Aluminum Vs. Plastic Return Air Grilles for Cleanrooms

- By:Lisa

- 2025-10-11

- 29

You want the cleanest air possible in your facility. Aluminum return air grille options give you top performance for hygiene, durability, and easy cleaning. Material choice matters for air quality and meeting strict regulations. Facility managers often compare aluminum with plastic, but aluminum stands out for practical reasons in demanding environments.

Key Takeaways

- Aluminum return air grilles are non-porous, making them easier to clean and preventing dust and microbes from building up.

- These grilles help maintain strict hygiene standards in sensitive environments like hospitals and laboratories.

- Aluminum grilles resist corrosion and damage, ensuring a longer lifespan compared to plastic alternatives.

- Regular maintenance of aluminum grilles is simple, allowing for quick filter changes and cleaning without special tools.

- Choosing aluminum grilles can save money over time due to their durability and lower replacement needs.

- Aluminum grilles support better air quality by preventing particle shedding and microbial growth.

- Customization options for aluminum grilles allow you to meet specific facility needs and compliance standards.

- Investing in aluminum grilles shows a commitment to safety and quality in clean environments.

Clean Environment Needs

Hygiene Standards

You need to meet strict hygiene standards in clean environments. Facilities like hospitals, laboratories, and cleanrooms require surfaces that do not trap dust or microbes. A return air grille must have a smooth, non-porous surface. This design prevents bacteria and mold from growing. You can easily wipe down these surfaces, which helps you maintain a sanitary space. Regulatory bodies often inspect these areas. They expect you to use materials and equipment that support high cleanliness. Choosing the right grille helps you pass inspections and keep your environment safe.

Contamination Control

Controlling contamination is a top priority in sensitive environments. The return air grille plays a key role in this process. It helps remove airborne particles and keeps the air clean. You need to ensure that airflow patterns move contaminants away from critical areas. The grille directs air toward exhaust points, which helps maintain proper pressure and airflow. This process supports the dilution and removal of contaminants.

| Aspect | Description |

|---|---|

| Dilution and Removal | Facilitates the removal and dilution of airborne contaminants through well-mixed air distribution of filtered air. |

| Airflow Patterns | Directs contaminants toward exhaust registers and grilles via uniform, non-mixed airflow patterns. |

| Pressure Differentials | Maintains proper airflow patterns and pressure differentials essential for contamination control. |

| Building Pressurization | Ensures pressurization of individual spaces relative to others and the building relative to the outdoors. |

You should also keep doors closed and make sure inlet filters and air return vents stay clean. These steps help you maintain a controlled environment and reduce the risk of contamination.

Maintenance Ease

Easy maintenance is essential for any clean environment. You need to check and replace filters in your return air grille regularly. This practice keeps the airflow strong and prevents the system from clogging. Clean filters also help your HVAC system run efficiently. When you replace prefilters on time, you extend the life of more expensive HEPA filters.

| Maintenance Practice | Description |

|---|---|

| Regularly check and replace prefilters | Ensures cleanroom air flow and HVAC air flow at designed volumes, preventing clogging and inefficiency. |

| Extend HEPA fan filter life | Regular replacement of prefilters on return air grills helps prolong the life of HEPA filters. |

- Remove and clean air filters from return air grilles to maintain optimal airflow and system efficiency.

- Replace air filters every 1–3 months to ensure good indoor air quality.

By following these steps, you make sure your facility stays compliant with hygiene standards and operates efficiently.

Air Quality

Air quality stands as a top priority in any clean environment. You need to control airborne particles, dust, and microbes to protect sensitive processes and people. The return air grille plays a direct role in this effort. When you select the right grille, you help your HVAC system filter and circulate clean air throughout your facility.

Aluminum return air grilles offer a clear advantage for air quality. Their non-porous surfaces do not trap dust or bacteria. You can clean these grilles quickly, which prevents buildup and keeps contaminants out of the air. In cleanrooms, laboratories, and hospitals, you must meet strict air quality standards. Regulatory agencies often require you to use materials that do not shed particles or support microbial growth. Aluminum meets these requirements and helps you maintain compliance.

Tip: Regularly inspect and clean your return air grilles. This simple step improves air quality and extends the life of your HVAC filters.

You also need to consider airflow patterns. The design of a return air grille affects how air moves through your space. Louvered aluminum grilles direct air efficiently, reducing turbulence and preventing dead zones where contaminants can settle. Consistent airflow supports even filtration and helps you maintain positive or negative pressure as needed for your application.

Here is a quick comparison of how grille material impacts air quality:

| Feature | Aluminum Return Air Grille | Plastic Return Air Grille |

|---|---|---|

| Particle Shedding | Minimal | Possible |

| Microbial Resistance | High | Moderate |

| Cleaning Frequency | Low | High |

| Regulatory Compliance | Excellent | Variable |

You want to avoid materials that degrade or release particles over time. Plastic grilles can crack or warp, leading to gaps that let unfiltered air bypass the system. Aluminum resists these issues, providing a tight seal and consistent performance.

