Why is Aluminium extrusion clean room important?

- By:hqt

- 2023-05-07

- 29

What exactly is Aluminium extrusion clean room for?

Extrusion clean rooms are specialized buildings made for producing aluminium extrusions in environmental conditions that may be controlled. Clean rooms are required because even minute levels of contamination might interfere with the extrusion process and result in flaws in the final product. To maintain the necessary cleanliness levels, the clean room must be constructed with suitable air filtration and ventilation systems and the right wall, floor, and ceiling material choices. To avoid the build-up of dust and other impurities, the clean room must also be routinely maintained and cleaned. Additionally, to prevent environmental contamination and the taint of the extruded aluminium products, clean room workers must adhere to tight guidelines for gowning, hand washing, and general hygiene.

- Custom shapes made from aluminium alloy are produced by the commonly used manufacturing technique of aluminium extrusion. Although the process is very successful and efficient, it also generates a lot of scraps that need to be recycled or properly disposed of.

- The majority of extrusion facilities have clean rooms, which is crucial to the process's performance. In order to prevent the alloy from becoming polluted by airborne contaminants and other impurities, the process is normally carried out in a cleanroom.

Using an Aluminium Extrusion Clean Room to Ensure Quality:

A clean extrusion room is a unique setting created to lessen the amount of particle matter and other impurities in the air. It is essential to maintain a clean atmosphere to ensure consistent quality of the finished product and achieve the high standards required in many industries where aluminium extrusion is utilized. An aluminium extrusion clean room requires the correct facility design, equipment selection, and employee training to ensure quality. Here are some crucial things to remember:

- Design of the facility:

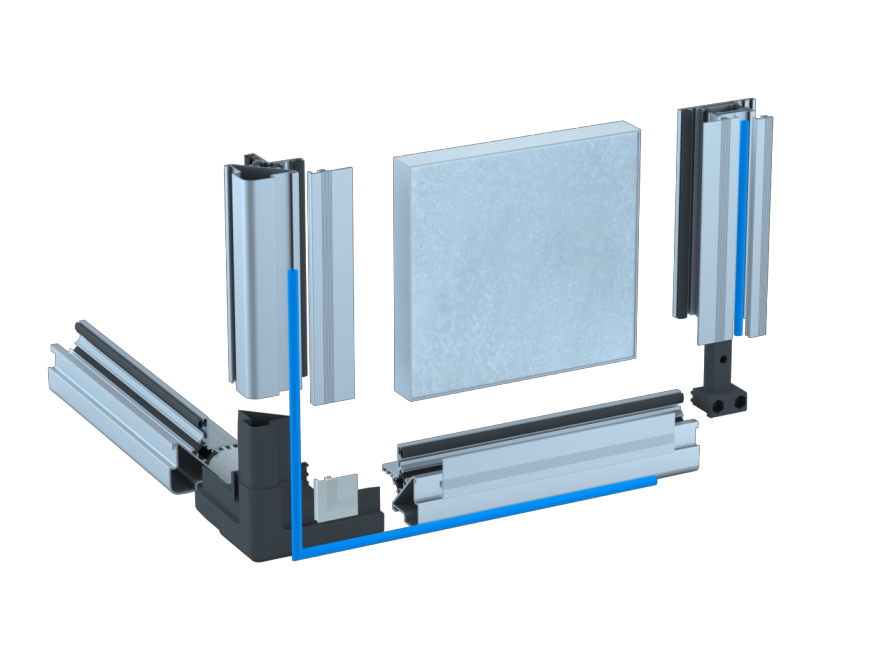

To reduce the amount of dust, pollutants, and other airborne particles, the clean room facility should be planned with the appropriate airflow, air filtration, and ventilation systems. To avoid the build-up of particles, the walls, floors, and ceilings should be constructed of simple materials to clean and disinfect. To ensure the facility continues to satisfy standards for cleanliness, it should also be frequently maintained and inspected.

- Equipment selection:

It is important to use equipment developed and maintained to reduce the production of particles and impurities during the aluminium extrusion process. The equipment should be frequently inspected and cleaned to avoid the build-up of particles and lower the possibility of flaws in the extruded aluminium products.

- Employee education:

Adequate training is necessary to ensure staff members know and abide by the clean room regulations. This includes using the appropriate gowning techniques, cleaning your hands, and following other hygiene rules. Employees should also be taught to see problems and potential contamination concerns in the facility and to report them.

