts for durability.

- Cleaner: Cleanroom-compliant, VOC-free solutions.

Purchasing Tips

When sourcing materials, verify ISO or GMP certifications to ensure compliance. Additionally, confirm the load-bearing capacity of profiles and check connection compatibility to avoid rework. For best results, request detailed technical specifications from suppliers to select reliable, high-quality materials.

Pre-Installation Preparation

Site Assessment

A comprehensive site assessment lays the foundation for successful installation. Begin by measuring cleanroom dimensions with a tape measure and laser level for millimeter precision, noting wall, floor, and ceiling data. Next, ensure temperature and humidity align with ISO 14644-1 standards. Furthermore, verify that floor flatness deviation is under 2 mm/meter to prevent profile misalignment.

Profile Selection

Understanding how to select cleanroom aluminum profiles is critical for compliance and performance. For instance, T-slot profiles suit temporary or adjustable setups, while modular profiles are ideal for permanent structures. Always choose anodized profiles meeting GMP or ISO standards. Moreover, confirm supplier specifications for load capacity and connection methods to prevent mismatches.

Surface Preparation

To ensure a tight fit, clean walls, floors, and ceilings with cleanroom-compliant cleaning solutions and microfiber cloths to remove dust, oil, or particles. A clean surface is vital for airtightness. Additionally, double-check surface conditions to avoid issues that could impair profile installation.

Safety Precautions

Prioritize safety by wearing personal protective equipment (PPE), including safety glasses, non-slip gloves, and dust masks, to prevent particle inhalation or injury. Furthermore, set up warning signs to restrict unauthorized access to the work area, ensuring a secure environment.

- Site Assessment:

- Measure dimensions to millimeter accuracy.

- Confirm temperature and humidity meet cleanroom standards.

- Ensure floor flatness deviation is under 2 mm/meter.

- Safety Gear:

- Safety Glasses: Shield eyes from debris.

- Non-Slip Gloves: Improve handling safety.

- Dust Mask: Prevent inhalation of particles.

Step-by-Step Installation Process

Step 1: Measure and Mark

Begin by measuring walls, floors, and ceilings with a tape measure and laser level for millimeter accuracy. Next, mark installation points using residue-free markers to ensure precise profile alignment. Errors exceeding 2 mm can disrupt assembly and compromise airtightness.

Step 2: Cut Aluminum Profiles

Using a fine-tooth miter saw, cut profiles to the required lengths. Then, smooth edges with sandpaper or a deburring tool to ensure clean cuts. Smooth edges enhance joint airtightness, reducing contamination risks.

Step 3: Assemble Profile Framework

Connect profiles with compatible brackets and stainless steel fasteners to create tight joints. Additionally, use a square to verify framework squareness, preventing tilts. Gaps at joints can jeopardize compliance with cleanroom standards.

Step 4: Secure Profiles

Fasten profiles to walls, floors, or ceilings using expansion bolts. Before fastening, apply silicone sealant to prevent air leaks. Moreover, use a level to confirm alignment, ensuring a straight, stable structure.

Step 5: Install Panels and Accessories

Attach HPL (high-pressure laminate) or glass panels using silicone gaskets and sealing strips. Next, install doors, windows, or pass-throughs, ensuring tight fits. Finally, check connections for airtightness to prevent particle infiltration.

Step 6: Final Adjustments and Inspection

Tighten all fasteners, checking for looseness. Then, inspect joints and surfaces with a magnifying glass for gaps, misalignments, or scratches. Afterward, wipe profiles and panels with cleanroom-compliant cleaning solutions to remove installation debris, ensuring a pristine environment.

By following these steps to avoid cleanroom installation errors, you can achieve a robust, compliant setup.

Common Mistakes to Avoid

- Inaccurate Measurements:

- Neglecting laser levels, leading to alignment errors.

- Failing to verify measurements, causing joint gaps.

- Using unclear markings, increasing misalignment risks.

- Using Incompatible Materials:

- Choosing non-stainless steel fasteners, which may rust and contaminate.

- Selecting sealing gaskets that fail VOC standards, affecting air quality.

- Pairing mismatched profiles and fasteners, resulting in loose connections.

- Neglecting Surface Preparation:

- Leaving surfaces uncleaned, allowing dust or oil to impair fit.

- Ignoring floor flatness, causing unstable profiles.

- Using improper cleaners, leaving volatile residues.

Long-Term Maintenance Tips

To maintain cleanroom profiles effectively, regular cleaning is essential. Specifically, employ cleanroom-compliant cleaning solutions and microfiber cloths to remove dust and particles, avoiding scratches on anodized surfaces. Additionally, clean high-touch areas like door frames or pass-throughs weekly, steering clear of acidic or alkaline cleaners.

Periodically inspect sealing gaskets and fasteners. For example, check silicone or EPDM gaskets monthly, replacing worn components. Moreover, use a torque wrench to test stainless steel fasteners for tightness, ensuring no rust or loosening.