In cleanroom applications, every detail matters. You must choose equipment that supports your air quality goals. An aluminum return air grille gives you confidence that your facility meets both internal standards and external regulations. By investing in quality materials, you protect your processes, your products, and the people who rely on your clean environment.

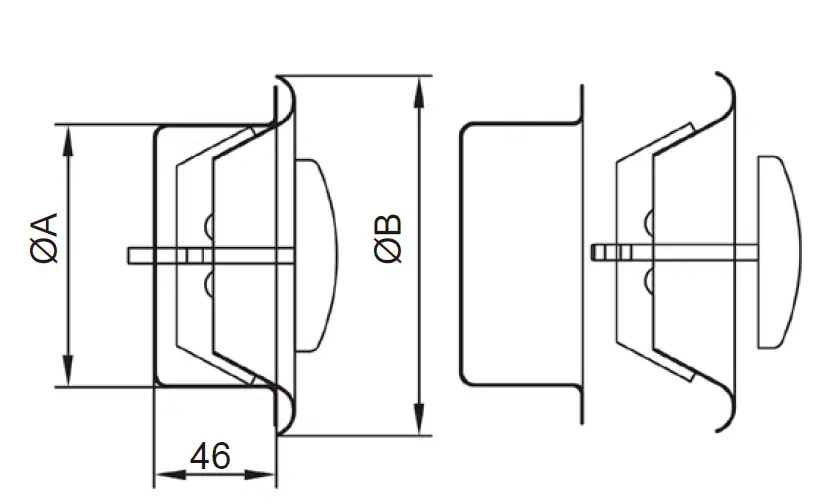

return air grille Features

Louvered Design

You want efficient airflow in your facility. The louvered design of a return air grille plays a key role in this. Angled slats guide air in a specific direction, which helps you control the movement of air throughout your space. This design reduces resistance, so your HVAC system does not have to work as hard. You get better ventilation and more consistent temperatures.

- Directional control: The angled slats let you direct airflow where you need it.

- Reduced resistance: Louvered designs allow air to pass through with less effort, improving system efficiency.

- Prevention of drafts: You can minimize drafts and avoid hot or cold spots.

- Improved ventilation: The design supports better air circulation, which is vital for clean environments.

You benefit from a louvered aluminum grille because it keeps airflow steady and predictable. This helps you maintain the right pressure and air quality in sensitive areas.

Removable Face

Cleaning and maintenance become much easier when you choose a return air grille with a removable face. You can quickly access the inside of the grille without special tools. This feature saves you time during routine cleaning or filter changes. In clean environments, you need to remove dust and debris often. A removable face lets you do this without disturbing other parts of your HVAC system.

You also reduce downtime. Staff can open the grille, clean it, and close it again in just a few minutes. This keeps your facility running smoothly and helps you meet hygiene standards. Many aluminum grilles offer this feature, making them a smart choice for places where cleanliness matters most.

Tip: Choose a grille with a hinged or removable face for faster maintenance and better compliance with cleaning protocols.

Filter Compatibility

You need your return air grille to work with standard filter sizes. This ensures you can replace filters easily and keep your system running at peak performance. Many grilles support a range of filter types, including prefilters and HEPA filters. This flexibility lets you adapt your system to changing needs or stricter regulations.

Some grilles also offer advanced customization options to meet specific facility requirements:

| Customization Option | Description |

|---|---|

| 316 Stainless Steel Construction | Provides corrosion resistance, ideal for facilities dealing with corrosive substances. |

| Antimicrobial Epoxy Powder Coat Finish | Offers infection prevention by protecting grilles from harmful particles. |

| Opposed Damper Blades | Allows for targeted airflow control, enhancing air distribution efficiency. |

| Variety of Inlet Options | Ensures compatibility with different HVAC system designs and requirements. |

| Hinged Air Grilles | Facilitates easy access for maintenance and filter changes, improving overall system efficiency. |

You can select the right combination of features for your application. This helps you maintain air quality, meet compliance standards, and simplify maintenance. When you choose a return air grille with these features, you invest in the long-term health and efficiency of your facility.

Customization

You want your return air grille to fit your facility’s unique needs. Customization gives you control over the design, material, and features of your grille. You can choose options that improve performance, meet regulatory standards, and match your cleanroom applications.

Aluminum return air grilles offer the widest range of customization. You can select different sizes, shapes, and finishes. You can request powder-coated surfaces for extra protection or antimicrobial coatings for infection control. You can also specify the thickness of the aluminum to increase durability. These choices help you create a grille that works perfectly in your environment.

