Aluminum Clean Room Profile: Redefining Cleanliness and Durability

- By:hqt

- 2024-05-09

- 29

Clean rooms stand as the backbone of industries where precision and sterility are paramount. These controlled environments find applications in diverse sectors like pharmaceuticals, biotechnology, electronics, and aerospace, ensuring the integrity of processes and products. At the core of every clean room lies meticulous design and construction, with aluminum clean room profiles emerging as indispensable components.

Understanding Clean Room Requirements

1.1 Different Clean Room Classifications

Clean rooms adhere to specific classifications outlined by the International Organization for Standardization (ISO). These classifications, ranging from ISO Class 1 to ISO Class 9, dictate the permissible levels of airborne particles per cubic meter. Higher ISO classes necessitate stricter controls, crucial for industries like semiconductor manufacturing and biotechnology where even minute contaminants can compromise processes and products.

1.2 Importance of Controlled Environments

The stringent cleanliness requirements in clean rooms stem from the sensitivity of processes conducted within them. In pharmaceutical manufacturing, for instance, the presence of contaminants can lead to compromised drug efficacy and patient safety. Similarly, in semiconductor fabrication, even a speck of dust can render electronic components defective, emphasizing the criticality of maintaining controlled environments.

1.3 Standards and Regulations

Clean room design and operation are governed by stringent standards and regulations to ensure adherence to cleanliness protocols. Organizations like the International Standards Organization (ISO) and regulatory bodies such as the Food and Drug Administration (FDA) enforce guidelines to safeguard product quality and consumer health. Compliance with these standards is non-negotiable for industries operating within clean room environments.

Advantages of Aluminum Clean Room Profile

2.1 Introduction to Aluminum

Aluminum emerges as the material of choice for a clean room profile owing to its remarkable properties. Its lightweight nature facilitates easy handling and installation, reducing construction time and costs. Moreover, aluminum's corrosion resistance ensures longevity, vital for environments requiring frequent sterilization and chemical exposure. Additionally, its recyclability aligns with sustainability goals, making it an eco-friendly option for clean room construction.

2.2 Key Advantages

a. Lightweight Nature: Aluminum's low density makes it ideal for constructing structures within clean rooms without adding excessive weight. This characteristic simplifies transportation and installation processes, contributing to overall project efficiency.

b. Corrosion Resistance: Clean rooms often undergo rigorous cleaning procedures involving harsh chemicals and disinfectants. Aluminum's innate resistance to corrosion ensures durability, maintaining structural integrity over prolonged usage.

c. Recyclability: Sustainability is increasingly becoming a focal point across industries. Aluminum's recyclability enables the fabrication of clean room profiles with minimal environmental impact, aligning with corporate responsibility initiatives.

2.3 Contribution to Cleanliness

The non-porous surface of aluminum clean room profiles inhibits the accumulation of contaminants, ensuring hygienic environments. Furthermore, their smooth surface facilitates easy cleaning, minimizing the risk of microbial growth and maintaining stringent cleanliness standards. This attribute is particularly crucial in industries like pharmaceuticals and biotechnology, where sterility is paramount.