Address damage promptly. For instance, repair scratches or dents with specialized touch-up paint. Similarly, replace damaged sealing gaskets or reapply silicone sealant to fix joint gaps, maintaining airtightness.

- Routine Cleaning:

- Employ cleanroom-compliant cleaning solutions and microfiber cloths.

- Clean high-touch areas weekly.

- Avoid acidic or alkaline cleaners to protect surface coatings.

- Seal and Fastener Checks:

- Inspect sealing gaskets monthly, replacing worn parts.

- Test fastener tightness to ensure stability.

- Verify stainless steel bolts for rust prevention.

- Prompt Damage Repairs:

- Apply touch-up paint for scratches or dents.

- Replace damaged sealing gaskets and reapply sealant.

- Check joints to address minor gaps.

Frequently Asked Questions

Which aluminum profiles are best for cleanrooms?

Aluminum profiles provide critical support and sealing for cleanrooms. Specifically, 6063-T5 aluminum alloy is preferred for its strength and corrosion resistance, often anodized for smoothness and reduced dust adhesion. For ISO 5 cleanrooms (Class 100), select profiles with a 2 mm or thicker wall for stability. Additionally, modular designs simplify assembly and maintenance. Consult suppliers for tailored profile selection based on your industry, such as pharmaceuticals or electronics.

How do I ensure airtight sealing during installation?

Airtightness is crucial to prevent dust ingress. Therefore, use high-quality silicone sealing gaskets (heat- and aging-resistant) to fill profile joints. Ensure cut surfaces are smooth, with errors under ±0.5 mm, to avoid gaps. Furthermore, specialized connectors like angle brackets or T-bolts enhance joint stability, paired with sealant strips for added protection. After installation, use a differential pressure tester to verify the cleanroom’s positive pressure meets design requirements.

Can cleanroom profile installation be done without professionals?

DIY cleanroom profile installation is feasible but requires skill and precision. Cleanrooms demand accuracy, and errors can compromise performance. Consider the following:

- Tools: Employ a laser level, power cutter, and torque wrench for accuracy.

- Skills: Understand profile assembly and cleanroom airflow/sealing standards.

- Time: Non-professionals may face longer timelines and higher error risks.

Hiring professionals saves time, as they possess specialized tools and extensive experience to address on-site issues efficiently. For smaller projects or budget constraints, DIY is possible, but study specifications thoroughly and consult experts on critical steps like sealing. For example, EZONG’s cleanroom aluminum extrusions are a reliable choice, ensuring high-quality installation that meets standards and improves efficiency.

-

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment -

Top Aluminium Profile Manufacturers in China: Leading the Global Market

Top Aluminium Profile Manufacturers in China: Leading the Global Market -

The Evolution of Air Tight Sliding Doors

The Evolution of Air Tight Sliding Doors -

AHU Aluminium Profile: A Comprehensive Guide

AHU Aluminium Profile: A Comprehensive Guide -

The Importance of Choosing the Right Cleanroom Door in Vietnam

The Importance of Choosing the Right Cleanroom Door in Vietnam -

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety -

.jpg) The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities!

The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities! -

Unlock the Possibilities with AJ Manufacturing Doors

Unlock the Possibilities with AJ Manufacturing Doors -

Make a Statement with Manufactured Home Interior Doors!

Make a Statement with Manufactured Home Interior Doors! -

what is aluminum profile? Aluminum Profiles for Your Home is the best option

what is aluminum profile? Aluminum Profiles for Your Home is the best option

-

How to Extend the Life of Your Exterior Steel Door

How to Extend the Life of Your Exterior Steel Door -

What Are the Best Materials for AC Vent Covers

What Are the Best Materials for AC Vent Covers -

Ceiling Vent Covers Labeled Fire-Rated? Here’s How to Verify

Ceiling Vent Covers Labeled Fire-Rated? Here’s How to Verify -

Upgrading Lab Doors: When to Replace vs. When to Retrofit?

Upgrading Lab Doors: When to Replace vs. When to Retrofit? -

Stainless Steel Door vs. Alternatives in Cleanrooms

Stainless Steel Door vs. Alternatives in Cleanrooms -

Ceiling Vent Care Tips to Boost HVAC Efficiency Year Round

Ceiling Vent Care Tips to Boost HVAC Efficiency Year Round -

How Air Dampers Drive Efficiency in High Performance Buildings

How Air Dampers Drive Efficiency in High Performance Buildings -

Why Semiconductor Manufacturing Can’t Function Without Cleanrooms

Why Semiconductor Manufacturing Can’t Function Without Cleanrooms -

How to Select the Right Floor Vent for Cleanrooms

How to Select the Right Floor Vent for Cleanrooms -

How to Clean and Maintain AC Registers for Peak HVAC Performance

How to Clean and Maintain AC Registers for Peak HVAC Performance

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.

Speak Your Mind