You can also choose from other materials, such as stainless steel, wood, or resin. Stainless steel provides excellent corrosion resistance. Wood offers a decorative look but does not suit cleanroom applications. Resin grilles work in less demanding settings but lack the strength and hygiene of aluminum.

| Material Option | Best Use Case | Benefits | Limitations |

|---|---|---|---|

| Aluminum | Cleanrooms, labs, hospitals | Non-porous, durable, customizable | Higher initial cost |

| Stainless Steel | Corrosive environments | Corrosion-resistant, strong | Heavier, more expensive |

| Wood | Offices, homes | Decorative, lightweight | Not suitable for cleanrooms |

| Resin/Plastic | Light-duty areas | Affordable, easy to mold | Porous, less durable |

You can customize the grille’s louver pattern to control airflow. You can select opposed blade dampers for precise air distribution. You can add hinged faces for easy filter changes. You can request compatibility with specific filter sizes, including HEPA or ULPA filters for cleanroom applications.

Tip: Ask your supplier about custom laser-cut logos or identification tags. These features help you track maintenance and ensure compliance with facility standards.

You can also match the grille’s color to your facility’s design. You can choose white, silver, or custom colors to blend with walls or ceilings. You can select flush-mount or surface-mount styles for different installation needs.

You benefit from working with a supplier who understands cleanroom requirements. You get expert advice on selecting the right aluminum return air grille for your application. You can ask for documentation to support regulatory compliance. You can request samples to test fit and finish before placing a large order.

You improve air quality, hygiene, and efficiency when you invest in a customized return air grille. You protect your processes and meet the strict standards of clean environments. You show your commitment to safety and quality by choosing the best grille for your facility.

Aluminum Grille Benefits

Image Source: unsplash

Non-Porous Surface

You want surfaces that do not trap contaminants in your clean environment. Aluminum grilles provide a non-porous surface, which means bacteria and dust cannot penetrate or hide in tiny crevices. This feature makes cleaning much easier and more effective. When you wipe down an aluminum return air grille, you remove almost all particles and microbes. You do not need harsh chemicals or repeated scrubbing.

Aluminum surfaces also show hydrophobic properties. Water and other liquids do not stick easily, so you see less bacterial attachment compared to plastic grilles. The material even helps inactivate microbes, which boosts hygiene and lowers contamination risks.

- Aluminum surfaces resist bacterial growth.

- You clean aluminum grilles faster and more thoroughly.

- Microbial inactivation potential adds another layer of protection.

If you manage a hospital, laboratory, or cleanroom, you know that every surface matters. Choosing a non-porous aluminum grille helps you meet strict hygiene standards and keeps your air clean.

Corrosion Resistance

You need equipment that stands up to tough conditions. Aluminum grilles offer excellent corrosion resistance, which means they last longer and perform better in demanding environments. In HVAC systems, corrosion can cause major problems. Copper tubing often fails because of formicary corrosion—a reaction between oxygen, water, and organic acids. Aluminum does not suffer from this issue. You get a grille that stays strong and reliable, even when exposed to moisture or cleaning agents.

Aluminum’s immunity to formicary corrosion saves you money. You avoid premature failures and reduce costs for repairs and replacements. You also lower warranty claims, which helps your facility run smoothly. When you choose aluminum, you invest in durability and long-term value.

Easy Sanitization

You want to sanitize your equipment quickly and efficiently. Aluminum grilles make this process simple. The smooth, non-porous surface allows you to wipe away dust, dirt, and microbes with minimal effort. You do not need special tools or chemicals. Regular cleaning keeps your return air grille in top condition and supports your facility’s hygiene goals.

Tip: Use a soft cloth and mild disinfectant for routine cleaning. You maintain a safe environment and extend the life of your grille.

Aluminum grilles also resist staining and discoloration. You keep your facility looking professional and compliant with industry standards. In cleanrooms and healthcare settings, easy sanitization helps you meet regulatory requirements and protect sensitive processes.

If you want a grille that supports your cleaning protocols, aluminum stands out as the best choice. You save time, reduce labor costs, and improve overall safety.

Durability

You need equipment that stands the test of time in your cleanroom or controlled environment. Durability is a key reason why aluminum return air grilles outperform plastic alternatives. When you choose an aluminum return air grille, you invest in a product that resists wear, impact, and environmental stress. This strength ensures your ventilation system remains reliable, even in demanding applications like laboratories, hospitals, and food processing plants.

Aluminum’s natural properties give it a clear advantage. The metal does not crack, warp, or become brittle under temperature changes. You can expect your aluminum return air grille to maintain its shape and function for many years. This durability means fewer replacements and less downtime for your facility. You save money on maintenance and avoid the hassle of frequent repairs.

Note: In cleanroom applications, even minor damage to a return air grille can compromise air quality and regulatory compliance. Aluminum grilles help you avoid these risks by providing long-lasting protection.

Plastic grilles often fail under stress. They may deform when exposed to heat or cleaning chemicals. Over time, plastic can become discolored or brittle, leading to cracks and gaps. These weaknesses allow contaminants to enter your clean environment, putting your processes and people at risk.

Here are some reasons why aluminum return air grilles deliver superior durability:

- Impact Resistance: Aluminum withstands accidental bumps and knocks without denting or breaking.

- Thermal Stability: The metal handles temperature fluctuations without warping or losing strength.