- Quality control:

To ensure that the extruded aluminium products satisfy the requirements and standards, routine quality control tests and inspections should be carried out. This entails gauging important properties, including surface finish and dimensional precision.

Why is Aluminium Extrusion Clean Room Important?

Aluminium is shaped into the desired cross-sectional profile during the manufacturing process, known as extrusion. A press is used to press an aluminium billet through a shaped die after heating it to a certain temperature. The finished extruded aluminium profile can be used in various industries, including aerospace, automotive, and electronics. However, contamination is particularly sensitive to the aluminium extrusion process. Even minute amounts of oil, dust, or other impurities might result in flaws in the final product. This is why having a clean space for aluminium extrusion is crucial. An aluminium extrusion clean room is essential for producing high-quality extruded aluminium products for the following reasons:

- Control of contamination:

Contamination control is the main goal of a clean room. A clean room for aluminium extrusion has a carefully regulated atmosphere to reduce the amount of dust, grime, and other impurities. This is accomplished using ventilation and air filtering systems with suitable materials for the walls, floors, and ceilings. All staff must adhere to stringent guidelines for donning protective gear and washing their hands to prevent contamination. Clean rooms are often kept at a positive pressure to prevent outside air from entering the space.

- Quality of goods is consistent:

A clean room for aluminium extrusion can aid in maintaining consistent product quality. We can produce extruded aluminium goods that adhere to the specifications and quality requirements by managing the environment and reducing contamination. This is crucial in sectors like aerospace and automotive, where product quality and flaws can have major repercussions. E-ZONG may establish a solid reputation for dependability and quality through consistent product quality.

- Improved effectiveness:

Additionally, a clean chamber for aluminium extrusion can increase productivity. We can decrease waste and boost throughput by lowering the likelihood of faults and the requirement for rework. Additionally, by lessening contamination-related wear and tear, a clean room can aid in extending the lifespan of the equipment. This may lower maintenance expenses and improve equipment availability.

- Regulation observance:

Standards and laws for maintaining cleanliness and protecting the environment are prevalent in many businesses. Using a clean room for aluminium extrusion can assist producers in adhering to these rules and specifications. E-ZONG can demonstrate their adherence to these rules and standards by maintaining a clean environment, which can be crucial for landing contracts and keeping customers' trust.

Conclusion:

An aluminium extrusion clean room is a unique setting created to lessen the amount of particle matter and other impurities in the air. Our products are among the highest quality in the industry and are made with a wide variety of CNC machining tools. E-ZONG currently employs over 300 people, and its facility spans more than 30,000 square metres. We have more than 26 years of experience in the development sector and have a strong foundation in project management and quality assurance.

-

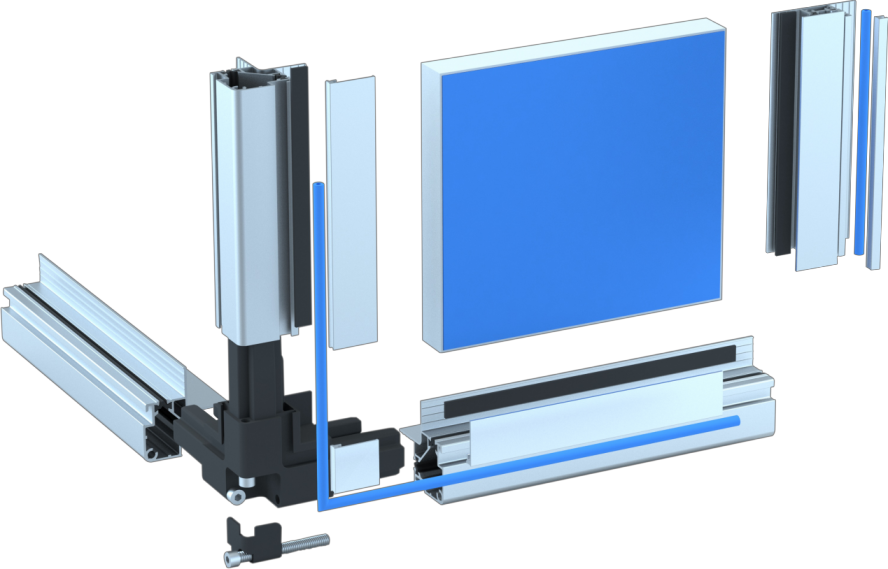

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment

Cleanroom Glass Windows Are The Key to Maintaining a Clean Environment -

Top Aluminium Profile Manufacturers in China: Leading the Global Market

Top Aluminium Profile Manufacturers in China: Leading the Global Market -

The Evolution of Air Tight Sliding Doors

The Evolution of Air Tight Sliding Doors -

AHU Aluminium Profile: A Comprehensive Guide

AHU Aluminium Profile: A Comprehensive Guide -

The Importance of Choosing the Right Cleanroom Door in Vietnam

The Importance of Choosing the Right Cleanroom Door in Vietnam -

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety

The Benefits of Hospital Automatic Doors: Enhancing Efficiency and Safety -

.jpg) The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities!