Customization and Flexibility of Aluminum Clean Room Profile

3.1 Versatility in Design

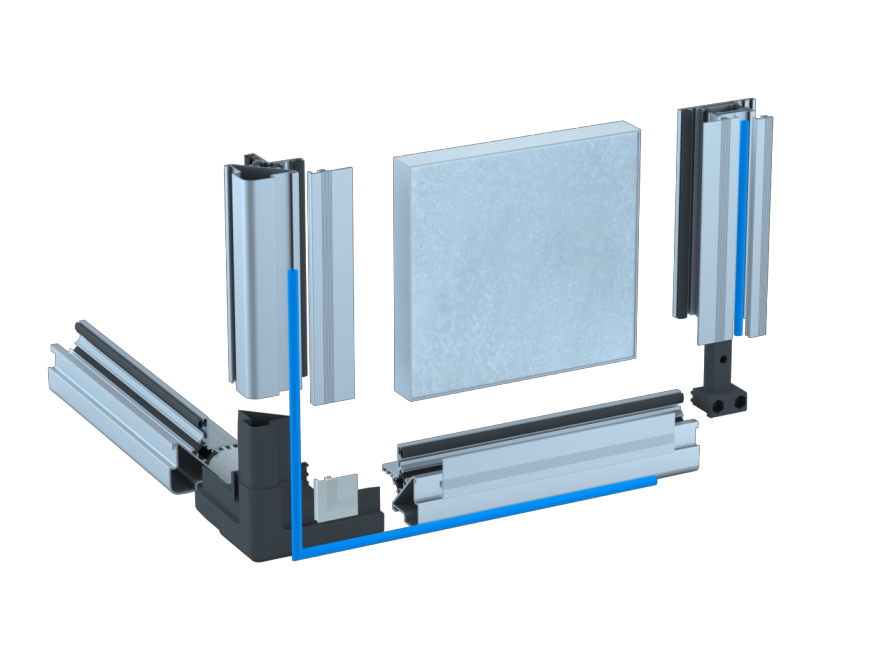

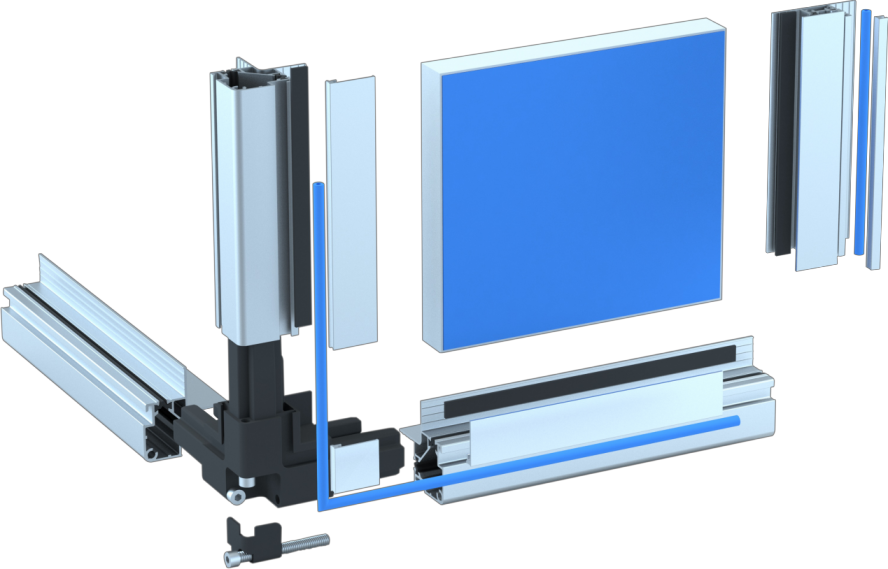

Aluminum clean room profile offers unparalleled flexibility, catering to a wide array of design requirements and specifications. Their modular nature allows for seamless integration into diverse clean room layouts, accommodating specific needs with ease. Whether it's creating partitions, shelving units, or equipment enclosures, aluminum profiles provide the framework for tailored solutions that optimize space utilization and functionality within clean room environments.

3.2 Ease of Customization

One of the standout features of the Aluminum Clean Room Profile is its ease of customization. Manufacturers like E-ZONG offer a variety of profile shapes, sizes, and finishes, enabling precise adaptation to unique clean room requirements. From simple adjustments in length to complex configurations, aluminum profiles can be tailored to fit seamlessly into any clean room design. This customization capability empowers clean room engineers and designers to create efficient, ergonomic, and aesthetically pleasing environments that enhance productivity and workflow.