- Chemical Resistance: Aluminum resists damage from common cleaning agents used in cleanroom maintenance.

- Structural Integrity: The rigid frame keeps its shape, ensuring a tight seal and consistent airflow.

You also benefit from the lightweight nature of aluminum. You can install and handle these grilles easily, reducing labor costs and installation time. Despite being light, aluminum offers impressive strength, making it ideal for both ceiling and wall-mounted return air grille applications.

A durable aluminum return air grille supports your facility’s long-term goals. You maintain high air quality, meet regulatory standards, and reduce total cost of ownership. When you select aluminum, you show your commitment to quality and reliability in every aspect of your cleanroom or controlled environment.

Tip: Ask your supplier about warranty options for aluminum return air grilles. A strong warranty reflects confidence in the product’s durability and gives you peace of mind.

By choosing aluminum, you ensure your clean environment remains protected and efficient for years to come.

Plastic Grille Drawbacks

Porosity

Plastic return air grilles have a porous structure. You may not see these tiny pores, but they exist on the surface and inside the material. These pores trap dust, dirt, and even moisture. When you use plastic grilles in cleanroom applications, you risk allowing contaminants to settle and build up over time. This buildup can affect the performance of your HVAC system and reduce air quality.

A porous surface also makes it harder for you to achieve a thorough clean. Even after you wipe the grille, some particles remain hidden in the pores. In sensitive environments, such as laboratories or hospitals, this can lead to hygiene problems. You want a return air grille that does not hold onto contaminants. Aluminum return air grilles offer a non-porous alternative, making them a better choice for clean environments.

Note: Porosity in plastic grilles can lead to hidden contamination that you cannot remove with regular cleaning.

Microbial Growth

Plastic grilles create an environment where microbes can thrive. The pores in plastic trap moisture, which encourages the growth of bacteria, mold, and fungi. If you manage a cleanroom or healthcare facility, you know that microbial contamination can threaten your processes and safety standards.

You may notice unpleasant odors or visible mold spots on plastic return air grilles. These signs indicate microbial growth, which can spread to other parts of your HVAC system. Once microbes take hold, they become difficult to eliminate. You need to replace the grille or use harsh chemicals, which increases maintenance costs and downtime.

| Risk Factor | Plastic Grille | Aluminum Grille |

|---|---|---|

| Microbial Growth | High | Low |

| Moisture Retention | Yes | No |

| Odor Development | Possible | Rare |

You protect your facility by choosing materials that resist microbial growth. Aluminum return air grilles do not absorb moisture and do not support bacteria or mold.

Cleaning Issues

Cleaning plastic return air grilles presents several challenges. The porous surface traps dust and microbes, making it hard for you to remove all contaminants. You may need to scrub the grille or use strong disinfectants, which can damage the plastic over time. Frequent cleaning can cause the plastic to crack, warp, or discolor.

Plastic grilles also react poorly to many cleaning agents used in cleanroom applications. Some chemicals break down the plastic, leading to surface damage and reduced lifespan. You may find that plastic grilles lose their shape or develop gaps, which allow unfiltered air to bypass the system.

- You spend more time and effort cleaning plastic grilles.

- You risk damaging the grille with harsh chemicals.

- You may need to replace plastic grilles more often due to wear from cleaning.

Tip: If you want to reduce cleaning time and improve hygiene, consider switching to an aluminum return air grille. Aluminum grilles resist damage from cleaning and maintain their appearance and performance for years.

By understanding these drawbacks, you can make a better decision for your facility. Aluminum return air grilles provide a reliable, hygienic, and easy-to-maintain solution for cleanroom and controlled environment applications.

Shorter Lifespan

When you choose a plastic return air grille for your cleanroom or controlled environment, you face a much shorter product lifespan compared to aluminum options. Plastic grilles often look appealing at first, but they cannot withstand the daily demands of high-traffic or high-standard facilities. Over time, you will notice signs of wear that affect both performance and compliance.

Plastic materials tend to degrade faster than metals. Exposure to UV light, cleaning chemicals, and temperature changes causes plastic to become brittle. You may see cracks, warping, or discoloration after only a few years of use. In cleanroom applications, even small defects in your return air grille can compromise air quality and regulatory compliance.

Note: A damaged or warped grille can create gaps that allow unfiltered air to bypass your HVAC system. This puts your clean environment at risk.

You will likely need to replace plastic grilles more frequently. Each replacement means extra labor, downtime, and cost. If you manage a hospital, laboratory, or food processing plant, you know that interruptions can disrupt critical operations. Frequent replacements also increase your facility’s long-term expenses.

Here is a quick comparison of lifespan between plastic and aluminum return air grilles:

| Material | Typical Lifespan | Maintenance Frequency | Replacement Cost Over 10 Years |

|---|---|---|---|

| Plastic Return Air Grille | 2–5 years | High | High |

| Aluminum Return Air Grille | 10–20+ years | Low | Low |

Plastic grilles also struggle with repeated cleaning. Harsh disinfectants and scrubbing can accelerate surface damage. You may notice that plastic loses its structural integrity, leading to sagging or loose fittings. This not only affects appearance but also reduces the effectiveness of your ventilation system.