The Best Bathroom Door Manufacturers - Unlocking Endless Possibilities! -

Unlock the Possibilities with AJ Manufacturing Doors

Unlock the Possibilities with AJ Manufacturing Doors -

Make a Statement with Manufactured Home Interior Doors!

Make a Statement with Manufactured Home Interior Doors! -

what is aluminum profile? Aluminum Profiles for Your Home is the best option

what is aluminum profile? Aluminum Profiles for Your Home is the best option

-

Guide to Doors Clean Room: Ensuring Contamination Control

Guide to Doors Clean Room: Ensuring Contamination Control -

Introducing Guangdong Clean Room Aluminum Company: E-ZONG

Introducing Guangdong Clean Room Aluminum Company: E-ZONG -

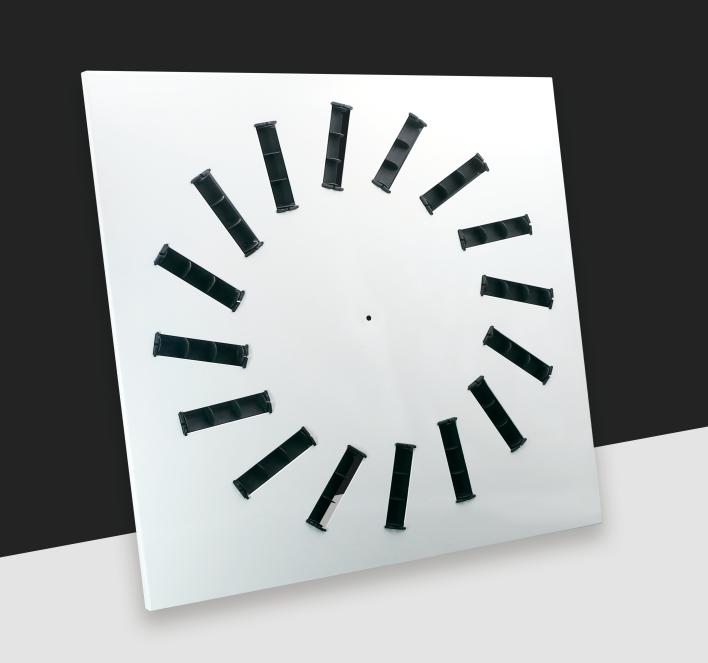

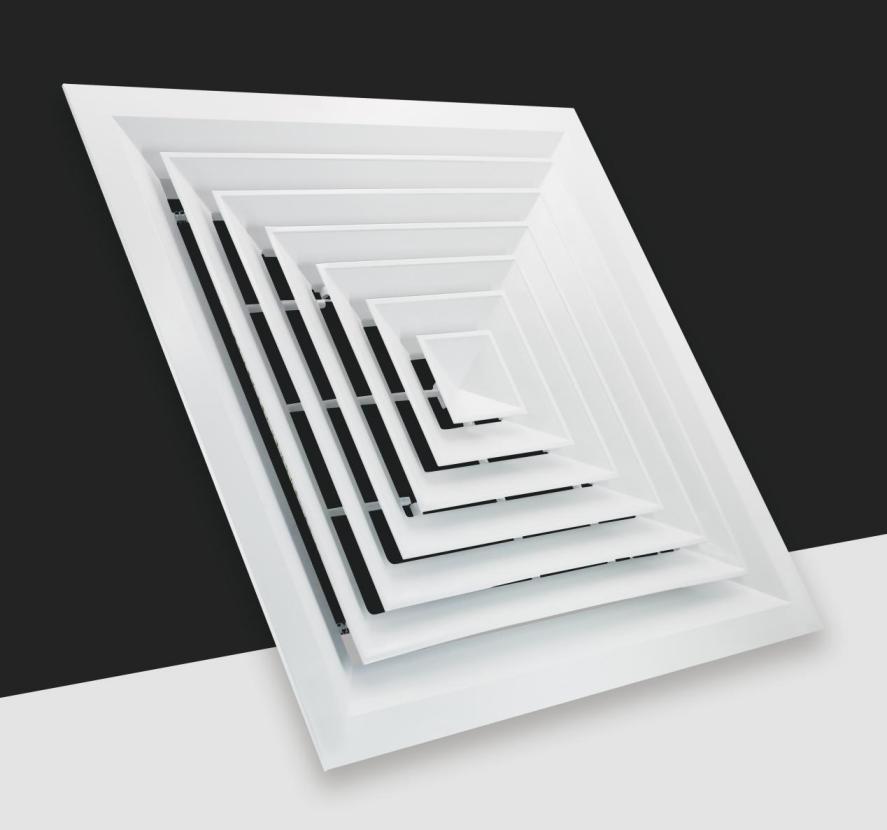

Cost-Effectiveness of Bulk Purchasing Air Diffuser

Cost-Effectiveness of Bulk Purchasing Air Diffuser -

Makeup Air Handling Unit: Here to Know

Makeup Air Handling Unit: Here to Know -

Customizing HVAC Systems Parts for Building Specific Needs

