Clean Room Doors Manufacturer - Industry Leader in Door Management with 3 Finishes, 5 Locking Options,

- By:hqt

- 2022-10-21

- 29

Clean room doors are an essential part of a clean room, laboratory, or another controlled environment. Clean rooms require that everything has to be kept inside and outside the room is strictly monitored for contamination. A clean room door is a perfect solution to control the entry and exit into these spaces. Our clean room doors manufacturer offers you excellent quality doors with advanced features at affordable prices. Clean rooms are designed to have limited air exchange in order to keep contamination levels as low as possible. This means that it needs special door management systems that can operate in controlled environments while preventing the uncontrolled exchange of air between areas with different operating conditions - such as clean rooms and non-clean areas like corridors or vestibules.

5 types of cleanroom doors

A clean room door is a physical barrier that prevents the entry of contaminants into or out of a clean room. A clean room door can be a manually operated swinging door, a sliding door, a pressure differential door, or an air curtain. These doors can be applied individually or as part of a clean room system. There are 5 different types of Cleanroom Door available on the market: - Manual Swinging Clean Room Door: This is the most common type of clean room door. It is easy to operate and maintain. The only downside is the noise it creates when operated manually. - Manual Sliding Clean Room Door: This door is similar to the swinging door, but it slides up and down. Although it only comes with a single-leaf design, it is often used as an emergency exit door. - Automated Swinging Clean Room Door: This is a door that automatically opens and closes. The advantage of this type of door is that it is almost silent. It is also energy efficient and has a low cost of ownership. - Automated Sliding Clean Room Door: This type of door is designed to slide horizontally. It is similar to a bi-fold door and is available in single- or double-leaf designs. - Hydraulic Clean Room Door: This type of door is similar to a hydraulic pressure differential door. It is generally used as an emergency door in laboratories or as a decontamination door.

5 different types of locking mechanisms

There are 5 different types of locking mechanisms for clean room doors - each with its own advantages. The locking mechanism is the part of the door that is used to control the entry and exit into the space. It can be used either manually or automatically. The most common locking mechanisms for clean rooms are: - Standard Positive Locking: This is the most common locking mechanism and can be found on most clean room doors. It is easy to install manually or automatically. It is reliable and safe, but it does not seal the door completely. - Standard Negative Locking: This locking mechanism is similar to the positive locking mechanism. The only difference is that it uses a spring-loaded mechanism to automatically close and seal the door. - Electrical Locking: This locking mechanism uses an electric solenoid to control the door. It is usually installed on clean room doors and decontamination doors, where an automatic door closer is required. - Hydraulic Locking: This locking mechanism uses hydraulic pressure to control the door. It is usually installed on clean rooms that require decontamination or emergency exit as it is designed to open a large door quickly. - Air Locking: This is a locking mechanism that uses air to close and seal the clean room door. It is commonly found on clean rooms with air curtains.