Aluminum return air grilles, on the other hand, offer a much longer service life. You benefit from a product that resists corrosion, impact, and chemical exposure. When you invest in aluminum, you reduce the frequency of replacements and lower your total cost of ownership.

If you want a reliable, long-lasting solution for your cleanroom or controlled environment, consider switching to an aluminum return air grille. You will protect your facility, maintain compliance, and save money over time.

Tip: Always factor in the expected lifespan and replacement costs when choosing a return air grille for sensitive applications. A longer-lasting product means fewer disruptions and better air quality for your facility.

return air grille Comparison

Hygiene

You want the highest hygiene standards in your clean environment. Aluminum return air grilles help you achieve this goal. The non-porous surface of aluminum does not trap dust, bacteria, or moisture. You can wipe it clean with ease. This feature reduces the risk of microbial growth and contamination.

Plastic grilles, on the other hand, have tiny pores that hold onto dirt and moisture. These pores make cleaning more difficult. Microbes can hide and multiply in these spaces. Over time, you may notice odors or visible mold on plastic grilles.

When you use an aluminum return air grille, you support a sanitary environment. You meet strict hygiene requirements for hospitals, labs, and cleanrooms. You also make inspections easier because aluminum surfaces show dirt and damage less often.

Tip: Choose aluminum grilles for areas where hygiene is critical. You will spend less time cleaning and reduce the risk of contamination.

Durability

Durability matters when you select a return air grille for your facility. Aluminum grilles offer strong resistance to impact, heat, and cleaning chemicals. They do not crack, warp, or become brittle over time. You can expect them to last for many years, even in demanding environments.

Plastic grilles do not perform as well. They may look fine at first, but exposure to sunlight, cleaning agents, and temperature changes can cause them to degrade. Cracks and warping are common problems. These issues create gaps that allow unfiltered air to enter your space.

Aluminum grilles keep their shape and function. You avoid frequent replacements and reduce downtime. This long lifespan saves you money and keeps your facility running smoothly.

| Feature | Aluminum Grille | Plastic Grille |

|---|---|---|

| Impact Resistance | High | Low |

| Chemical Resistance | High | Moderate |

| Lifespan | 10–20+ years | 2–5 years |

| Warping/Cracking | Rare | Common |

Maintenance

You want equipment that is easy to maintain. Aluminum return air grilles make your job simpler. Their smooth surface allows for quick cleaning. You can remove dust and debris with a soft cloth. You do not need special tools or harsh chemicals.

Plastic grilles require more effort. Their porous surface traps particles, so you may need to scrub or use strong disinfectants. This process can damage the plastic and shorten its lifespan.

Filters at return grilles play a key role in maintenance and air quality. When you use filters, you:

- Continuously clean recirculated air by capturing dust, pollen, mold spores, and allergens.

- Minimize dust entering the ductwork, which reduces potential reservoirs for dust and allergens.

Aluminum grilles support regular filter changes. You can remove and replace filters easily. This practice keeps your HVAC system efficient and extends the life of more expensive filters.

Regular maintenance of aluminum grilles helps you maintain high air quality and reduces long-term costs.

Air Quality

You want the best air quality in your cleanroom or controlled environment. The material of your return air grille plays a direct role in this goal. Aluminum return air grilles help you maintain strict air quality standards. The non-porous surface of aluminum does not shed particles or support microbial growth. You can clean these grilles easily, which keeps dust and contaminants out of your airflow.

Plastic grilles do not perform as well. Over time, plastic can crack or warp. These defects create gaps that allow unfiltered air to bypass your HVAC system. Plastic surfaces can also shed tiny particles, which lowers your air quality. In cleanroom applications, even small amounts of dust or microbes can cause problems for sensitive equipment or processes.

You need a return air grille that supports your filtration system. Aluminum grilles fit tightly and work well with HEPA or ULPA filters. This combination helps you remove airborne particles and maintain positive or negative pressure as needed. You protect your products, staff, and facility by choosing the right grille.

| Air Quality Factor | Aluminum Return Air Grille | Plastic Return Air Grille |

|---|---|---|

| Particle Shedding | Minimal | Moderate to High |

| Microbial Resistance | Excellent | Poor |

| Seal Integrity | Strong | Weak (prone to gaps) |

| Filter Compatibility | High | Variable |

| Regulatory Compliance | Easy | Difficult |

Tip: For the highest air quality, pair your aluminum return air grille with high-efficiency filters and follow a regular cleaning schedule.

You can see that aluminum grilles give you a clear advantage in maintaining clean, safe air. This benefit is essential for hospitals, laboratories, and any cleanroom application where air quality cannot be compromised.

Cost

You may wonder about the cost difference between aluminum and plastic return air grilles. At first glance, plastic grilles seem less expensive. You can find basic plastic return air grilles for as little as $9. Aluminum return air grilles usually start at a higher price, with some models reaching up to $430 depending on size, finish, and customization.

