The Benefits of an Aluminum Clean Room

- By:hqt

- 2023-01-06

- 29

Clean rooms are essential for many industries, including pharmaceutical, healthcare, and semiconductor manufacturing. They are required to maintain a sterile environment to ensure the safety of products and workers. One of the most popular materials used in clean room construction is aluminum. In this blog, we’ll discuss the benefits of an aluminum clean room and the factors to consider when designing one.

What is an aluminum clean room?

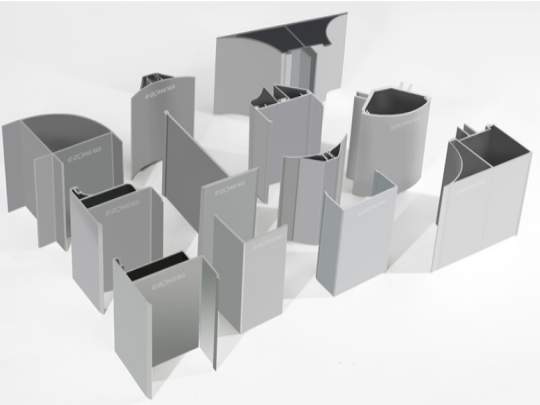

An aluminum clean room is an enclosed space that is designed and constructed to maintain a specific level of environmental control. It is built using aluminum walls and ceilings and is equipped with air filtration systems and other technologies to eliminate contaminants from the air. Aluminum is the ideal material for clean rooms as it is lightweight, durable, and resistant to temperature and humidity fluctuations.

Benefits of an aluminum clean room

There are many benefits to using aluminum for clean room construction. It is a strong material that is resistant to corrosion, making it ideal for a wide range of applications. Aluminum is also easy to clean and maintain, which is essential for ensuring that the clean room environment is free from contaminants. Additionally, aluminum is non-magnetic, which is important for certain applications where magnetic fields could interfere with the accuracy of measurements.

Advantages of aluminum over other materials for clean rooms

Aluminum has some clear advantages over other materials used in clean room construction, such as steel and plastic. Steel is susceptible to corrosion, which can be a problem in certain environments. Plastic is not as strong as aluminum and can be easily damaged. Aluminum is also much lighter than steel and is easier to work with during the construction process.

Aluminum clean room design

When designing an aluminum clean room, there are a few important factors to consider. The size and shape of the room need to be carefully planned to maximize the efficiency of the air filtration system. Additionally, the walls, ceilings, and floors need to be sealed properly to ensure that they are airtight. The air filtration system should be designed to meet the requirements of the environment and the type of work that will be done in the clean room.

Factors to consider when designing an aluminum clean room

When designing an aluminum clean room, several factors need to be taken into consideration. The size and shape of the room should be planned carefully to maximize the efficiency of the air filtration system. The walls, ceilings, and floors should be sealed properly to ensure that they are airtight. The air filtration system should be designed to meet the requirements of the environment and the type of work that will be done in the clean room. Additionally, the room should be designed to minimize the risk of contamination from outside sources.

Aluminum clean room installation

Once the design of the aluminum clean room has been finalized, the installation process can begin. During this process, the walls, ceilings, and floors should be sealed properly to ensure that they are airtight. Additionally, the air filtration system should be installed and tested to ensure that it meets the requirements of the environment. The installation process should also include a thorough inspection of the clean room to ensure that it meets all safety requirements.

Aluminum clean room maintenance

Maintaining an aluminum clean room is essential to ensure that it remains a safe and sterile environment. The air filtration system should be regularly inspected and tested to ensure that it is functioning properly. Additionally, all surfaces in the clean room should be regularly cleaned and disinfected to eliminate any potential contaminants. Any damaged parts of the clean room should be repaired or replaced immediately to prevent any safety hazards.

Aluminum clean room safety

Safety is of the utmost importance when it comes to aluminum clean rooms. All workers in the clean room should follow the safety protocols and wear the necessary protective equipment to prevent the spread of contaminants. Additionally, the air filtration system should be regularly inspected and tested to ensure that it is functioning properly.

The cost of an aluminum clean room

The cost of an aluminum clean room will depend on the size and complexity of the design. Generally, the larger and more complex the clean room, the more expensive it will be to construct. Additionally, the cost of the air filtration system, labor, and other materials will need to be taken into account when calculating the total cost.

Conclusion

Aluminum is a popular material for clean room construction due to its strength, durability, and resistance to corrosion. It is also lightweight and easy to clean and maintain, making it ideal for a wide range of applications. When designing an aluminum clean room, the size and shape of the room, the air filtration system, and the safety protocols need to be taken into consideration. The cost of an aluminum clean room will depend on the size and complexity of the design. With the right design, an aluminum clean room can provide a safe and sterile environment for important work.

-

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment

-

Top Aluminium Profile Manufacturers in China: Leading the Global Market

-

The Evolution of Air Tight Sliding Doors

-

AHU Aluminium Profile: A Comprehensive Guide

-

The Importance of Choosing the Right Cleanroom Door in Vietnam

-

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety

-

The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities!

-

Unlock the Possibilities with AJ Manufacturing Doors

-

Make a Statement with Manufactured Home Interior Doors!

-

what is aluminum profile? Aluminum Profiles for Your Home is the best option

-

Efficiency Meets Elegance in Industrial Cleanroom Aluminum Extrusion Solutions

-

How Aluminium Doors Are Transforming Hospital Security and Accessibility

-

What Are the Technology Behind the Hospital Double Doors

-

Double Leaf Cleanroom Door Improves Workflow Efficiency in Medical Device Assembly Lines

-

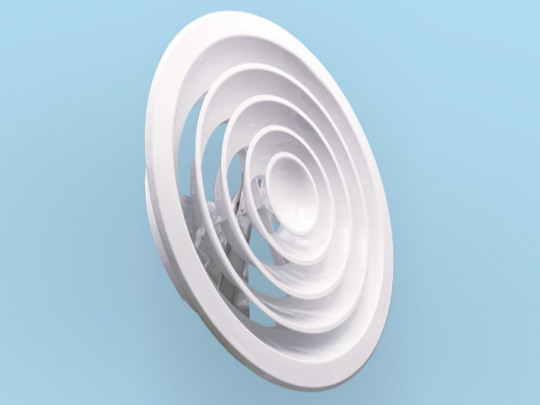

How the Right Drop Ceiling Air Vent Diffuser Cover Transforms Your Ceiling

-

How Air Vent Diffuser Ceiling Choices Impact Energy Efficiency

-

Behind the Lab Cleanroom Door: Cutting-Edge Solutions for Sterile Science Spaces

-

Customized Door Solutions That Meet Every Unique Need

-

Why Cleanroom Door Buyers Worldwide Are Turning to China's Aluminum Factories

-

Cleanroom Roll-Up Doors: Small Feature, Big Impact in Contamination Control

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.

.jpg)

Speak Your Mind