Precision Performance: Clean Room Aluminum Profiles

- By:hqt

- 2023-12-12

- 29

Clean room aluminum profiles serve as fundamental building blocks for creating controlled environments where cleanliness, precision, and sterility are paramount. These profiles play a vital role in constructing structures and fixtures within clean rooms, ensuring the maintenance of rigorous standards for cleanliness and contamination control. Clean room environments are essential across various industries, such as pharmaceuticals, electronics manufacturing, biotechnology, and research and development. The importance of clean rooms cannot be overstated, as they directly impact product quality, safety, and compliance with regulatory requirements. Contaminants, whether in the form of particles, microorganisms, or chemicals, can compromise the integrity of processes and products.

Applications of Clean Room Aluminum Profiles:

Hospital Construction

Clean room aluminum profiles are ideal for constructing specialized areas within hospitals, such as operating rooms, isolation units, and sterile supply rooms. These profiles facilitate the creation of airtight and sterile environments necessary for surgical procedures, infection control, and patient safety.

Biomedical Laboratories

Biomedical laboratories demand stringent cleanliness and contamination control. Clean room aluminum profiles are used to construct laboratory spaces for research, diagnostics, and testing. These profiles ensure controlled environments for the handling of sensitive samples and experiments in fields like microbiology and genetics.

Food Processing Plants

Cleanliness and airtightness are paramount in food processing to maintain product safety and quality. Clean room aluminum profiles find application in constructing controlled environments for food manufacturing, packaging, and storage. These profiles prevent contamination, regulate temperature, and facilitate compliance with food safety standards.

Other High-Cleanliness Environments

Clean room aluminum profiles are versatile and adaptable, making them suitable for various applications beyond hospitals, laboratories, and food processing plants. They are used in industries such as semiconductor manufacturing, aerospace, and pharmaceuticals, where precision, sterility, and contamination control are critical.

Benefits of Clean Room Aluminum Profiles:

Cleanliness and Sterility

Contamination Control: Clean room aluminum profiles enable the creation of environments with controlled cleanliness levels, minimizing the presence of particles, microorganisms, and pollutants.

Sterile Environments: These profiles contribute to the maintenance of sterile conditions necessary for critical processes in pharmaceuticals, biotechnology, and healthcare settings.

Improved Product Quality: By preventing contamination, clean room profiles help ensure the production of high-quality products, particularly in industries like electronics manufacturing and food processing.

Durability and Corrosion Resistance

Longevity: Clean room aluminum profiles are known for their durability and resistance to wear and tear, ensuring a long service life.

Corrosion Resistance: Aluminum profiles are inherently resistant to corrosion, making them suitable for environments with stringent cleanliness requirements and high humidity levels.

Customization Options

Design Flexibility: Clean room aluminum profiles offer design versatility, allowing for the creation of tailored clean room layouts, partitions, and enclosures to meet specific operational needs.

Compatibility: These profiles can be customized to accommodate various accessories, such as doors, windows, and air handling systems, enhancing their adaptability.

Ease of Installation

Efficient Assembly: Clean room aluminum profiles are designed for easy and efficient installation, reducing construction time and costs.

Minimal Disruption: Quick installation minimizes disruptions to ongoing operations, making them suitable for retrofitting existing spaces into clean room environments.

Compliance with Industry Standards

Regulatory Compliance: Clean room aluminum profiles are engineered to meet stringent industry standards and regulations, ensuring adherence to cleanliness and contamination control guidelines.

Documentation and Certification: Manufacturers often provide documentation and certifications to verify compliance with specific clean room requirements, offering peace of mind to users.

Key Attributes of Cleanroom Aluminum Profiles

Material Specifications

Cleanroom aluminum profiles typically utilize high-quality, corrosion-resistant aluminum alloys such as 6061 or 6063. These materials offer exceptional strength and durability, all while maintaining a lightweight composition, making them an optimal choice for cleanroom applications.