However, you need to look beyond the initial purchase price. Aluminum grilles last much longer than plastic ones. You will replace plastic grilles more often due to cracking, warping, or microbial contamination. Each replacement adds to your long-term costs. Aluminum grilles resist damage and require fewer replacements, which saves you money over time.

| Cost Factor | Aluminum Return Air Grille | Plastic Return Air Grille |

|---|---|---|

| Initial Purchase Price | $30–$430 | $9–$60 |

| Typical Lifespan | 10–20+ years | 2–5 years |

| Maintenance Frequency | Low | High |

| Replacement Costs (10 yrs) | Low | High |

| Total Cost of Ownership | Lower | Higher |

You also save on maintenance with aluminum. The easy-to-clean surface reduces labor costs and downtime. You avoid the expense of harsh chemicals or special cleaning tools. In regulated environments, failing an inspection due to poor air quality or damaged grilles can lead to costly fines or shutdowns. Aluminum grilles help you stay compliant and avoid these risks.

Note: Investing in an aluminum return air grille gives you better value over the life of your facility. You protect your budget, your staff, and your reputation.

When you consider all factors—durability, maintenance, air quality, and compliance—aluminum return air grilles offer the best long-term investment for cleanroom applications and any environment where air quality matters.

Applications

Hospitals

You face strict hygiene requirements in hospitals. Every surface must support infection control. Aluminum return air grilles help you meet these standards. Their non-porous surface does not trap dust or bacteria. You can clean them quickly with standard disinfectants. This feature reduces the risk of hospital-acquired infections.

Regulatory agencies, such as the CDC and Joint Commission, inspect hospitals for cleanliness. You must use equipment that passes these inspections. Aluminum grilles resist corrosion from frequent cleaning. They do not warp or crack, even after years of use. You keep your ventilation system reliable and your patients safe.

Tip: Choose aluminum grilles for operating rooms, isolation wards, and intensive care units. These areas demand the highest level of air purity.

Labs

Laboratories require precise control over air quality. You often work with sensitive experiments or hazardous materials. A return air grille made from aluminum supports your need for contamination control. The smooth surface prevents buildup of chemicals or biological agents.

You can remove and clean aluminum grilles without special tools. This feature saves you time during routine maintenance. Many labs use HEPA filters with their grilles. Aluminum frames hold these filters securely, ensuring no unfiltered air enters the workspace.

| Lab Area | Why Aluminum Grilles? |

|---|---|

| Clean benches | Easy to sanitize, non-shedding |

| Chemical labs | Resistant to corrosion and staining |

| Bio labs | Supports sterile protocols |

You protect your research and staff by choosing the right grille material. Aluminum helps you maintain compliance with safety standards.

Food Processing

Food processing plants must prevent contamination at every step. You need equipment that stands up to moisture, cleaning agents, and temperature changes. Aluminum return air grilles offer the durability and hygiene you require. Their non-porous surface does not absorb food particles or support mold growth.

You can wash aluminum grilles with high-pressure water or steam. They resist rust and do not degrade when exposed to sanitizers. This reliability helps you pass food safety audits and avoid costly recalls.

- Use aluminum grilles in packaging rooms, cold storage, and preparation areas.

- Maintain a regular cleaning schedule to ensure air quality and product safety.

You meet industry regulations and protect your brand reputation by investing in quality ventilation components.

Cleanrooms

Cleanrooms demand the highest standards for air purity and contamination control. You must keep airborne particles, microbes, and dust at the lowest possible levels. The choice of return air grille plays a critical role in maintaining these strict conditions. When you select an aluminum return air grille for your cleanroom applications, you invest in proven performance and compliance.

Aluminum grilles offer a non-porous surface. You can clean them quickly and thoroughly. This feature helps you prevent particle buildup and microbial growth. In cleanrooms, even a small amount of contamination can disrupt sensitive manufacturing or research processes. You need equipment that supports your protocols for regular cleaning and sanitization.

Regulatory agencies, such as ISO and GMP, set clear requirements for cleanroom environments. You must use materials that do not shed particles or support microbial life. Aluminum return air grilles meet these standards. You avoid the risk of failing inspections or audits. You also protect your products and staff from contamination.

Tip: Choose aluminum grilles with removable faces. You can access filters easily and replace them without disturbing the cleanroom environment.

You benefit from the durability of aluminum. The metal resists corrosion from cleaning agents and humidity. You do not need to worry about warping or cracking, which can happen with plastic grilles. This reliability means fewer replacements and less downtime for your facility.

Consider the following table to compare aluminum and plastic grilles in cleanroom applications:

| Feature | Aluminum Return Air Grille | Plastic Return Air Grille |

|---|---|---|

| Particle Shedding | Minimal | Moderate |

| Microbial Resistance | Excellent | Poor |

| Cleaning Frequency | Low | High |

| Regulatory Compliance | Easy | Difficult |

| Lifespan | 10–20+ years | 2–5 years |

You can customize aluminum return air grilles to fit your cleanroom layout. You select the size, finish, and filter compatibility that matches your needs. Many suppliers offer antimicrobial coatings or powder finishes for extra protection. You can also request laser-etched identification tags to track maintenance schedules.