3.3 Integration with Clean Room Components

The Aluminum Clean Room Profile serves as the backbone for integrating various clean room components such as walls, ceilings, and flooring. Their modular design allows for effortless connection and alignment with other structural elements, facilitating swift assembly and installation. Whether it's suspending ceiling panels, mounting lighting fixtures, or securing wall panels, aluminum profiles provide the versatility needed to seamlessly incorporate these essential components into the clean room infrastructure.

Durability and Longevity of Aluminum Clean Room Profile

4.1 Durability in Demanding Environments

Aluminum Clean Room Profile exhibits exceptional durability, capable of withstanding the rigors of demanding clean room environments. Their inherent resistance to corrosion, rust, and degradation ensures longevity even in the presence of chemicals, moisture, and other harsh conditions. This durability is essential for maintaining structural integrity and cleanliness over extended periods, safeguarding critical processes and equipment within the clean room.

4.2 Resilience to Harsh Conditions

Clean rooms often entail exposure to a myriad of challenges, including chemical spills, frequent sterilization procedures, and high humidity levels. Aluminum profiles excel in such environments, maintaining their structural integrity and performance despite prolonged exposure to these harsh conditions. Their resilience minimizes the risk of deterioration or degradation, ensuring uninterrupted operation and compliance with cleanliness standards in the long run.

4.3 Long Service Life and Cost Savings

The longevity of the Aluminum Clean Room Profile translates into significant cost savings over its lifecycle. Unlike alternative materials prone to deterioration or wear, aluminum profiles require minimal maintenance and replacement, reducing downtime and associated expenses. Their enduring performance and reliability offer peace of mind to facility managers and operators, contributing to operational efficiency and sustainability in clean room operations.

Installation and Maintenance Considerations for Aluminum Clean Room Profile

5.1 Installation Process and Handling

Installing aluminum clean room profiles is a straightforward process, thanks to their lightweight nature and modular design. E-ZONG provides comprehensive installation guidelines and support, ensuring smooth integration into clean room construction projects. Their ease of handling minimizes labor requirements and installation time, facilitating the timely completion of clean room facilities with minimal disruptions.

5.2 Minimal Maintenance Requirements

Aluminum profiles boast minimal maintenance requirements, making them an ideal choice for clean room applications. Routine cleaning with mild detergents and non-abrasive materials is sufficient to preserve their cleanliness and appearance. Periodic inspections for signs of wear or damage ensure early detection and prompt resolution, prolonging the lifespan of aluminum profiles and maximizing their effectiveness in maintaining clean room environments.

5.3 Maximizing Lifespan and Effectiveness

Proper installation and maintenance practices are crucial for maximizing the lifespan and effectiveness of aluminum clean room profiles. Following manufacturer guidelines for handling, installation, and cleaning is essential to ensure optimal performance and longevity. Regular inspections and proactive maintenance measures, such as lubricating joints and tightening connections, help prevent issues and ensure continued compliance with cleanliness standards.

Conclusion

Aluminum clean room profile represents an integral component of clean room construction, offering a myriad of advantages crucial for maintaining controlled environments. From their lightweight nature to corrosion resistance and recyclability, aluminum profiles embody the characteristics essential for industries reliant on pristine conditions. As industries continue to push the boundaries of innovation, the role of aluminum clean room profiles in ensuring cleanliness, durability, and versatility remains indisputable.

-

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment -

Top Aluminium Profile Manufacturers in China: Leading the Global Market

Top Aluminium Profile Manufacturers in China: Leading the Global Market -

The Evolution of Air Tight Sliding Doors

The Evolution of Air Tight Sliding Doors -

AHU Aluminium Profile: A Comprehensive Guide

AHU Aluminium Profile: A Comprehensive Guide -

The Importance of Choosing the Right Cleanroom Door in Vietnam

The Importance of Choosing the Right Cleanroom Door in Vietnam -

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety -

.jpg) The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities!

The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities! -

Unlock the Possibilities with AJ Manufacturing Doors

Unlock the Possibilities with AJ Manufacturing Doors -

Make a Statement with Manufactured Home Interior Doors!