Customizing HVAC Systems Parts for Building Specific Needs -

How Return Air Diffuser Enhances HVAC Efficiency for Your Projects

How Return Air Diffuser Enhances HVAC Efficiency for Your Projects -

Exploring the Versatility of Swing Glass Door

Exploring the Versatility of Swing Glass Door -

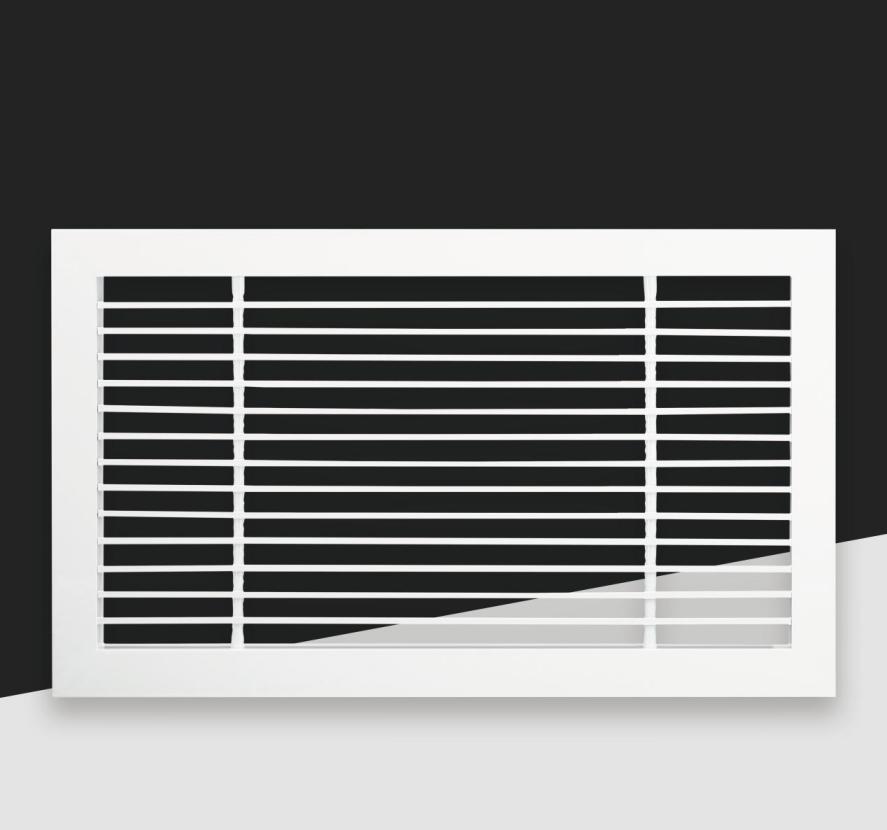

Choosing Quality: Why Linear Diffuser Grille is Essential in Modern Design

Choosing Quality: Why Linear Diffuser Grille is Essential in Modern Design -

Introduction to Clean Room High Speed Doors: Let’s Dive into

Introduction to Clean Room High Speed Doors: Let’s Dive into -

High-Quality Clean Room Double Door for Medical and Health

High-Quality Clean Room Double Door for Medical and Health

Guangzhou Yizhong Aluminum Industry Co., Ltd.

We are always providing our customers with reliable products and considerate services.

We are always providing our customers with reliable products and considerate services.

Speak Your Mind