Surface Finishes

Cleanroom aluminum profiles are available in a diverse range of surface finishes tailored to meet specific cleanliness and aesthetic requirements. Among the commonly employed surface finishes is anodized aluminum, which provides superior corrosion resistance and a sleek, easy-to-clean surface. Powder coating is another option, offering both color customization and profile protection.

Profile Designs and Dimensions

Cleanroom aluminum profiles boast extensive diversity in design and dimensions, accommodating various cleanroom layouts and applications. Standard profiles include T-slotted, square, and rectangular shapes, with the flexibility to customize profiles to suit project-specific needs, often featuring slots for convenient accessory attachment.

Jointing Methods

Cleanroom aluminum profiles offer versatile jointing methods for efficient structure assembly. Common jointing techniques encompass mechanical connectors, brackets, and bolts, ensuring stability and adaptability when configuring cleanroom infrastructure.

Sealing Options

Maintaining the integrity of a cleanroom environment hinges on effective sealing. Cleanroom aluminum profiles can be equipped with a variety of sealing options to ward off contaminants. Gaskets, silicone seals, and EPDM seals are frequently employed to seal joints and connections effectively.

Cleanroom aluminum profiles play a key role in the construction of modular cleanroom environments that adhere to strict cleanliness and contamination control standards. By wisely choosing material specifications, surface finishes, profile designs, joining methods and sealing alternatives. You can create original and controlled setups that benefit sensitive processes and applications.

Experience Excellence with Clean Room Aluminum Profiles: Elevate Your Precision Performance Today!

Clean room aluminum profiles are a paragon of precision, offering outstanding quality, adaptability, and dependability. These profiles are made from corrosion-resistant materials and feature customizable designs. And equipped with powerful sealing options, ensuring a sterile and regulated environment that meets strict standards. Whether in critical manufacturing or research areas. Clean room aluminum profiles are an integral element in achieving excellence by delivering the precision required for peak performance.

-

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment

-

Top Aluminium Profile Manufacturers in China: Leading the Global Market

-

The Evolution of Air Tight Sliding Doors

-

AHU Aluminium Profile: A Comprehensive Guide

-

The Importance of Choosing the Right Cleanroom Door in Vietnam

-

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety

-

The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities!

-

Unlock the Possibilities with AJ Manufacturing Doors

-

Make a Statement with Manufactured Home Interior Doors!

-

what is aluminum profile? Aluminum Profiles for Your Home is the best option

-

High Speed Clean Room Doors Cut Contamination Risk

-

Dustproof Cleanroom Door Innovation for Sterile Spaces

-

How Cleanroom Half Glass Swing Door Enhances Sterile Access

-

Why Custom Cleanroom Aluminum Profile Matters Today

-

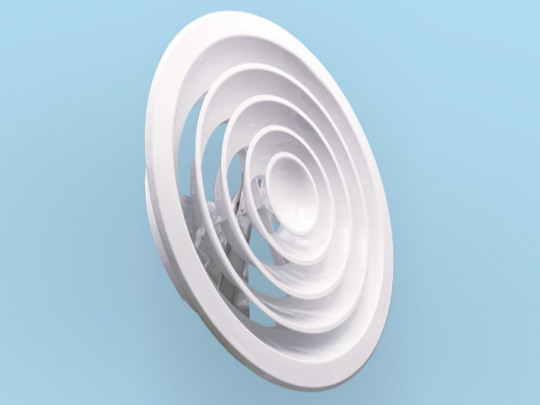

Smart Ceiling Air Diffuser: Dampers Add Full Control

-

E-ZONG: Trusted Air Tight Sliding Cleanroom Door Manufacturer

-

Top Benefits of Clean Room Roll Up Door Systems

-

Cleanroom Glass Door Innovations You Should Know

-

Improve Airflow With the Right Air Diffuser Vent

-

Why Every Laboratory Needs a Sealed Cleanroom Door

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.

.jpg)

Speak Your Mind