Cleanroom managers trust aluminum grilles for their reliability and compliance. You maintain strict air quality, reduce maintenance costs, and support your facility’s reputation for excellence. If you want to meet the highest standards in cleanroom applications, aluminum return air grilles are the preferred choice.

You show your commitment to quality and safety when you choose aluminum products for your cleanroom ventilation system.

Choosing the Right Grille

Environment

You need to match your return air grille to the environment where you plan to install it. Cleanrooms, hospitals, and laboratories require strict control over air quality and contamination. In these settings, you should choose a grille with a non-porous surface and high durability. Aluminum grilles work best because they resist corrosion, do not support microbial growth, and withstand frequent cleaning. If you manage a food processing plant, you also need a grille that can handle moisture and harsh cleaning agents. Aluminum grilles maintain their shape and performance in these demanding conditions.

For less critical environments, such as offices or light-duty areas, you might consider other materials. However, if you want to ensure long-term reliability and compliance with hygiene standards, aluminum remains the top choice. You protect your facility and the people inside by selecting a grille that matches your environment’s needs.

Budget

You want to make a smart investment when choosing a return air grille. The initial cost often influences your decision, but you should also consider long-term expenses. Plastic grilles cost less at first, but they have a shorter lifespan and higher maintenance needs. Aluminum grilles require a higher upfront investment, but they last much longer and need less maintenance. Over time, you save money by choosing a more durable product.

Here is a comparison to help you decide:

| Material | Initial Cost | Lifespan | Maintenance Cost | Total Cost Over 10 Years |

|---|---|---|---|---|

| Plastic | Low | 5-7 years | High | $1,000-$2,000 |

| Aluminum | Moderate | 20-30 years | Low | $800-$1,500 |

You see that aluminum grilles offer better value over the long term. If you manage a facility with strict air quality requirements, investing in aluminum helps you avoid frequent replacements and unexpected costs. Many suppliers, such as those featured on cleanroomsdoors.com, offer a range of aluminum return air grilles with prices that fit different budgets and applications.

Tip: Always consider the total cost of ownership, not just the purchase price. A higher-quality grille can save you money and trouble in the future.

Compliance

You must meet specific compliance requirements when installing return air grilles in regulated environments. These rules help ensure proper airflow, safety, and air quality. You should pay attention to the following:

- Airflow measurement must be conducted using devices like flow hoods or flow grids at the ventilation fan’s inlet or outlet terminals.

- Compliance can also be shown by installing an exhaust fan and duct system that meets specific design specifications outlined in Table 160.2-H.

- The airflow rating must meet or exceed the values specified in Section 160.2(b)2Avi at a static pressure of at least 0.25 in. of water.

- Local mechanical exhaust systems must have sound ratings in accordance with ASHRAE 62.2 at the minimum airflow rate required.

You need to select a return air grille that supports these requirements. Aluminum grilles often come with documentation and certifications that make compliance easier. You can ask your supplier for details about airflow ratings and compatibility with your HVAC system. By choosing the right grille, you help your facility pass inspections and maintain a safe, healthy environment.

Installation

You want a smooth installation process for your return air grille. Proper installation ensures your HVAC system works efficiently and maintains the clean environment you need. When you choose an aluminum return air grille, you benefit from a lightweight yet sturdy product that simplifies handling and mounting.

Start by measuring the opening where you plan to install the grille. Accurate measurements help you select the right size and avoid air leaks. Most suppliers offer aluminum return air grilles in standard and custom sizes, so you can match your cleanroom or laboratory requirements.

Before installation, inspect the area for dust or debris. Clean the surface to prevent contamination during the process. You should also check that the wall or ceiling structure can support the grille’s weight, especially for larger models.

Follow these steps for a successful installation:

- Position the Grille: Place the aluminum return air grille over the opening. Make sure the louvers face the correct direction for optimal airflow.

- Mark the Mounting Holes: Use a pencil to mark where the screws will go. Double-check alignment to ensure a tight seal.

- Drill Pilot Holes: Drill small holes at the marked spots. This step prevents the wall or ceiling from cracking.

- Secure the Grille: Attach the grille using the provided screws. Tighten them evenly to avoid warping the frame.

- Check the Fit: Run your hand around the edges. You should feel no gaps. A snug fit keeps unfiltered air out and maintains pressure control in cleanroom applications.

- Install the Filter (if applicable): If your aluminum return air grille supports filters, insert the correct type before closing the face. Many models feature a hinged or removable face for easy access.

Tip: Always follow the manufacturer’s instructions for your specific grille model. Some aluminum return air grilles include special mounting brackets or require a particular orientation for cleanroom compliance.