Make a Statement with Manufactured Home Interior Doors! -

what is aluminum profile? Aluminum Profiles for Your Home is the best option

what is aluminum profile? Aluminum Profiles for Your Home is the best option

-

Guide to Doors Clean Room: Ensuring Contamination Control

Guide to Doors Clean Room: Ensuring Contamination Control -

Introducing Guangdong Clean Room Aluminum Company: E-ZONG

Introducing Guangdong Clean Room Aluminum Company: E-ZONG -

Cost-Effectiveness of Bulk Purchasing Air Diffuser

Cost-Effectiveness of Bulk Purchasing Air Diffuser -

Makeup Air Handling Unit: Here to Know

Makeup Air Handling Unit: Here to Know -

Customizing HVAC Systems Parts for Building Specific Needs

Customizing HVAC Systems Parts for Building Specific Needs -

How Return Air Diffuser Enhances HVAC Efficiency for Your Projects

How Return Air Diffuser Enhances HVAC Efficiency for Your Projects -

Exploring the Versatility of Swing Glass Door

Exploring the Versatility of Swing Glass Door -

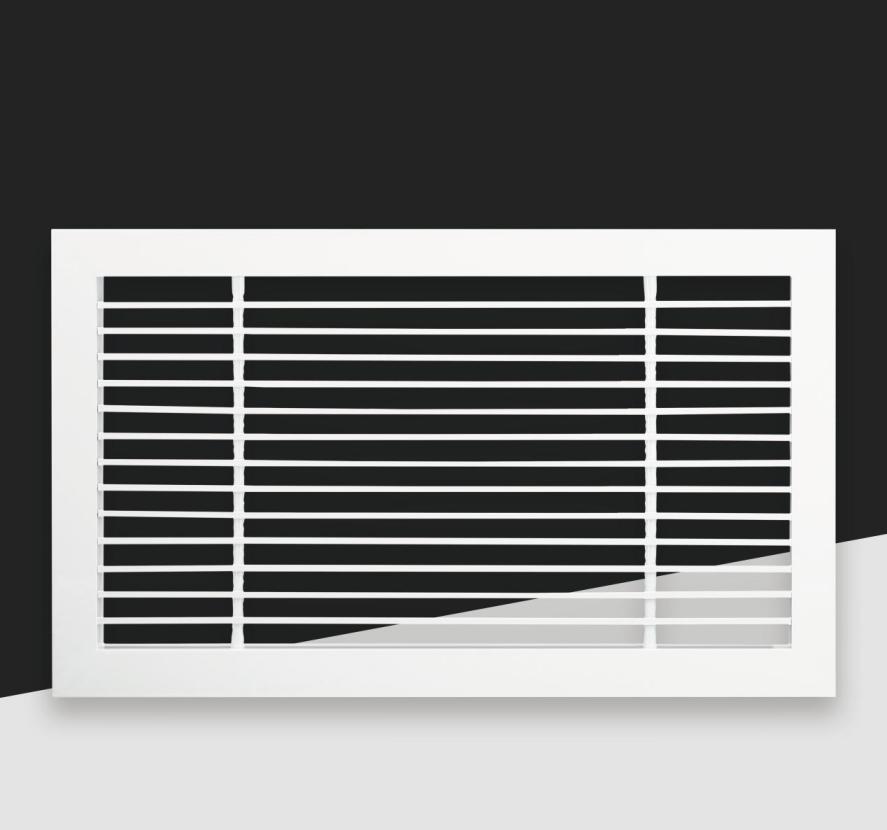

Choosing Quality: Why Linear Diffuser Grille is Essential in Modern Design

Choosing Quality: Why Linear Diffuser Grille is Essential in Modern Design -

Introduction to Clean Room High Speed Doors: Let’s Dive into

Introduction to Clean Room High Speed Doors: Let’s Dive into -

High-Quality Clean Room Double Door for Medical and Health

High-Quality Clean Room Double Door for Medical and Health

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.

Speak Your Mind