3 finishes available for clean room doors

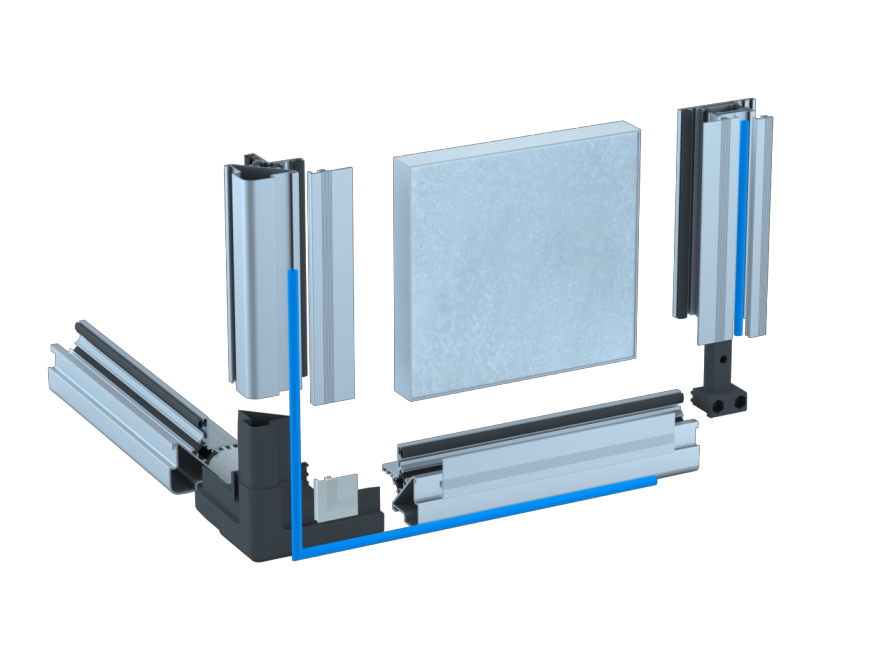

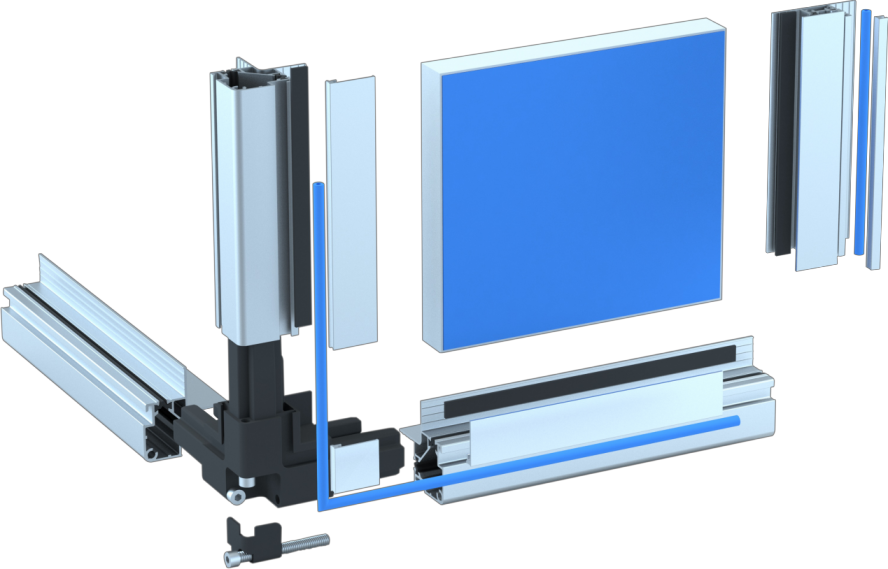

The finish of a clean room door can significantly impact its aesthetics, performance, and cost. There are 3 finishes available for clean room doors - stainless steel, galvanized steel, and aluminium. A stainless steel finish is a popular choice as it is durable and easy to clean. It is, however, the most expensive option. A galvanized steel finish is cheaper than stainless steel, but it is not as durable and prone to rust. A galvanized steel finish is perfect for clean rooms to prevent rust and corrosion. However, it is not ideal for clean rooms that require a high level of hygiene as it is difficult to clean. An aluminium finish is less expensive than stainless steel and is more durable. It is also easy to clean, but it is not as durable as stainless steel.

2 types of seals available for clean rooms

The seal of a clean room door can be either a static seal or a dynamic seal. A static seal is the standard seal type used in clean rooms. A static seal is closed and does not allow air to flow through it. A dynamic seal, on the other hand, allows air to flow through it. A dynamic seal is used in places where a static seal would not be suitable, such as in laboratories or clean rooms that require air to flow through it.

1. Solid Doors

This is the most commonly used clean room door. It is made of a single sheet of metal and is usually made of stainless steel or aluminium. It is designed to be airtight and can be installed manually or automatically. The only disadvantage is that it cannot be used as an emergency exit door.

2. Sliding Doors with Double-Sided Seal

This clean room door is similar to a sliding door with a double-sided seal. It is an automatic door that slides vertically and is used in clean rooms. It is also suitable for laboratories where it is required that air should be allowed to flow in and out of the clean room.

3. Sliding Doors with Single-Sided Seal

This is a clean room door that slides vertically and uses a single-sided seal. It is suitable for laboratories where air needs to be allowed to flow in and out of the clean room. It is not suitable for clean rooms where the door must be airtight.

4. Double Sliding Doors with Double-Sided Seal

This clean room door is used in clean rooms and laboratories where air needs to flow in and out of the room. It is made of two sliding doors with double-sided seals. It is an automatic door that slides vertically.

5. Double Sliding Doors with Single-Sided Seal

This clean room door is similar to a double sliding door with a single-sided seal. It is an automatic door that slides vertically. It is suitable for laboratories where air needs to flow in and out of the clean room. These are just a few benefits that come with clean room doors. There are many more benefits, such as the fact that clean room doors are durable and come in many different styles and finishes, like stainless steel or aluminum. They are also easy to clean and come with many different types of seals, such as static seals and dynamic seals. Now that you know all about clean room doors, it’s time to make your selection! With so many different types available, it’s important to do your research and find the one that best suits your unique needs. And don’t forget to consider the finishing of the door, as this will have an impact on the overall aesthetics of your space.

-

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment -

Top Aluminium Profile Manufacturers in China: Leading the Global Market

Top Aluminium Profile Manufacturers in China: Leading the Global Market -

The Evolution of Air Tight Sliding Doors

The Evolution of Air Tight Sliding Doors -

AHU Aluminium Profile: A Comprehensive Guide

AHU Aluminium Profile: A Comprehensive Guide -

The Importance of Choosing the Right Cleanroom Door in Vietnam

The Importance of Choosing the Right Cleanroom Door in Vietnam -

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety -

.jpg) The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities!

The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities! -

Unlock the Possibilities with AJ Manufacturing Doors

Unlock the Possibilities with AJ Manufacturing Doors -

Make a Statement with Manufactured Home Interior Doors!

Make a Statement with Manufactured Home Interior Doors! -

what is aluminum profile? Aluminum Profiles for Your Home is the best option

what is aluminum profile? Aluminum Profiles for Your Home is the best option

-

Guide to Doors Clean Room: Ensuring Contamination Control

Guide to Doors Clean Room: Ensuring Contamination Control -

Introducing Guangdong Clean Room Aluminum Company: E-ZONG

Introducing Guangdong Clean Room Aluminum Company: E-ZONG -

Cost-Effectiveness of Bulk Purchasing Air Diffuser

Cost-Effectiveness of Bulk Purchasing Air Diffuser -

Makeup Air Handling Unit: Here to Know

Makeup Air Handling Unit: Here to Know -

Customizing HVAC Systems Parts for Building Specific Needs

Customizing HVAC Systems Parts for Building Specific Needs -

How Return Air Diffuser Enhances HVAC Efficiency for Your Projects

How Return Air Diffuser Enhances HVAC Efficiency for Your Projects -

Exploring the Versatility of Swing Glass Door

Exploring the Versatility of Swing Glass Door -

Choosing Quality: Why Linear Diffuser Grille is Essential in Modern Design

Choosing Quality: Why Linear Diffuser Grille is Essential in Modern Design -

Introduction to Clean Room High Speed Doors: Let’s Dive into

Introduction to Clean Room High Speed Doors: Let’s Dive into -

High-Quality Clean Room Double Door for Medical and Health

High-Quality Clean Room Double Door for Medical and Health

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.

Speak Your Mind