You may want to label the grille with installation and maintenance dates. This practice helps you track filter changes and cleaning schedules, which is essential in regulated environments.

If you need to install multiple grilles, create a checklist to ensure consistency across your facility. Proper installation not only improves air quality but also extends the life of your aluminum return air grille.

When you invest in professional installation, you reduce the risk of errors and ensure your cleanroom or laboratory meets all regulatory standards. Reliable suppliers often provide technical support or installation guides. You can contact them for advice on best practices or troubleshooting.

A well-installed aluminum return air grille supports your cleanroom applications by delivering consistent airflow, easy maintenance, and long-term durability. You protect your investment and maintain the highest standards for air purity and compliance.

You want the best for your clean environment. Aluminum stands out as the top choice for a return air grille because it supports hygiene, resists damage, and lasts for years. You protect your facility and meet strict standards when you choose this material. Assess your needs and talk with cleanroom experts before making a decision. For sensitive spaces, aluminum grilles offer the most reliable solution.

FAQ

What makes an aluminum return air grille better for cleanroom applications?

You get a non-porous surface with aluminum. This helps you prevent dust and microbes from building up. You clean it easily and meet strict hygiene standards. Aluminum return air grilles also last longer in demanding cleanroom environments.

How often should you clean or replace filters in a return air grille?

You should check and replace filters every 1–3 months. Regular maintenance keeps your air quality high and your HVAC system efficient. Clean filters help you avoid contamination in cleanroom applications.

Can you use aluminum return air grilles in food processing areas?

Yes, you can. Aluminum resists corrosion and stands up to frequent cleaning. You maintain hygiene and meet food safety standards. Many food processing facilities choose aluminum return air grilles for these reasons.

Do aluminum return air grilles support HEPA or ULPA filters?

You can use most aluminum return air grilles with HEPA or ULPA filters. This compatibility helps you achieve the highest air purity in cleanroom applications. Always check the grille’s specifications for filter size and type.

Are aluminum return air grilles more expensive than plastic ones?

You pay more upfront for aluminum. However, you save money over time because aluminum grilles last longer and need less maintenance. You also reduce the risk of costly contamination in sensitive environments.

How do you install an aluminum return air grille?

You measure the opening, position the grille, and secure it with screws. Many models feature a removable face for easy filter changes. Always follow the manufacturer’s instructions for best results.

Can you customize aluminum return air grilles for your facility?

Yes, you can. Suppliers offer custom sizes, finishes, and features. You can request antimicrobial coatings or special louver patterns. Customization ensures your return air grille fits your cleanroom or laboratory needs.

Why do regulatory agencies prefer aluminum grilles in clean environments?

Regulatory agencies trust aluminum because it does not shed particles or support microbial growth. You meet compliance standards more easily with aluminum return air grilles. This helps you pass inspections and protect your facility’s reputation.

-

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment -

Top Aluminium Profile Manufacturers in China: Leading the Global Market

Top Aluminium Profile Manufacturers in China: Leading the Global Market -

The Evolution of Air Tight Sliding Doors

The Evolution of Air Tight Sliding Doors -

AHU Aluminium Profile: A Comprehensive Guide

AHU Aluminium Profile: A Comprehensive Guide -

The Importance of Choosing the Right Cleanroom Door in Vietnam

The Importance of Choosing the Right Cleanroom Door in Vietnam -

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety -

.jpg) The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities!

The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities! -

Unlock the Possibilities with AJ Manufacturing Doors

Unlock the Possibilities with AJ Manufacturing Doors -

Make a Statement with Manufactured Home Interior Doors!

Make a Statement with Manufactured Home Interior Doors! -

what is aluminum profile? Aluminum Profiles for Your Home is the best option

what is aluminum profile? Aluminum Profiles for Your Home is the best option

-

What Is a Return Air Vent and Why Does It Matter in HVAC

What Is a Return Air Vent and Why Does It Matter in HVAC -

Top Materials for Durable Pharma Clean Room Doors

Top Materials for Durable Pharma Clean Room Doors -

Hospital Cleanroom Door Design Requirements

Hospital Cleanroom Door Design Requirements -

Swing Doors vs Standard Doors: Which Is Right for Your Facility

Swing Doors vs Standard Doors: Which Is Right for Your Facility -

Cleanroom Door Materials Explained: Key Types and Applications

Cleanroom Door Materials Explained: Key Types and Applications -

How Do Different Vent Grills Impact Medical Cleanrooms

How Do Different Vent Grills Impact Medical Cleanrooms -

Controlled Environment vs Air Clean Room Differences Explained

Controlled Environment vs Air Clean Room Differences Explained -

How to Extend the Life of Your Exterior Steel Door

How to Extend the Life of Your Exterior Steel Door -

What Are the Best Materials for AC Vent Covers

What Are the Best Materials for AC Vent Covers -

Ceiling Vent Covers Labeled Fire-Rated? Here’s How to Verify

Ceiling Vent Covers Labeled Fire-Rated? Here’s How to Verify

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.

Speak Your Mind